1. Outline on XBJ-9 Plate Edge Milling Machine:

1) Application Background: The attached photos record on working site of Wuxi JACK delivered XBJ-9 Plate End Milling Machine. This machine has wide application at customer side, under nearly all situations involving welding of metal plates;

2) It is a general purpose machine of 1st operation use, which has capability of various plate chamfering process. The longest metal plate that can be beveled in XBJ-9 is 9000mm.

2. Application of XBJ series Plate Edge Milling Machine:

1) What is Output of XBJ series Plate End Milling Machine?

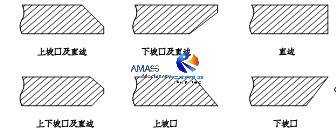

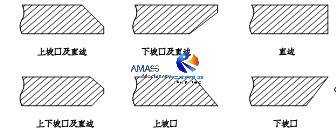

a) Bevels that can be milled on edges of sheet metal with the machine please check below sketch:(Fig.1)

b) XBJ series Plate Edge Milling Machine is a kind of advanced and highly efficient Plate Beveling Equipment for making welding groove, developed on the new process technology idea of “Edge milling substituting planning”;

c) The Edge Milling Machine can bevel various types of grooves on the edge of metal plate, especially steel plate: It is used for milling straight edge, slant edge U shape bevels and other kinds of required chamfers, serving as pre-machining equipment before welding;

d) Besides, circular arc shape groove can be machined when arc facer is installed;

The finished welding chamfers machined with the machine: (Fig.2)

e) The equipment that works need the support from this machine is MP series Plate Butt Joint Welding Machine;

2) What is Application Field of XBJ series Plate End Milling Machine?

a) This machine makes great contribution on improving product quality, boosting productivity, lessening energy consumption, and relieving labor intensity in the application field of steel plate welding and fabrication. In all summary, this is a progressive equipment for implementing sheet metal edge milling, taking the position of planning machine;

b) Application Field: XBJ series Edge Milling Machine of all models are widely applied in industries of Pressure Vessel, Boiler, Shipbuilding, Electricity Power, Chemical, Steel Structure, etc.

c) This machine can be either used as an individual working equipment, or applied in production line, such as H Beam Production Line, and BOX Beam Production Line;

3. Operation of XBJ series Plate Edge Milling Machine:

1) The XBJ-9 is equipped with a set of 7.5kW milling head with adjustable tilting angle, in the range of 0°~45°, which determines finished angle of welding groove;

2) Speed of plate chamfering can be adjusted with inverter control, and displayed on operating pendant of the Plate Beveling Machine, based on plate thickness and required bevel type;

3) Fixation of Workpiece in XBJ Series Plate Beveling Machine:

a) XBJ series machine is hydraulic drive for its workpiece clamping, during the plate chamfering process. Please check attached the second picture and below photo:

Hydraulic drive jacks pressing firmly steel plate, in the machine worktable: (Fig.3)

b) Before the sheet metal edge milling step, workpiece is sent into worktable of the machine by way of supporting extension racks at the front side of worktable, and fixed on the table with the array of hydraulic drive jacks, which are installed into bottom surface of pressing beam;

c) In XBJ series Edge Milling Machine, quantity of these hydraulic jacks is determined based on the max. valid edge milling stroke of the machine. For example, in XBJ-9 model, there are 15 pieces of hydraulic jacks distributed with the same interval;

4) The Two Critical Steps for Operation of XBJ series Plate Edge Milling Machine:

a) Before the process of sheet metal edge milling, two adjustment need to be made first:

b) Adjust tilting angle of the milling head, either by manual job, or with motor drive;

c) And modulating applicable plate chamfering speed, by means of turning the speed knob on operating pendant of the machine, which is actually controlled with A.C. inverter; At the completion of these steps, you can start official working of the Plate Edge Milling Machine.

4. Technical Parameters of XBJ-9 Plate Edge Mill Machine:

Model Technical Parameter | XBJ-9 Single Milling Head Plate Beveling Machine |

Max. Plate Beveling Length (mm) | 9000 |

Power of Milling Head | 7.5 kW |

Hydraulic Power Motor | 5.5 kW |

Milling Head Quantity | 1 set |

Quantity of Hydraulic Jacks | 15 pieces |

Plate thickness for Sheet Metal Chamfering | 6∼50 mm |

Edge Milling Speed | 130∼1000 mm/min. (VFD, Inverter Control) |

High Speed of Idle | 4000 mm/min. |

Hydraulic Rated Pressure | 5.5 MPa |

Hydraulic Working Pressure | 3.5 MPa |

Hydraulic System Flowrate | 47 L/min. |

Worktable Width | 450 mm |

Worktable Height | 1050 mm |