A. Origin and Application of 7 Axis 3000/9 Flame and Plasma Heavy duty CNC Pipe Intersection Cutting Machine:

1. The 7 Axis 3000/9 is derivatives product of 7 Axis 3000/12 Flame Plasma CNC Pipe Cutting Machine: The main difference between the two models is 3000mm shorter stroke along workpiece pipe length direction;

2. With the 7 Axis control in software and corresponding executing unit in hardware, together with fitting for the largest pipe diameter grade of up to Φ3000mm, this model 7 Axis 3000/9 is one of the Heavy duty CNC Pipe Intersection Cut Machine, in assorted products of CP series Flame Plasma CNC Pipe Intersection Cutting Machine;

3. Tailor made for Each Case of 7 Axis 3000mm Grade Heavy duty Flame Plasma CNC Pipe Intersection Cut Machine:

1) Commissioning Site of Wuxi JACK Exported to U.S.A 7 Axis 3000mm/9 Heavy duty CNC Pipe Cutting Machine at Customer Facility: (Fig.1)

2) For the complex control of 7 Axis, together with large pipe diameter of up to Φ3000mm, even with standard model of CNC-CP 3000-series, every set of the CNC Pipe Intersection Cutting Machine should be special designed and manufactured, as a turn-key package of solution for customer.

B. Ingenious Design in Mechanical System of 7 Axis 3000mm Grade Heavy duty Flame Plasma CNC Pipe Cutting Machine:

The V Axis and W Axis together with its Hardware in Heavy duty CNC Pipe Intersection Cutting Machine:

1. V Axis and W Axis are very useful for manipulating large diameter pipes cutting and beveling, which play important role in guaranteeing performance of Heavy duty CNC Pipe Intersection Cut Machine: This determines accurate position of cutting torch along radius direction of pipe;

2. For the wide range of pipe diameters, from as small as 23.62in (or 600mm) to as large as 3000mm (or 120inch), V Axis and W Axis of cutting torch along pipe radial direction should be precisely manipulated, during running of the large size CNC Pipe Intersection Cutting Machine;

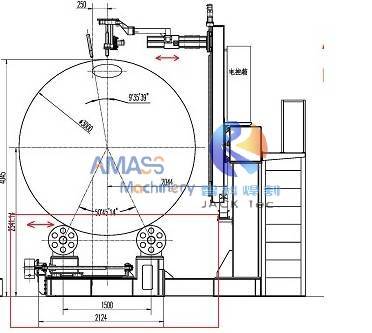

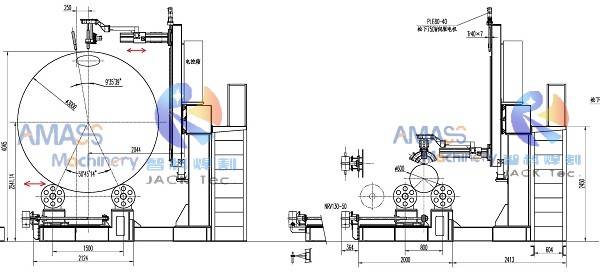

3. As to the corresponding hardware of mechanical structure to implement V Axis and W Axis management, in 7 Axis Flame Plasma CNC Pipe Cutting Machine, please check below diagram: (Fig.2)

1) As can be found from the above illustration, there are two units of turning rolls for supporting and rotating the workpiece pipe during work of the CNC Pipe Cutting Machine. These 2 groups of turning rolls have similar structure, and work in the similar logic as Welding Turning Roll;

2) The right set of turning rolls is fixed on the basement of the Heavy duty CNC Pipe Intersection Cutting Machine;

3) The other left set of turning rolls is installed on the movable beam, and is travelled integrally, catering for diversified range of pipe diameter;

4. Specification of V Axis and W Axis in 7 Axis 3000/9 Heavy duty CNC Pipe Intersection Cutting Machine:

1) For this specific model of 7 Axis 3000/9 Heavy duty CNC Pipe Cutting Machine, the max. span between the 2 sets of rolls is 1500mm, and min. span is 800mm;

2) Such span adjustment is for accommodating the extensive pipe diameter range of Φ600mm ~ Φ3000m;

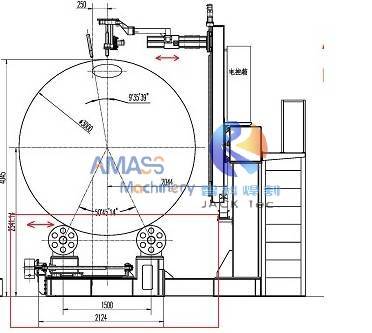

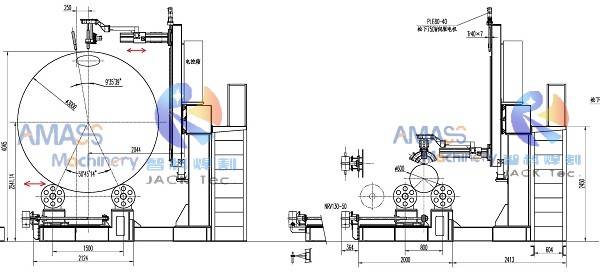

3) Please compare the variation of the section framed up, which is marked with red line, for the 7 Axis 3000mm CNC Pipe Intersection Cutting Machine, from left side of the diagram to right side, as blow: (Fig.3)

C. Technical Parameters of 7 Axis 3000/9 Heavy duty Flame Plasma CNC Pipe Cutting Machine:

Below is specification of 7-Axis 3000/9 Heavy Duty Flame Plasma CNC Pipe Intersection Cut machine:

Model Technical Parameter | 7 Axis CNC-CP 3000/9 Heavy duty Flame Plasma CNC Pipe Intersection Cutting Machine |

Suitable Diameter Range of Pipe For Cut and Beveling (mm) | 600 ~ 3000 |

Suitable Max. Length of Pipe for Cut and Beveling (mm) | 9000 |

Suitable Thickness of Pipe For Cut and Beveling (mm) | 6~100 mm for flame cutting 3 ~ 25mm for plasma cutting |

Suitable Cutting Speed For Cut and Beveling | 200∼800mm/min. for flame cutting Around 200~ 2000mm/min. for plasma cutting (Based on thickness of Pipe and Plasma Power) |

CNC Control Axis | 7 Axis of X/Y/Z/A/B/V/W X Axis: For pipe length cutting; Y Axis: For pipe rotation; Z Axis: For pipe diameter change; A Axis: For cutting torch swing along pipe radius; B Axis: For cutting torch swing along pipe length; V Axis: For cutting torch move along pipe radius; W Axis: For pipe holding turning rollers transverse move |