A. Property of SXBJ-9 Sheet Metal Plate Edge Milling Machine:

1. Position: SXBJ-9 belongs to medium large size model, among the product family of XBJ and SXBJ series Sheet Metal Plate End Milling Machine, which ranges from compact size XBJ-3 or SXBJ-3, model to the largest long stroke SXBJ-18 model;

2. Business Case Volume: Judging from normal distribution theory in statistics, medium large size SXBJ-9 is one of the largest selling volume machine model for sheet metal plate beveling.

B. Working Characteristics of SXBJ-9 Sheet Metal Plate Edge Chamfering Machine:

1. Nature of the SXBJ-9 Sheet Metal Plate Edge Milling Machine:

1) This machine is a kind of entry level machining equipment;

2) It utilizes the same core function element of milling head and facer blade as Milling Machine, but deliver slightly lower level of roughness and precision degree;

2. The workpieces of such equipment for edge milling are various materials sheet metal, or metal plate. In practical application, carbon steel takes most majority, about over 90% of machine workpieces;

3. The Delivery of SXBJ-9 Sheet Metal Plate Edge Milling Machine:

1) Output workpiece of the machine are several types of common seen bevels, or chamfer, which are used as grooves for next step welding, especially on steel plate with thickness bigger than 15mm;

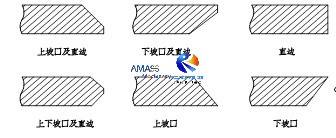

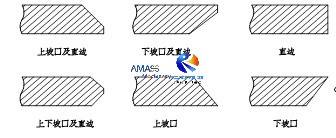

2) The common seen grooves machined are V/ X bevels at top or bottom edges of steel plate: (Fig.1)

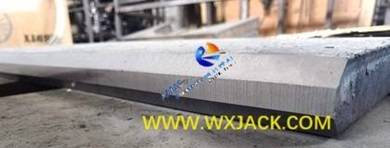

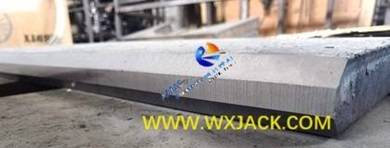

3) The actual finished X groove beveled steel plate output from Wuxi JACK Sheet Metal Plate Edge Milling Machine: (Fig.2)

4. Main Working Action of the SXBJ-9 Sheet Metal Plate End Milling Machine:

1) The primary working motion on edge milling is horizontal X axis movement of milling head along the entire length of worktable, so that its facer blade can carry out edge grooving in the process;

2) Milling head moves along working table and workpiece of the Edge Chamfering Machine, for performing edge grooving task at the same time: (Fig.3)

5. Enforcement Unit of the SXBJ-9 Sheet Metal Plate End Milling Equipment:

1) For this reason, milling head is the central function element in the machine;

2) In Wuxi JACK delivered machine product, the milling head has high power of 7.5kW for conventional models and 11kW for special models, with 6/ 9 shifts of spindle revolutionary speed adjustment;

3) These capabilities are much more superior than that of competitors' delivered machine for edge milling;

4) The top quality Taiwan produced E-LONG brand milling head equipped in Wuxi JACK Sheet Metal Plate Edge Milling Machine: (Fig.4)

6. Working Speed during Running of the SXBJ-9 Sheet Metal Plate Edge Chamfering Machine:

1) The edge milling working speed can be adjusted continuously within the range of 130mm~ 1000mm/min.;

2) Such adjustment is based on workpiece condition and required bevel types, and realized by turning speed knob on operating pendant;

3) This working speed is also displayed in real time on operating pendent of corresponding milling carriage during working period;

4) The working speed show and modulation: (Fig.5)

C. Working Mode of SXBJ-9 Double Heads Sheet Metal Plate Edge Milling Machine:

1. Edge Milling Efficiency in SXBJ-9 Plate Edge Chamfering Machine:

Configuration style of double milling heads is very useful for raising and guaranteeing production efficiency. This can be embodied in below two aspects:

1) Shorten the cycle time for edge milling along stroke of workpiece;

2) Completes up and lower edge beveling by means of one time stroke of milling head movement;

2. Two Working Ways in SXBJ-9 double heads Plate Edge Milling Machine:

1) Delivering top and bottom beveling with one time pass: The 2 sets of milling units work together in pair, which means, one following the other. The leading milling head is responsible for making top edge bevels, and the following milling head is responsible for making bottom bevels;

2) Make the same piece of bevel together: Or, the 2 sets of milling units share the valid stroke, and each one is responsible for fulfilling sheet edge beveling task of its “Duty range”. Please note here that the 2 sets of the milling units travel in the same direction along machine work table, instead of traveling toward each other;

D. Technical Parameters of SXBJ-9 Sheet Metal Plate Edge Milling Machine:

Model Technical Parameter | SXBJ-9 Double Heads Sheet Metal Plate Edge Chamfering Machine |

Max. Plate Beveling Length | 9000 mm |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Milling Head Quantity | 2 sets |

Plate thickness for Sheet Metal Chamfering | 6∼100 mm |

Milling Angle of Top Milling unit | 0° to +80° |

Milling Angle of Down Milling unit | -45° to 0° |

Edge Milling Speed | 130∼1000 mm/min. (VFD, Inverter Control) |

High Speed of Idle | 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200mm For delivery) |

Quantity of Hydraulic Jacks | 12 pieces |

Hydraulic Rated Pressure | 5.5 MPa |

Hydraulic Working Pressure | 3.5 MPa |

Hydraulic System Flowrate | 47 L/min. |

Worktable Width | 450 mm |