A. Usage, Specifications and Application of Sheet Metal Plate Butt Joint Welding Machine:

1. Function: MP series Plate Butt Joining Welding Machine is featured and superior product of Wuxi JACK company. This Flat Butt Welder is for completing on flat joining 2 pieces of steel plates, into an integral piece of longer or larger plate;

2. For Example: 2 pieces of 15m long steel plates to be butt joint along its longitudinal direction, in MP series Plate Flat Butt Welding Machine, to get a piece of 30m long steel plate:

A piece of 30m long integral steel plate being joint from 2 pieces of 15m long plates, in Wuxi JACK MP20 Sheet Metal Plate Joint Welding Machine: (Fig.1)

3. Workpieces Dimensions Suitable in Wuxi JACK MP Models Plate Flat Butt Welding Machine:

1) Plate Thickness for Butt Joint: MP series Plate Butt Joint Welding Machine is for fulfilling flat butt joint on metal plates with various thickness, especially carbon steel: From the minimum thickness of 1 ~ 6mm, to larger thickness of 6 ~ 40mm, or even thicker;

Finished flat joint steel plate acquired from Wuxi JACK Plate Butt Joining Welding Machine: (Fig.2)

2) Plate Width for Butt Joint: Max. width of sheet metal plates for butt joint in this Plate Flat Butt Welding Machine can be any size within the range of 2000 mm~ 5000 mm for conventional models, or specially designated specification of the Plate Flat Butt Welder by customer:

Wuxi JACK MP50 model Plate Butt Joint Welding Machine: (Fig.3)

4. Application of MP Series Sheet Metal Plate Butt Joining Welding Machine:

1) Task: MP series Plate Flat Butt Welding Machine is used for fulfilling flat butt joining on 2 pieces of metal plates (Material: carbon steel/ stainless steel/ Al) by means of butt welding;

2) The Related Products with this Plate Flat Butt Welder include: RH series Edge Rounding Machine, and J series Stiffener Plate Straightening Machine, which are used for manufacturing on large machinery;

3) Applied Industries: Together with MP series Plate Butt Joint Welding Machine, these machineries can be formed up various production line for Shipbuilding / Port Machinery, and Bridge Construction, Hoisting Machinery /Steel structure/ Tank Welding, etc., which have common points of large size steel plate being consumed as its raw material;

4) Besides, MP series Plate Flat Butt Welding Machine can also be applied as individual equipment of plate Flat Butt Welder under any special case.

B. Technical Superiority of Wuxi JACK MP Series Plate Flat Butt Welding Machine:

1. Patent Technology of Melt-Thru: In 2016 Wuxi JACK engineering team got the patent on core technology being applied in MP series Plate Butt Joining Welding Machine--- Melt Thru welding, which means: Single side welding and double sides welding seam formation:

Melt thru welding being carried out in Wuxi JACK MP series Plate Butt Joint Welding Machine: (Fig.4)

2. Welding Technique Adopted in Wuxi JACK MP Series Sheet Metal Plate Butt Joining Welding Machine:

1) Outline: MP series Plate Butt Joint Welding Machine is an efficient automatic running plate Flat Butt Welder, developed by our company on the basis of advanced technique, for butt joining on metal pieces of any size production;

2) Welding Modes Options on the Basis of Plate Thickness: The MP models Plate Joint Welding Machine can adopt welding technique of: Both GMAW CO2 welding for welding on thin plates, and SAW Submerged Arc Welding for welding on thick plates, with advantages of little deformation/ convenient and safe operation/ As well as good quality;

3. One Machine with Two Functions in Wuxi JACK Sheet Metal Plate Flat Butt Welder:

1) Plate Edge Milling Necessary: When plate thickness exceeds 15mm, to get full penetration of welding seam from the operation of melt-thru welding in the plate Flat Butt Welder, edge of plate need to be beveled before melt-thru welding;

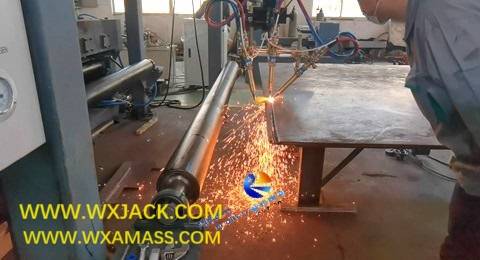

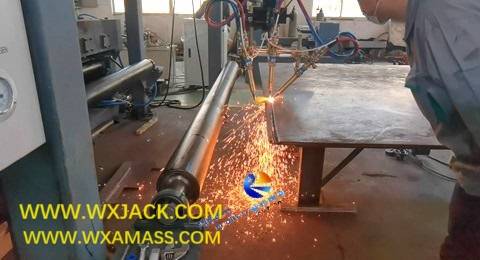

2) Beveling Way: This can be acquired either with XBJ series Edge Milling Machine or CNC-CG model Triple Flame Cutting Machine; Or, in MP series Plate Butt Joint Welding Machine, its plates coming in side can be equipped with triple flame cutting unit:

3) Triple flame cutting unit and running in Wuxi JACK Plate Butt Joint Welding Machine: (Fig.5)

C. Cost Saving and Production Efficiency Raise Benefitted from Wuxi JACK Flat Butt Welder Plate Joint Welding Machine:

1. Before Development of MP Series Sheet Metal Plate Flat Butt Welding Machine:

The 5 steps for metal plate joining process:

1) The 1st Step: Implement on welding one side of the 2 pieces of joint steel plates;

2) The 2nd Step: Flip the 2 pieces of half joint plates by means of traveling crane or other logistics equipment;

