A. Usage and Importance of SXBJ-12 General purpose Edge Milling Machine:

1. Wide Application of SXBJ-12 Double Heads Plate Beveling Machine:

1) The SXBJ-12 model is the most frequent selected and the largest selling model, in SXBJ series double milling heads Plate Edge Milling Machine;

2) It covers the largest share of customer demand on plate welding grooving, in terms of workpiece size, efficiency, and type of grooves produced;

2. Double Milling Heads Equipped in the Plate End Milling Machine:

1) For acquiring on 12,000mm length above edge milling stroke, due to its long motor drive moving stroke of milling heads, usually, it is more suitable to adopt 2 pieces of milling heads in one set of the machine, instead of only one milling head installed;

2) This is for the purpose of guaranteeing on machine high productivity;

3. Running Style of the Two Milling Heads in the Double Heads Plate Edge Milling Machine:

1) During running of the sheet metal plate End Milling Machine, the 2 sets of milling heads can work in couple, to make beveling on top and bottom edges of steel plate simultaneously;

2) Or work individually, to have plate edge milling process into different bevel type (For example, one milling head for cutting on straight edge, and the other milling head for milling on slant bevel) separately;

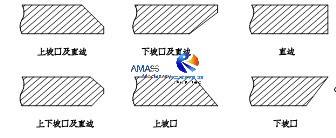

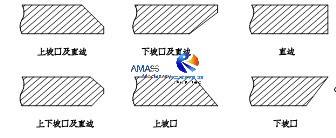

3) Types of welding grooves that can be edge milled in the machine: (Fig.1)

B. Technical Specialties and Strong Points of Wuxi JACK SXBJ-12 Sheet Metal Edge Milling Machine:

1. Hydraulic Drive Front Extension Workpiece Handling System in the Plate End Chamfering Equipment:

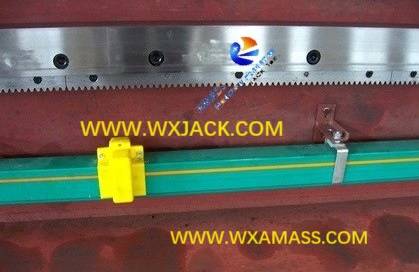

1) Same as product group of SXBJ-15 to SXBJ-18 large models machine, the hydraulic front extension (Please check the attached 2nd picture and below photo) of SXBJ-12 is very helpful for fulfilling large and heavy workpiece loading and unloading process:

2) It pushes workpiece of long and heavy metal plate forward before official edge milling operation, making sure safe and reliable handling of workpiece, relieving operators from dangerous/ tedious and hard job;

3) This is the unique feature of Wuxi JACK Plate Edge Milling Machine, and gained high recognition and welcome by customer since its introduction;

4) The hydraulic drive workpiece handling system equipped with Wuxi JACK Plate End Beveling Machine: (Fig.2)

2. Cable Slides in Wuxi JACK Plate End Milling Machine:

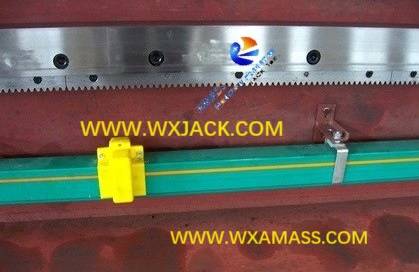

1) Considering the long distance of moving stroke, the 2 sets of milling units are electric powered by way of cable slides, which has advantage of compact size/ stable working and neat arrangement. Please see picture below:

2) Cable slides arrangement on along machine work table: (Fig.3)

3. Milling Carriage Horizontal Movement Guiderail Unit of Wuxi JACK Sheet Metal Edge Milling Machine:

1) Importance of such guiderail for Satisfactory Running of Plate End Beveling Machine:

a) During running period, horizontal movement of milling carriages is the most critical action: It fulfils edge milling operation;

b) For this reason, quality of such movement guiding rail is also of vital importance, which determines stability and precision of machine performance directly;

2) For Wuxi JACK SXBJ and XBJ series Plate Edge Milling Machine, guiderails of milling units horizontal movement comprise of 2 pieces which are horizontally installed in parallel;

3) The top guiding rail is equipped with HIWIN brand heavy duty precise linear railway along the complete length of machine mechanical bed, guaranteeing on accuracy of milling carriage running, and preventing dust from falling onto the rail at the same time;

4) The bottom guiding rail is rectangular cross section large size heavy duty guiderail, serving as supporting unit for movement of milling carriage in the machine, guaranteeing on stability of milling head movement. Please check below photo:

5) The double layers of milling carriages horizontal movement guiding rails in Wuxi JACK machine bed: (Fig.4)

4. The Dust and Debris Disposing Hopper in Wuxi JACK Plate End Milling Machine:

1) For effective guard on bottom rail, a piece of 2 stage dust scraping unit is installed on the milling unit, making sure the best degree of contamination control for machine operation. Please check below photo:

b) The double stage dust and debris collecting and disposing unit equipped in Wuxi JACK Plate End Beveling Machine: (Fig.5)

C. Technical Parameters of Wuxi JACK SXBJ-12 General purpose Edge Milling Machine:

Model Technical Parameter | SXBJ-12 Double Milling Head Plate End Beveling Machine |

Max. Plate Beveling Length | 12,000 mm |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Milling Head Quantity | 2 sets |

Plate thickness for Sheet Metal Chamfering | 6∼100 mm |

Milling Angle of Top Milling Unit | 0° to +80° |

Milling Angle of Down Milling Unit | -45° to +45° |

Edge Milling Speed | 130∼1000 mm/min. (VFD, Inverter Control) |

High Speed of Idle | 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200mm For delivery) |

Quantity of Hydraulic Jacks | 15 pieces |

Hydraulic Rated Pressure | 5.5 MPa |

Hydraulic Working Pressure | 3.5 MPa |

Hydraulic System Flowrate | 47 L/min. |

Worktable Width | 500 mm |