A. Outline on SXBJ-16 Outdoors Operation Large Plate Edge Milling Machine:

1. Working Site: As can be observed from attached photos, this is a set of heavy duty large size Sheet Metal Edge Beveling Machine installed and operated outdoors, for milling on welding grooves on long length steel plate;

2. Machine Protection: Due to its working environment of outdoors, this large scale equipment should be treated with special care, to effectively protect it from invasion of wind and rain;

3. The Workpieces Applicable for SXBJ-16 Large Plate End Milling Machine:

1) Length of metal plate is up to 16000mm;

2) Thickness of metal plate is in the range of 6~ 80mm;

3) Material of workpiece sheet metal is majority carbon steel plate;

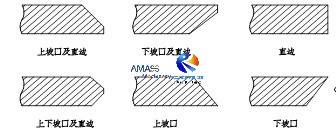

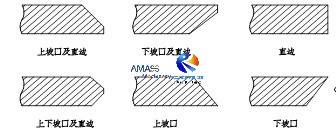

4) Welding grooves that can be beveled with this equipment: (Fig.1)

5) Finished beveled steel plate machined from outdoors running Wuxi JACK SXBJ-16 model machine: (Fig.2)

4. In a nutshell, this set of SXBJ-16 long stroke double heads large Plate Beveling Machine is applied in a Shipbuilding facility.

B. Structure of SXBJ-16 Outdoors Running Large Sheet Metal Edge Beveling Machine:

1. Machine Constructure: As can be checked from attached photos, the XBJ series Sheet Metal Edge Milling Machine has the integral constructure of stationary gantry beam;

2. At its front side, there is equipped with loading and unloading unit of manual push and or hydraulic drive front extension racks, for the purpose of workpiece handling into and out of the machine;

3. Edge milling working units are installed at back side of the machine, for performing on edge milling operation.

C. Main Units of the SXBJ-16 Large Plate Edge Milling Equipment:

1. Mechanical System of the Edge Milling Machine:

This is the main body of the machine. It includes:

1) Mechanical base bed, with working table assembled on its top side;

Mechanical base bed of the machine: (Fig.3)

2) Gantry style pressing beam. Gantry structure is assembled with working table into an integral mechanical body of the machine;

Assembling base bed working table and pressing beam into mechanical structure of Edge Beveling Machine at customer site: (Fig.4)

3) Manual or hydraulic drive front extension unit at the front of machine, for the tasks of plate feeding and unloading;

4) 2 sets of moving carriages of Milling head. During operation period, these moving carriages move along mechanical work table in edge milling working speed;

Fitting up 2 sets of milling carriages onto the Wuxi JACK double heads Edge Milling Machine: (Fig.5)

5) Top and bottom double layers guiderails for guiding movement of milling carriage along machine work table: (Fig.6)

6) 2 sets of 7.5 kW milling head with adjustable milling angle (by hand turning, or by motor drive denoted by customer) and continuously adjustable working speed (A.C. Inverter control);

Milling head with its angle adjustment in Large Plate Edge Milling Machine: (Fig.7)

7) Auxiliary unit, such as security fender, plate feeding fender, etc.;

Steel Plate Fender Unit in working table of machine: (Fig.8)

2. Hydraulic System of the Plate Edge Beveling Machine:

1) This is “energy source” of the Plate Edge Milling Machine. It drives group of jacks for holding down workpiece firmly during edge milling steel plate process. Please check the attached 4th photo;

2) Management and operation of the hydraulic system are individual, not integrated with the control system of the machine;

3) There is a panel on the hydraulic pump station. And the pump station is put alongside with the machine main body;

3. Electric Control System of the Plate End Milling Machine:

1) Core electric control unit of machine is A.C. inverter, together with control relays and contactors;

2) Control board is fit on the motorized carriage of milling head, and moved along with the carriage during machine operation;

3) A hand held operating pendant is put alongside the moving plate edge milling unit, for the purpose of fulfilling easy and convenient operation.

D. Technical Parameters of SXBJ-16 Outdoors Running Large Plate Edge Milling Machine:

Model Technical Parameter | SXBJ-16 Double Milling Heads Sheet Metal Edge Milling Machine |

Max. Plate Edge Milling Length (mm) | 16,000 |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Milling Head Quantity | 2 sets |

Plate Thickness for Sheet Metal Chamfering | 6∼80 mm |

Milling Angle of Top Milling unit | 0° to +80° |

Milling Angle of Down Milling unit | -45° to 45° |

Edge Milling Speed | 130∼1000 mm/min. (VFD, Inverter Control) |

High Speed of Idle | 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200mm For delivery) |

Quantity of Hydraulic Jacks | 19 pieces |

Hydraulic Rated Pressure | 5.5 MPa |

Hydraulic Working Pressure | 3.5 MPa |

Hydraulic System Flowrate | 47 L/min. |

Worktable Width | 450 mm |