A. Function and Application of SXBJ-18 Port Machinery Purpose Long Stroke Large Size Edge Milling Machine:

1. Application Site: This is a kind of typical double heads long stroke Edge Beveling Machine, which is purchased by a customer from Chinese Port Machinery Group. Considering the huge overall dimension of finished product of the facility, this SXBJ-18 model machine is installed and operated in open air working grounds;

2. Purpose: This SXBJ-18 model large machine is used for fulfilling high efficiently making welding grooves on edges of large size workpiece by means of its facer blade revolving cutting;

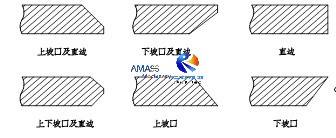

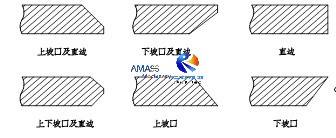

1) The list of bevels available for being machined from SXBJ-18: (Fig.1)

3. The Workpieces to be Processed in SXBJ-18 Long Stroke Large Size Edge Beveling Machine are:

1) Material is carbon steel plates, and length is from 500mm to 18,000mm;

2) Thickness of steel plate is from 6mm up to 100mm;

3) Width of steel plate is from 200mm to 3000 mm;

4) Correspondingly, the max. weight of carbon steel to be chamfered in this SXBJ-18 machine is: 18m length x 3m width x 0.1m thickness x 7.85 Ton/ cubic meter = 42.39 Ton, fairly big workpiece;

4. Put into Use on SXBJ-18 Long Stroke Large Size Edge Milling Machine:

Taking into account the application ground of this long stroke machine, the attached first photo and below vividly reflect its on site applicating features:

On site put into use of Wuxi JACK SXBJ-18 Long Stroke Large Size Edge Beveling Machine: (Fig.2)

1) Working Environment: Considering the large size and heavy weight of raw materials and finished product of Port Machinery, as well as easy handling of materials, this advanced configuration Large Edge Milling Machine is installed in outdoor open air;

2) Material Handling: There is hydraulic drive automatic steel plate loading system at the front side of the SXBJ-18, which is left side of the machine main frame in the photo. This is naturally conceivable, because, as introduced at the beginning of this product section, the workpieces for SXBJ-18 are really huge and heavy, which should be pushed by means of automatic rolling rollers, instead of manual job;

3) Material Pressing: During operation of SXBJ-18, its large and heavy workpieces steel plate is pressed firmly by means of array of hydraulic drive jacks installed in the machine, which is shown in the right side of photo. The specific quantity of these hydraulic jacks is determined based on model, or nominal edge milling stroke of the XBJ series Edge Milling Machine.

B. Technical Specifications of the SXBJ-18 Long Stroke Large Edge Milling Machine:

1. During Initial Discussion on the SXBJ-18 Large Size Edge Beveling Machine:

This is what customer expected on its performance:

1) Processing of edges for steel plates fabrication assistance;

2) Finished V chamfer angle is in the scope of 25° ~ 60°, blunt to 2.0 mm;

The V chamfer on edge of carbon steel plate, cut from the SXBJ-18 Large Edge Chamfering Machine: (Fig.3)

3) Finished X chamfer angle is in the scope of 25° ~ 60°, blunt to 2.0 mm;

The X chamfer produced from the SXBJ-18: (Fig.4)

4) Beveled chamfer f (bevel width is in the range of 15-80 mm, blunt to 4.0 mm);

5) Straightness of the milled edge should be kept within the tolerance of ± 0.2mm, roughness of finished beveled 12.5 £ Ra < 25;

2. Provide for the possibility of performing on straight edge milling and chamfering in one pass along the machine work table stroke of the workpiece;

3. Milling on the short end edge of the working part 3000 x 18000 mm should be provided in the large size Edge Milling Machine;

4. The SXBJ-18 large size Edge Beveling Machine should include a system of automated positioning of the workpiece before edge milling, which refers to feeding roller or cross conveyor with stops;

The hydraulic oil cylinder driving automatic positioning system for workpieces in SXBJ-18 (Fig.5)

5. Mechanical Main Frame of SXBJ-18 Long Stroke Large Size Edge Milling Machine:

1) Requirement on mechanical frame of this large machine is its strength/ rigidity/ levelness along the entire length;

2) This is the basis for guaranteeing on stability and consistency of heavy force edge milling operation, along the entire length of the SXBJ-18 large machine;

3) Mechanical main body of SXBJ-18: (Fig.6)

4) As can be checked from the above photo, the double stages precise linear guiderail for guiding on movement of milling head, together with its transmission rack, are assembled onto top/ bottom, and middle level of the machine mechanical bed respectively.

C. Technical Parameters of SXBJ-18 Port Machinery Purpose Long Stroke Large Size Edge Milling Machine:

Model Technical Parameter | SXBJ-18 Double Heads Long Stroke Large Size Edge Beveling Machine |

Steel Plate Edge Milling Length Range | 500mm ~ 18000 mm |

Steel Plate Edge Milling Width Range | 200mm ~ 3000 mm |

Plate Thickness for Sheet Metal Chamfering | 6∼100 mm |

Power and rpm of Milling Head | 11 kW, 1440 rpm |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Quantity of Hydraulic Pressing Jacks | 30 Pieces |

Hydraulic Power Motor | 5.5 kW |

Milling Head Quantity | 2 sets |

Edge Milling Speed | 130∼1000 mm/min. (VFD, A.C. Inverter Control) |

High Speed of Idle | 4000 mm/min. |

Hydraulic Rated Pressure | 5.5 MPa |

Hydraulic Working Pressure | 3.5 MPa |

Hydraulic System Flowrate | 47 L/min. |

Worktable Width | 550 mm |

Worktable Height | 1050 mm |