3) The 3rd Step: Carry out carbon arc gouging on the 2 pieces of half joint plates;

4) The 4th Step: Carry out welding on the opposing side of the 2 pieces of half joint plate;

5) The 5th Step: Carry out carbon arc gouging on the finished joint plates;

2. With Put Into Use of Wuxi JACK MP Models Plate Butt Joining Welding Machine:

1) Productivity Raise: Now, with advanced technique of Melt Thru (Single side welding and double side forming), by operating on MP series Plate Flat Butt Welding Machine, the 2nd to the 5th steps are removed, raising working efficiency on plate butt joint around 30%~40%;

2) Operator Reduced: The original necessary 2 operators for plate Flat Butt Welder can be reduced to only 1 operator now;

3) Safety Assurance: The safety risk of flipping heavy plates by means of traveling crane can be totally removed, guaranteeing fully operation of the plate Flat Butt Welder, benefiting from high level performance of Wuxi JACK MP series Plate Butt Joint Welding Machine.

D. Selecting Proper Models of Sheet Metal Plate Butt Joining Welding Machine:

1. Optional Welding Grooving Function Unit in Plate Joint Welding Machine:

a) Wuxi JACK MP series Plate Butt Joint Welding Machine has optional unit of triple flame cutting unit, for cutting out welding groove on edges of the joint plates, before melt thru welding in the Plate Flat Butt Welding Machine;

b) If customers do not choose this beveling unit in the plate Flat Butt Welder, the other option on making welding groove ahead of time can be:

1) XBJ series Edge Milling Machine;

2) CNC-CG series Triple Flame Cutting Machine;

2. Conventional Models of MP Series Plate Flat Butt Welding Machine:

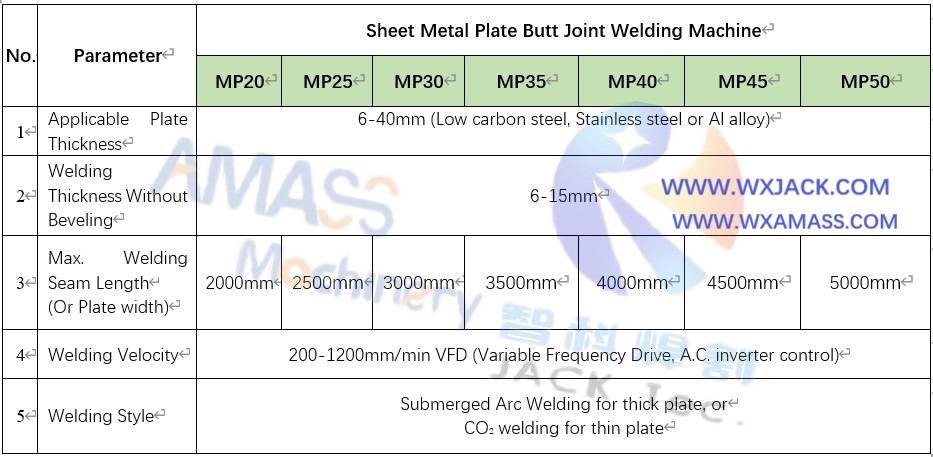

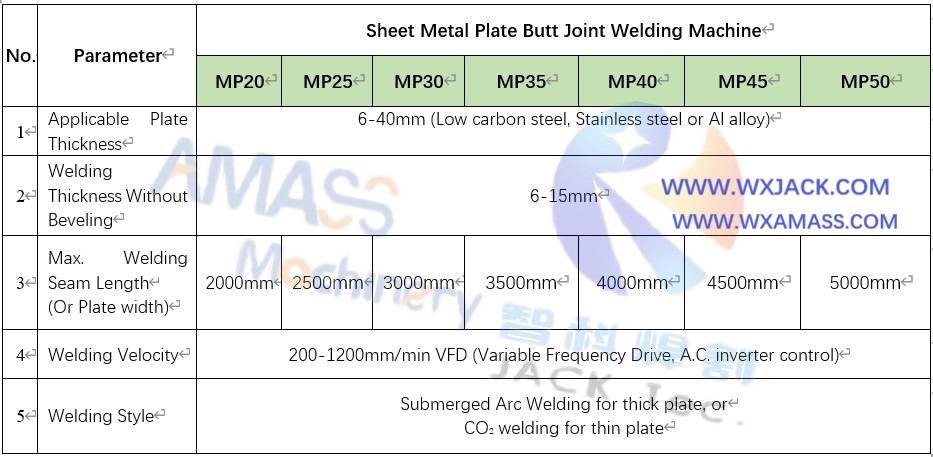

1) Based on the Max. plate width, which equals to the max. length of fabricated welding seam, there are several standard models of MP series Plate Butt Joint Welding Machine for customer selection, from MP20 to MP50 models plate Flat Butt Welder. The related technical parameters of the Plate Butt Joint Welding Machine are listed in below table;

2) Special Design: we can also design and produce special specifications of Plate Butt Joining Welding Machine, based on customer specific demands;

3. Summary on MP Series Plate Butt Joint Welding Machine:

1) Ever since MP series Plate Butt Joint Welding Machine was put into market, it gained more and more customer recognition and acceptance both in China and abroad, and sees rapid demand growth;

2) In the subsequent product sections of this MP series product family of plate Flat Butt Welder, we will have in depth exploration on technical features of MP models Plate Flat Butt Welding Machine from different aspects.

E. Technical Parameters of Wuxi JACK MP Series Plate Butt Joint Welding Machine:

Below are primary technical parameters of conventional models MP series Plate Flat Butt Welding Machine (Plate Flat Butt Welder):