A. Application of XBJ-15 Large Sheet Metal Edge Milling Machine:

1. The XBJ-15 is one of the common used specifications in product family;

2. Equipped with one set of 7.5kW milling head, this long stroke Large Plate Edge Milling Machine can have edge milling on metal plate with max. 15m length, and 50mm thickness.

B. Work Condition of XBJ-15 Large Plate Edge Beveling Machine:

1. The machine is kind of high precision machining equipment. To main the high standard delivery of this machine, there exist certain demand on its working environment;

2. The Corresponding Requirement on Working Environment of the Sheet Metal End Milling Machine can be Summarized as:

1) There should be free of explosive or corruptive gas, steam, rain water, chemical deposition that may harm normal operation of the general purpose Plate Edge Milling Machine;

2) Ambient temperature: -10℃~40℃

3) Relative humidity: Max. monthly average relative humidity is 90%

4) Power: Voltage fluctuation (for rated frequency) ≤±10%

5) Frequency fluctuation (for rated voltage): ≤±2%

3. The above listed demands are for the purpose of protection on milling head/ electric system/ hydraulic system, and mechanical frame of the XBJ series Edge Milling Machine.

C. Milling Head of Plate Edge Milling Machine and its Deliveries:

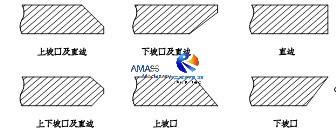

1. Delivery: Typical common seen standard welding grooves that can be made with the milling head of the machine: (Fig.1)

2. Source: Milling head driving facer blade is the central execution unit of the machine. It is the core outsourced unit, purchased by Wuxi JACK from professional supplier with long history and high standing reputation in the industry;

3. Pictures of the milling head adopted in the machine please check attached and below:

The 7.5kW milling head adopted in Wuxi JACK Sheet Metal End Milling Machine: (Fig.2)

4. Technical Features of Milling Head Equipped in Wuxi JACK Plate Edge Milling Machine:

1) For its spindle revolving speed, there are 6 grades to select, and made adjusted by means of easily turning the handwheels. Please check the photo as below:

The milling head with its 6 grades speed adjustment by lever, equipped in Wuxi JACK Plate Edge Beveling Machine: (Fig.3)

2) The Milling Head has 3 degrees of freedom during operation of Plate Beveling Machine:

The milling head unit and its 3 ways position adjustment in moving carriage of milling head: (Fig.4)

a) Up and Down: To adapt to varying thickness of the metal plate to be edge milled, this milling head can be elevated vertically under motor drive;

b) Feeding and Retreat: Its forward and backward of milling facer blade, which is installed on the front end of milling head, before official running, can be either pushed forward and pulled back by turning handwheel, or with motor drive;

c) Milling Angle Management: Adjust swing angle of the milling facer blade, which determines finished milling angle. This is one of critical technical index of Plate Edge Milling Machine. This also can be either manipulated manually, or with motor drive. It has metal dial ruler for indicating milling angle of milling head;

The high precision milling angle dial ruler equipped with milling head of Wuxi JACK Edge Milling Machine: (Fig.5)

3) In these ways, the milling head can have its position adjusted in comprehensive manner, getting the largest degree of freedom and flexibility, for the purpose producing the best quality of sheet metal grooving making.

D. Technical Parameters of XBJ-15 Multi-Purpose Single Milling Head Plate End Milling Machine:

XBJ-15 Large Sheet Metal Edge Milling Machine |

No. | Parameters | Value | Note |

1 | Max. Length of Plate Machined One Pass | 15000 mm |

|

2 | Plate Thickness | 6 ~ 50 mm | Can be special made |

3 | Milling Angle | Top Milling Unit | 0°∼+45° | 1 set of milling unit |

4 | Power and rpm of Milling Head | 7.5kW, 1440r/min |

|

5 | Diameter of Facer Blade | D=Ø125-Ø320mm | Ø200 Facer unit by default |

6 | Spindle rpm | 75-420r/min | 6 grades by hand wheel |

7 | Spindle Stroke | 100mm |

|

8 | Milling Speed | 150 ~ 1,000 mm/min | VFD |

9 | Milling Motor Power | 2.2kW | Inverter motor |

10 | Idle Speed | 4m/min. |

|

11 | Hydraulic Power | 5.5kW |

|

12 | Hydraulic Jack | 15 sets |

|

13 | Jack Screw | 25 sets | Intermittently installed |

14 | Workpiece Rack | 1 set |

|

15 | Machine Power System | 380V\50Hz\AC 3P | On customer demand |

|

|

|

|

|