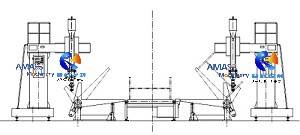

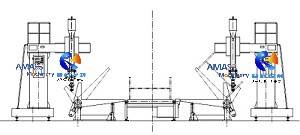

As you may find from attached photos, the H Beam Gantry Welding Machine here is equipped with red color U.S. Lincoln brand SAW power supply: (Fig.1)

1. SAW Power Supply in LHC Column H Beam Welding Machine:

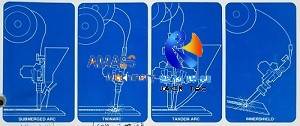

As introduced in the previous product of “45° Fillet Welding LHA Series H Beam Gantry Welding Machine”, for SAW power source being applied, another option we recommend is U.S. Lincoln DC-1000. It is the high end product of this type. There are six benefits with the Lincoln welding power source used in H Beam Welding Machine: (Fig.2)

1) Solid State Controls for Column H Beam SAW Welding Machine:

a) Precise management on welding process of T frame, gantry frame and Column I Beam Submerged Arc Welding Machine;

b) Striking characteristics, start and stop bead size and shape;

c) Arc stability in the whole SAW process of the I Beam Gantry Welding Machine;

d) Solid state circuits compensate for input voltage and electrode drag fluctuations, minimizing unexpected procedure changes during welding of the H Beam Welding Machine;

e) All these facilities economical welding to the most specific demands from customer;

2) High Productivity Promise for H Beam SAW Welding Machine:

a) Automatically deposits more metal at faster speeds, increasing output of (H Beam) I Beam Submerged Arc Welding Machine;

b) Current and voltage controls eliminate returning to the power source for routine procedure changes in H Beam SAW Welding Machine;

c) Integration control of power switch turning wire feeder input power on and off makes easy and convenient operation in H Beam Welding Machine;

3) Low Cost Repetitive Welds for H Beam Gantry Welding Machine:

a) Electrode position adjustments lock tight for pushbutton production welding with consistent quality;

b) Inch buttons feed electrode up and down when not in welding;

c) Start and Stop pushbuttons control welding and travel cycles of LHA gantry type, LHT T type, LHC column type H Beam Gantry Welding Machine;

d) Travel switch controls travel mechanism for automatic start and stop during welding, travel without welding during set up and travel off of the Column H Beam SAW Welding Machine;

4) General Purpose Operating mode for Column H Beam Welding Machine:

a) Wide range of processes, welding velocity, wire sizes, procedures and methods available and convert during operation of H Beam Welding Machine;

b) Cross seam adjuster lets operator of column H Beam Gantry Welding Machine easily track along irregular joints during welding;

c) High efficiency spur gear box results in a smaller head with no sacrifice on welding capability;

5) Easy Installation and Set Up for Operation of H Beam Gantry Welding Machine:

a) Compact power source size of superb flexibility fitting for complicated and sophisticated large Column H Beam SAW Welding Machine and H Beam production lines;

b) Simple head mounting with versatile positioning minimizes fixture requirements and speed set up;

c) Power source of the column type, T type and gantry type Column H Beam Welding Machine has cables up to 30m long for plug into control box;

6) Stable and Reliable Operation in Column H Beam SAW Welding Machine:

a) Solid state controls and rugged construction minimizes down time of the welding power source and maintenance costs of the Column H Beam Welding Machine;

b) Needs only regular service for long term usage of the LHT T style, LHC column style, and LHA gantry style I Beam Submerged Arc Welding Machine;

c) Plug in components can be quickly replaced for easy service of the H Beam SAW Welding Machine;

d) Function lights built into the printed circuit boards along with a comprehensive trouble shooting guide can speed up repair procedures of the H Beam Welding Machine;

7) Check below picture for Lincoln SAW power source used in gantry type, column type and T type Column H Beam Welding Machine: (Fig.3)

8) Same as HUAYUAN welding power source, when make shipment to customer on the Column H Beam SAW Welding Machine, the attached technical documents cover detailed manuals from Lincoln.

2. Technical Parameters of LHC Column H Beam Welding Machine:

Below are specifications of this LHC Column style H Beam Gantry Welding Machine:

LHC Column H Beam SAW Machine (I Beam Submerged Arc Welding Machine) |

Parameter | Specification | Note |

Operator Working Position | Stand on moving trolley of column body |

Fitting H Beam Flange Width (mm) | 200 ~ 800 |

|

Fitting H Beam Flange Thickness (mm) | 6 ~ 40 | Can be special made |

Fitting H Beam Web Height (mm) | 200 ~ 2000 |

|

Fitting H Beam Web Thickness (mm) | 6 ~ 32 | Can be special made |

Fitting H Beam Length (mm) | 4000 ~ 12000 | Can be special made |

Fitting Gantry Travel Rail Length (mm) | 15000 | Can be special made |

Submerged Arc Welding type | 45° fillet welding |

|

Submerged Arc Welding mode | Single Arc, Or Tandem Arc |

|

Welding Power Source brand and model | Chinese HUAYUAN or U.S.A Lincoln | ZD7-1000 or DC-1000 |

Welding Power Source quantity | 2 sets in the case of Single Arc, And 4 sets in the case of Tandem Arc | Machine quotation is different as in the case of Single Arc and Tandem Arc |