HYJ series Mechanical H Beam Straightening Equipment has wide application in steel structure industry. The attached photos show its put into use at customer site, as well as production in batch at Wuxi JACK.

1. Scope of HYJ series Mechanical H Beam Straightening Machine:

1) This product refers to sub category of mechanical motor drive automatic models, including HYJ-40 and HYJ-800 standard model, as well as other custom made product;

2) In application of H Beam Flange Straightening Machine , HYJ series accounts for 60%~70% usage.

2. Usage of HYJ series Mechanical H Beam Straightening Machine:

1) Straightening Theory: HYJ series utilizes the theory of “Three points being stressed in a T shape cavity”, and uses A.C. motor as its driving force. The three pieces of straightening rollers are executing elements of the machine, to straighten the up bending deformed flanged of welding H Beam:

Cross section of H Beam: (Fig.1)

2) Wide Use: Nearly all the automatic H Beam Production Line adopts with HYJ series, either HYJ-40, or HYJ-800. The product can also work in semi-automatic H Beam production line, or as an individual equipment.

3. Straightening Principle of HYJ series Mechanical H Beam Straightening Machine:

Please check sketch as below: (Fig.1)

Straightening principle illustration and straightening rollers in H Beam Flange Straightening Machine: (Fig.2,3)

1) Shown from above, HYJ series motor drive has similar straightening process as medium duty hydraulic YTJ40 and YTJ-50 hydraulic drive models. For detail please check product introduction of Vertical Position YTJ40 Hydraulic;

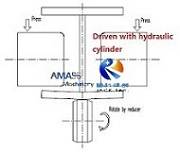

2) The only difference between HYJ series motor drive and YTJ series hydraulic drive is, driving power source on the two pieces of top straightening rollers is motor reducer, instead of hydraulic station by way of oil cylinder as in the case of YTJ series hydraulic drive models:

Straightening Energy source: A.C. motors: (Fig.4)

4. Straightening Capacity of HYJ series Mechanical H Beam Flange Straightening Machine:

1) For HYJ series, its limit on straightening flange thickness for Q235 (Tensile strength 370~ 510MPa) is 40mm;

2) For 16Mn material, the straightening speed is 70% of same thickness of Q235-A.

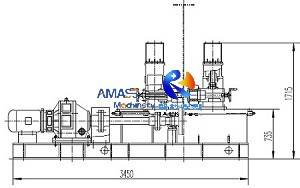

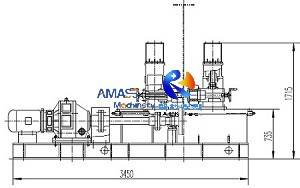

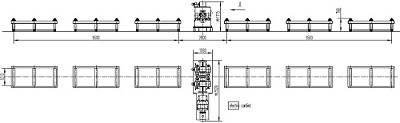

5. Machine Structure and Size of HYJ series Mechanical H Beam Straightening Machine:

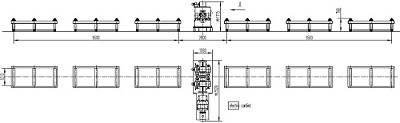

Sketch of main body and conveyor of HYJ series: (Fig.5,6)

1) Overall Dimension: Both HYJ-800 and HYJ-40 has overall machine size of around 3.5m L x 1.1m W x 1.7m H;

2) Standard configuration: 10m length input and output conveyor each. Customer can also prepare the conveyor by themselves, excluding it from supply range of the machine;

3) Total weight of HYJ800 is around 7~8 Ton;

4) Straightening Rollers of HYJ Mechanical H Beam Straightening Machine:

a) For workpiece (H Beam) straightened in HYJ-800, the allowable smallest web height is 350mm;

b) If web height is within the range of 160 ~300mm,and flange thickness≤14mm,assistant straightening roller will be used in the machine: One set of assistant straightening roller is prepared as delivery.

6. Operation of HYJ series Mechanical H Beam Straightening Machine:

1) Operating panel of HYJ series has similar operation as that of medium duty hydraulic drive YTJ-50 and YTJ-40 models. Please check below on panel of the machine exported to Russia:

Operating panel of H Beam Flange Straightening Machine: (Fig.7)

2) Difference between operating panel of HYJ series motor drive structure and YTJ series hydraulic drive is, HYJ series does not have control on hydraulic oil pump.

7. Technical Parameters of HYJ series Mechanical H Beam Straightening Machine:

PARAMETER | Specification | NOTE |

Model | HYJ-series Conventional Automatic Mechanical H Beam Flange Straightening Machine |

Straightening Power | Mechanical Motor Reducer |

H Beam Material | Q235 | Tensile strength 370~510MPa |

Flange Thickness (s) (mm) | 6 ~ 40 | Special made available |

Flange Width (b) (mm) | 200 ~ 800 |

Web Thickness (a) (mm) | ≤40 |

Web Height (h) (mm) | 200 ~ 1500 |

H Beam Length (mm) | 4000 ~ 12000 |

|

Straighten Speed (mm/min) | ≈9000/ 17000 |

|

Main Motor power (kW) | 7.5/ 22 |

|

Power Supply | 3P 380V for China | Can be made on country of customer |