A. Usage of HB Series Welded H Beam Production Line:

1. Function of and Finished Workpieces:

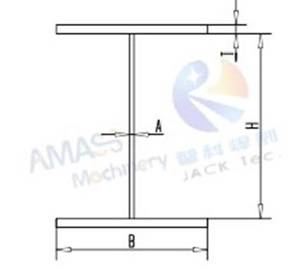

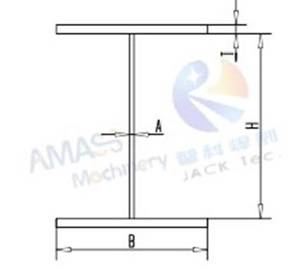

This machine group is for producing welded H Beam (I Beam)/ T Beam with specifications of: (Fig.1)

1) Web Height H: 150mm ~ 1,500/ 1,800/ 2,000mm;

2) Web Thickness A: 6mm ~ 32mm;

3) Flange Width B: 200mm ~ 800mm;

4) Flange Thickness T: 6mm ~ 40mm;

Welded H Beam produced from Wuxi JACK Welded H Beam Production Line: (Fig.2)

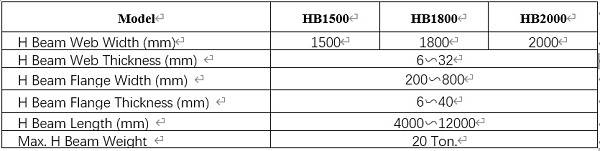

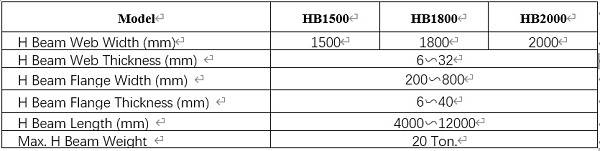

2. Models of Welded H Beam Production Line:

Is on the basis of the Max. web height of produced H Beam:

1) HB1500: Max. H Beam web height is 1500mm;

2) HB1800: Max. H Beam web height is 1800mm;

3) HB2000: Max. H Beam web height is 2000mm;

4) General specifications of H Beam fabricated: (Fig.3)

3. Wide Application: HB series Welding H Beam Production Line with SAW welding system is the most extensive used machine group in Steel Structure Industry. It is the indispensable machine complex to be applied at all the facilities on constructing steel structure:

Wuxi JACK HB1500 Welded H Beam Production Line works at customer site: (Fig.4)

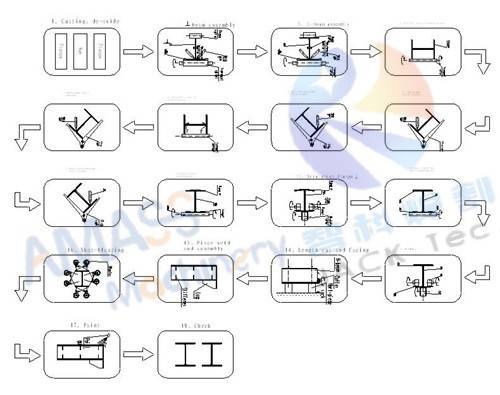

B. Major Steps and Related Equipment in HB Series Welded H Beam Production Line:

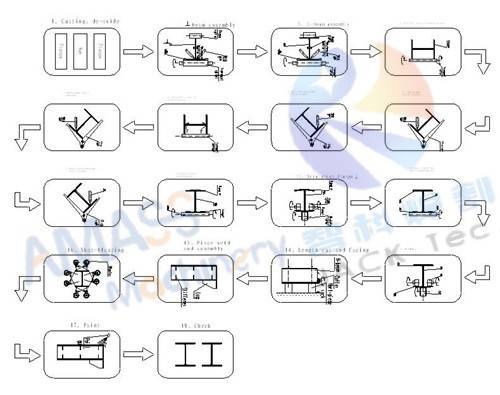

Process Technology for producing welded H Beam: (Fig.5)

1. Step One: Plate Cutting:

With CNC-CG4000 CNC Strip Plate Cutting Machine:

