When Do Customer Need H Beam/ Plate Edge Rounding Machine?

A. Powerful Functions of Wuxi JACK H Beam / Plate Edge Deburring and Rounding Machine:

1. Usage and Purpose of End Plate Trimming Machine:

1) Function: Edge Rounding Machine trims edges of working parts into round angle of Φ2~ 2.5mm radius in high efficiency, by means of rounding rollers;

2) Working Velocity: The rounding speed can be up to 7000mm/min.;

3) Purpose: Edge rounding operation is for raising painting adhesion capability of workpieces, which will be used as assemblies in machineries working in wet environment;

2. Four Corners Simultaneously Being Trimmed in Edge Rounding Machine:

1) During operation, top and bottom edges at both sides of working parts can be rounded at the same time, in Wuxi JACK highly efficient End Plate Trimming Machine:

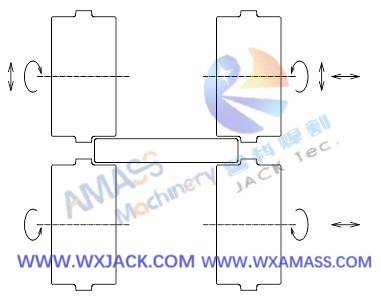

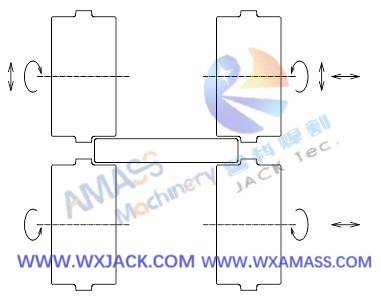

2) Working theory sketch on Wuxi JACK sheet metal steel plate Edge Deburring and Rounding Machine: (Fig.1)

3. Double Functions of Deburring and Trimming: In the running process, not only edges of working parts are grinded from sharp angles into round angles, but also these edges acquire good effect of being polished and deburred;

4. Applicable Workpieces of Edge Deburring and Rounding Machine:

Are not confined to:

1) Sheet metal steel plate: This accounts for majority of working parts;

2) Steel structure member H Beams are also available for being trimmed;

5. Working Sight of Wuxi JACK H Beam / Plate Edge Deburring and Rounding Machine:

1) Local close up view on working moment of Wuxi JACK RH2000 End Plate Trimming Machine: (Fig.2)

2) Flash moment of Wuxi JACK HR800 H Beam Edge Rounding Machine: (Fig.3)

B. Extensive Application Field of H Beam / Plate Edge Deburring and Rounding Machine:

1. Suitable Industries: H Beam/ Plate Edge Rounding Machine is the basic and requisite 1st operation equipment in the industries of: Shipbuilding/ Port Machinery/ Offshore Drilling Platform/ Steel Structure Construction, etc.;

2. Suitable Working Environment: The common point of these machineries is their high humidity working environment: Seaside or in the sea. So, everyday being eroded with sea water, the coating and painting surface of these machineries face great challenge on protection;

3. Necessity of H Beam and End Plate Trimming Machine:

1) By means of H Beam/ Plate Edge Rounding Machine, round angles of steel plates/ structure members can be raised on its painting adhesion performance;

2) So, next step of being manufactured into final machineries can be guaranteed on superior quality: Edge Rounding Machine helps maintaining the best degree of long term painting quality and durability of these machineries working in seaside surroundings;

4. Round corner of finished trimmed steel plate being delivered from Wuxi JACK RH1000 plate Edge Rounding Machine: (Fig.4)

5. Extended Advantages of H Beam/ Plate Edge Deburring and Rounding Machine:

1) Safer Logistics: Besides, round edges of H Beams/ steel plates are safer and more convenient for handling;

2) Better Appearance of finished machinery can be attained; This is another benefit brought along with introduction of H Beam/ sheet metal plate Edge Rounding Machine;

3) Extended to More Industries: Meanwhile, all the other machineries similar to Shipbuilding and Port Machinery, which work in surroundings with large amount of moisture, will see great benefit from H Beam / Plate Edge Deburring and Rounding Machine;

6. Summary Slides on RH series Edge Rounding Machine is illustrated in web page “Wuxi JACK Edge Deburring and Rounding Machine”.