A. The Composition, Application and Layout of Couple Working SXBJ-4 Automatic Steel Plate Edge Milling Machine:

1. Formation of the SXBJ-4 Couple Working Automatic Steel Plate Edge Beveling Machine:

1) Layout: There are 2 sets of SXBJ-4 automatic machine for steel plate beveling , which consist of this working group of 1st operation for steel plate edge grooving for welding preparation;

2) Each set of the SXBJ-4 automatic machine of steel plate edge milling has 2 sets of edge milling head and its moving carriage, with its edge milling angle managed with HMI (Human Machine Interface). In this respect, it belongs to a kind of advanced configuration Edge Milling Machine;

3) The function zone of Wuxi JACK SXBJ-4 automatic machine of steel plate edge milling: (Fig.1)

2. Application of the SXBJ-4 Couple Working Automatic Steel Plate Edge Groove Making Machine:

1) Where Used: This independent working group is applied in a large scale Port Machinery production line, at the starting point of the 1st operation operating zone;

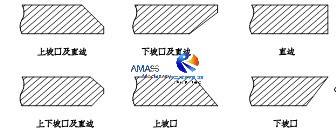

2) This Edge Milling Machine working group is for the purpose of making welding grooves at both sides of workpiece steel plates, completed in the form of both up, straight, and bottom edges of plates;

3) The design illustration on 6 types of common seen grooves made from XBJ and SXBJ series machine for steel plate edge milling: (Fig.2)

4) The working moment of Wuxi JACK coupling working SXBJ-4 automatic machine for steel plate beveling: (Fig.3)

3. Layout of the SXBJ-4 Couple Working Automatic Steel Plate Chamfering Machine:

1) The 2 sets of SXBJ-4 Automatic Steel Plate Chamfering Machine are installed in sequence, one following the other, in line with material flow of the production line;

2) To maintain the same workpiece top surface height level as the entire production line, the 2 sets of SXBJ-4 Steel Plate Edge Milling Machine are installed in a dug pit, forming a relative independent working zone, shown as below:

3) Front view on Wuxi JACK Couple Working SXBJ-4 automatic machine for steel plate edge groove making: (Fig.4)

B. Operation on the Couple Working SXBJ-4 Automatic Steel Plate Edge Beveling Machine:

1. Working Style of the SXBJ-4 Automatic Steel Plate Edge Milling Machine:

1) Each of the SXBJ-4 machine of edge milling performs its own dedicated job of working as welding groove maker on one side of the workpiece steel plate;

2) The two sets of SXBJ-4 machine of edge milling operate in pair, completing on task of machining welding groove on one piece of workpiece steel plate in one pass flow. Which means, these two sets of SXBJ-4 automatic machine for steel plate edge beveling work in couple, for making welding groove on the 4 corners of workpiece steel plate, by means of the straightforward flowing of workpiece. This is how does the product name of “Couple Working Edge Milling Machine” originated;

Operating in the Wuxi JACK SXBJ-4 Couple Working automatic machine of steel plate edge beveling at customer site: (Fig.5)

3) After this working zone of this Edge Milling Machine for carrying out welding groove making on raw material steel plates, the next working area is submerged arc welding implemented by welding robots; And following that is RH series Edge Rounding Machine for trimming on edges of steel plates;

2. Arrangement of the Couple Working SXBJ-4 Automatic Steel Plate Edge Milling Machine:

1) The on site deployment of the two sets of SXBJ-4 Automatic Steel Plate Chamfering Machine conforms to process flow technology of the production line, and task of the machine;

2) This steel plate edge milling executing unit in the two sets of edge milling carriages, which are installed on the two sets of SXBJ-4 Edge Milling Machine, are arranged at the interior and core area of the production line working zone;

3) In other words, the two sets of SXBJ-4 automatic machine for sheet metal steel plate edge beveling (Alias of Edge Milling Machine), are installed back to back along the working parts flow way of the Production Line;

4) Conveyors for sending in and transferring out workpiece from the two sets of machines for edge milling are arranged at incoming and outcoming side of the couple working zone;

5) There is a group of roller rocking arms between the two sets of Edge Milling Machine, where the two sets of edge milling carriages located, which act as manipulator of workpiece steel plate. Shown as below:

6) The roller rocking arm between the 2 sets of SXBJ-4 automatic machine for steel plate edge groove making : (Fig.6)

C. Technical Parameters of SXBJ-4 Couple Working Automatic Steel Plate Edge Milling Machine:

Model Technical Parameter | Couple Working SXBJ-4 Double Heads Automatic Steel Plate Edge Beveling Machine |

Steel Plate Edge Milling Max. Length | 4,000 mm by 2 Sets |

Steel Plate Edge Milling Max. Width | 3,000 mm by 2 Sets |

Quantity of Hydraulic Jacks for Clamping Workpiece Steel Plate | 7 Pieces / Set |

Milling Head Quantity | 2 Sets / Set |

Milling Angle Range of Up Milling Unit | 0° to +60°/ Set |

Milling Angle Range of Lower Milling Unit | -45° to 0°/ Set |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm / Set |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades adjusted by turning speed lever/ Set |

Hydraulic Power Motor | 5.5 kW / Set |

Milling Unit Feeding Motor | 2.2 kW / Set |

Plate thickness for Sheet Metal Chamfering | 6∼50 mm (Based on customer demand) / Set |

Edge Milling Speed | 130∼1000 mm/min. Continuously (VFD, Inverter Control)/ Set |

Idle High Speed of Edge Milling Head | 4000 mm/min. / Set |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200mm When make delivery) / Set |

Hydraulic Rated Pressure | 5.5 MPa / Set |

Hydraulic Working Pressure | 3.5 MPa / Set |

Hydraulic System Flowrate | 47 L/min. / Set |

Worktable Width | 450 mm / Set |

Worktable Height | 1050 mm / Set |