1) Task: This step is for cutting carbon steel plate into strip plates, which will be used as flanges and web, in the subsequent steps of H Beam assembly and stitch welding/ SAW welding and straightening:

2) Wuxi JACK CNC Strip Plate Cutting Machine and cut off strip plates: (Fig.6)

2. Step Two: H Beam Fitting Up and Tack Welding with Welded H Beam Assembly Machine:

1) Task: This step is the first crucial work station at Welded H Beam Production Line:

2) T Beam Assembly: First one piece of flange and one piece of web are assembled into T Beam, and strengthened with CO2 tack welding at the same time;

3) H Beam Assembly: Then, the T Beam is flipped 180°. The 2nd piece of flange is loaded into H Beam Assembly Machine. And the T Beam is assembled and tack welded into H Beam:

4) Wuxi JACK Z20 model H Beam Assembly Machine works at steel structure customer workshop: (Fig.7)

3. Step Three: H Beam SAW (Submerged Arc Welding) with Welded H Beam Welding Machine:

1) Task: This is the central working zone of Welded H Beam Production Line. The assembled H Beam will be performed with 45° fillet SAW welding;

2) Welding Frequency: There are 4 passes of welding seam in one piece of H Beam. Consequently, there are 2 options of H Beam Welding Machine for customer choice:

a) Automatic Line: 4 sets of Wuxi JACK LHC model column structure H Beam Welding Machine, runs at export to East Europe fully automatic H Beam Production Line: (Fig.8)

b) Semi-automatic Line: 1 set of Wuxi JACK LHA or LHT model gantry frame H Beam Welding Machine: (Fig.9)

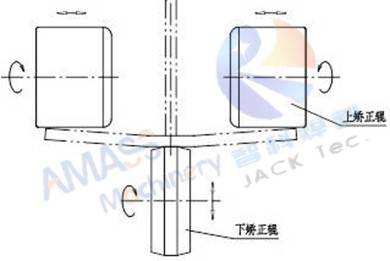

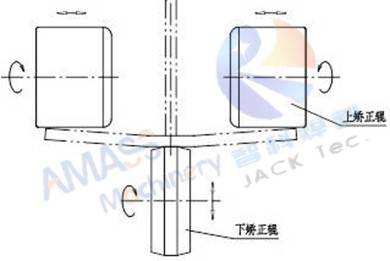

4. Step Four: H Beam Flange Straightening with Welded H Beam Straightening Machine:

1) Why Need: Flange of H Beam has upward bend deformation after SAW welding, because of heat input. H Beam Straightening Machine is for flattening such deformation:

2) Working theory indication on H Beam Straightening Machine: (Fig.10)

3) Major Types of Wuxi JACK H Beam Straightening Machine:

Based on: Tensile strength/ thickness/ deformation position of H Beam flange, there are 3 major types of:

(1) Straightening force motor drive, for light to medium duty H Beam;

(2) Straightening force hydraulic oil cylinder drive, for heavy duty H Beam;

(3) Longitudinal deflection H Beam:

(1) Wuxi JACK HYJ800 motor drive H Beam Straightening Machine, for straightening H Beam with material Q235 carbon steel up to 40mm thickness: (Fig.11)

(2) Wuxi JACK YTJ80 hydraulic H Beam Straightening Machine, for straightening H Beam with material Q345 carbon steel up to 80mm thickness: (Fig.12)

(3) Wuxi JACK HJ300 longitudinal H Beam Straightening Machine, for straightening steel structure workpieces along horizontal body: (Fig.13)

5. Step Five: H Beam End Face Milling with H Beam End Face Milling Machine:

1) Task: This step is EOL (End of line) work station of welded H Beam Production Line. It polishes end faces of fabricated H Beam/ T Beam, removing burr and dirt, making end faces of workpieces gloss and clean:

2) Wuxi JACK DX1520 H Beam End Face Milling Machine works at steel structure facility: (Fig.14)

6. Material Transfer: The WIP (Work in process) working parts transfer among all the above work stations of welded H Beam Production Line, is implemented with Welded H Beam Turntable Machine.