A. Function, Usage and Application of Z Series I H Beam Assembly Machine:

1. Task of Z Series I H Beam Assembly and Tack Welding Machine:

1) Delivery and Main Job: Z series I H Beam Assembling Machine is used for assembling two pieces of flange and one piece of web into the structure of “H” or “I”, and carry out tack welding (or called CO2 stitch welding), to strengthen the structure of the assembled I H Beam at the same time;

2) In this sense, this equipment also has the full name of I H Beam Assembling and Tack Welding Machine;

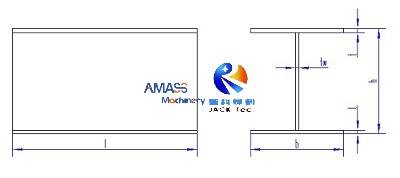

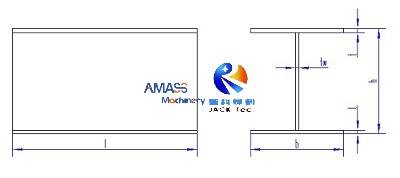

3) Design structure of I H Beam fabricated from I H Beam Assembling Machine: (Fig.1)

4) Working site of Wuxi JACK Z15 I H Beam Assembling and Tack Welding Machine: building up assembled H Beam: (Fig.2)

2. Application and Importance: Z series I H Beam Assembly Machine is the 1st set of major core equipment in I H Beam Production Line, for building up basic skeleton of welding I H Beam.

B. Process Technology of I H Beam Assembly and Tack Welding Machine:

1. From T Beam to H Beam in I H Beam Assembly Machine:

In one full operation period of I H Beam Assembly and Tack Welding Machine:

1) First web and the first piece of flange are fit up and spot welded into T Beam;

2) Then, the 2nd piece of flange is loaded onto the I H Beam Assembling Machine, then T Beam is further fabricated into H Beam (I Beam);

3) Control Unit: The work logic of entire H Beam fitting up and tack welding is controlled with PLC (Programmable logic controller);

2. Main Equipment in I H Beam Production Line:

a) Importance: In the process technology of welding I H Beam Production Line, the I H Beam Assembly and Tack Welding Machine is the first set of core H Beam Production Machine;

b) The other two critical equipment subsequent to the I H Beam Assembling Machine:

1) LHA / LHC / LHT series H Beam Welding Machine (H Beam Submerged Arc Welding Machine);

2) HYJ / YTJ series H Beam Straightening Machine (H Beam Flange Straightening Machine).

C. Standard Models and Classification on Z Series I H Beam Assembling Machine:

There are several ways of classifying on the I H Beam Assembly Machine:

1. Depending on the Max. Height of H Beam Web from I H Beam Assembly Machine:

a) Denote on H Beam Cross section from I H Beam Assembling Machine: (Fig.3)

b) Corresponds to the “h” value in the above sketch, the Z series I H Beam Assembly and Tack Welding Machine has three standard models of Z15, Z18, Z20:

1) Z15: The produced max. H Beam web height is 1,500mm;

2) Z18: The produced max. H Beam web height is 1,800mm;

3) Z20: The produced max. H Beam web height is 2,000mm;

4) The max. model of Z30: Max. H Beam web height of 3,000mm;

2. Way of Flange and Web Fit Up in I H Beam Assembling Machine:

Depending on alignment style of web and flange, the Z series I H Beam Assembling and Tack Welding Machine has two major types of:

1) Automatic self alignment type I H Beam Assembly Machine: H Beam fitting up and alignment is fulfilled with PLC control: (Fig.4)

2) Manual alignment type I H Beam Assembly Machine: One side of upright web is clamped, and the other side of the upright web is aligned with horizontal flange by means of manual turning leadscrew. This alignment form depends on proficient skill and experience of operators for I H Beam Assembling Machine;

3. Stitch Welding Mode in I H Beam Assembly and Tack Welding Machine:

Depending on tack welding mode selected, the Z series I H Beam Assembling and Tack Welding Machine has two major groups of:

1) Automatic tack welding I H Beam Assembly Machine: The CO2 stitch welding is controlled and performed with CO2 welding power supply. Under such condition, the I H Beam Assembly Machine needs only 1 operator, and there is no strict requirement on welding skill of the operator:

Automatic I H Beam Assembly Machine deployed in I H Beam Production Line: (Fig.5)

2) Manual tack welding type I H Beam Assembly and Tack Welding Machine: The CO2 tack welding is performed by operator. Under such condition, one set of the I H Beam Assembly Machine needs 2 veteran operators work at the same time, with proficient welding skill.

D. Content of Product Family Z Series I H Beam Assembling and Tack Welding Machine:

This product introduction on Z series I H Beam Assembly and Tack Welding Machine, covers below topics of:

1) Standard models Z15, Z18, Z20 I H Beam Assembly Machine;

2) Special tailor made model Z30 I H Beam Assembling Machine;

3) 2 options of automatic and manual H Beam alignment style;

4) Automatic and manual CO2 tack welding 2 options;

5) Structure, working units, and function of I H Beam Assembly Machine;

6) Working mode, logic control, operation, service and maintenance of I H Beam Assembly and Tack Welding Machine;

7) Operation and put into use of I H Beam Assembling Machine;

8) CO2 welding power supply of I H Beam Assembling and Tack Welding Machine;

9) Advantage and business benefits of I H Beam Assembly Machine.

Customer can select proper model of conventional or tailor made Wuxi JACK I H Beam Assembling Machine, based on your request and condition.