A. The Usage and Background of CP3-1000/15 Automatic Flame CNC Pipe Cutting Machine:

1. Usage of Automatic CNC Pipe Intersection Cutting Machine:

1) This is a special model in CP series Automatic CNC Pipe Intersection Cutting Machine, for producing cut and beveled pipes with diameter up to Φ1000mm, and length up to 15m;

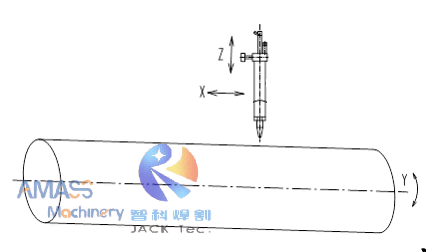

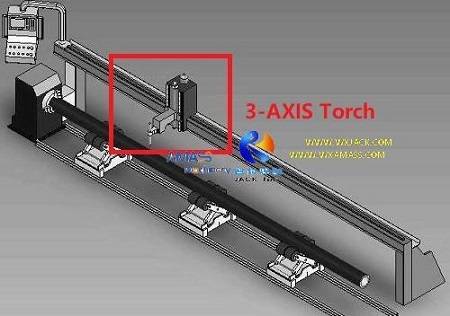

2) With the 3 Axis control (X/Y/Z axis), this Automatic CNC Pipe Cut Equipment can cut out holes in pipes, or cut off designated length of pipe;

3) The 3 Axis in Automatic CNC Pipe Intersect Cutting Machine: (Fig.1)

2. Background: Some customers have their workpiece in the style of thin wall pipes, which does not need to have slant edge beveling ang groove. The 3 Axis Automatic CNC Pipe Cutting Machine is a good choice:

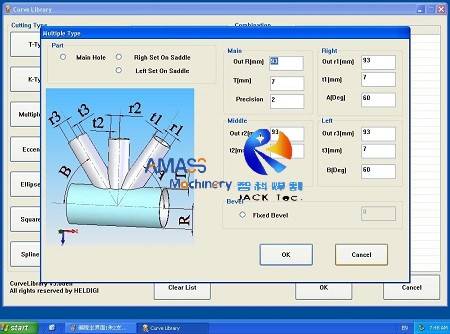

The Cut Out Workpieces from 3 Axis Automatic CNC Pipe Cut Equipment: (Fig.2)

B. Technical Features of CP3-1000/15 Automatic CNC Pipe Intersection Cutting Machine:

CP3-1000/15 was developed on the basis of CP3/600 series and CP3/1400 series Automatic CNC Pipe Cutting Machine. With diameter fit between that of the two models, this model of CP3-1000/15 has its technical features overlapped with the two models of CNC Pipe Cutting Machine also:

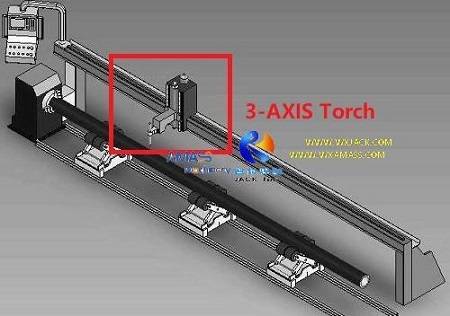

The attached first photo and below photo gives working moment of Wuxi JACK CP3-1000/15 Automatic Flame CNC Pipe Cutting Machine: (Fig.3)

From the photos we can see that:

Cutting Media: The Automatic CNC Pipe Cutting Machine uses Oxy-fuel flame cutting as its cutting method. This is the mainstream in the field of pipe cutting, which has advantages of reliability, cost effectiveness and easy maintenance;

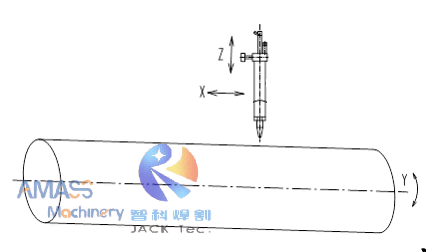

Cutting Torch: Compared with 5 Axis/6 Axis/7 Axis CNC Pipe Intersection Cutting Machine, cutting torch in 3 Axis CNC Pipe Cutting Machine has much more simple and concise mechanism, removing the element for swiveling and tilting: (Fig.4)

3. Workpiece Support in CP3-1000/15 Automatic CNC Pipe Cutting Machine:

1) Φ600mm is the up limit for necessity of chuck claw fixture. Beyond that, larger pipes in CNC Pipe Cutting Machine do not need dedicated fixture to lessening its momentum;

2) Friction roller support in CP3-1000/15 Automatic CNC Pipe Intersect Cutting Machine: (Fig.5)

3) Compared with chuck claw type for small pipes, the friction roller holding and revolving unit has advantages of easy handling, which will reduce non-value added time of Automatic CNC Pipe Cutting Machine running.

C. Adaptability of CP3-1000/15 Automatic Flame CNC Pipe Cutting Machine:

Convenience is one of important factors to consider during development of the Automatic CNC Pipe Intersect Cutting Machine. Especially in recent years, with more and more Automatic CNC Pipe Cut Equipment not only applied in China, but also exported to overseas market, Wuxi JACK have many measures taken to make the CNC Pipe Cutting Machine adaptable for use internationally:

1. Multilingual of Human Machine Interface in Automatic CNC Pipe Intersection Cutting Machine:

CNC of this Automatic CNC Pipe Cutting Machine covers all the main languages in the world, including Chinese, English, Russian, etc.;

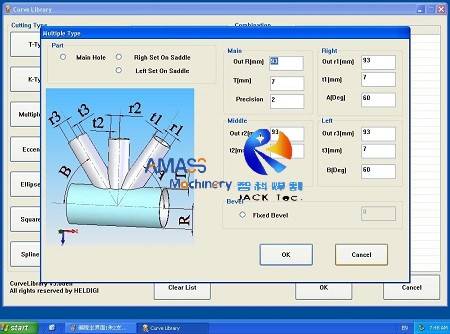

English Interface in CNC of Wuxi JACK Automatic CNC Pipe Cutting Machine: (Fig.6)

2. Flexible Power of Automatic CNC Pipe Cutting Machine Catering for Different specifications around the World:

For example, we make 480V/ 60Hz/3P for U.S.A customers, and 415V/ 50Hz/3P for India;

3. Transition between Metric System and Inching System in Running of the CNC Pipe Intersect Cutting Machine:

To accommodate using habit of customers of different countries, with metric system data at background of CNC in CNC Pipe Cutting Machine, the data present on CNC screen is in inching system when customers choose it;

D. Technical Parameters of CP3-1000/15 Automatic Flame CNC Pipe Cutting Machine:

Below is specification of CP3-1000/15 Automatic CNC Pipe Intersect Cutting Machine:

Model Technical Parameter | 3 Axis CNC-CP 1000/15 Automatic CNC Pipe Intersection Cutting Machine |

Applicable Diameter Range of Pipe (mm) | 300 ~ 1000 |

Applicable Max. Length of Pipe (mm) | 15,000 |

Applicable Thickness of Pipe (mm) | 6~100 mm |

Applicable Cutting Speed | 200∼800mm/min. controlled with CNC |

Effective CNC Control Axis | 3 Axis of X/Y/Z X Axis: Along pipe length direction; Y Axis: Pipe rotation; Z: Along vertical direction |