A. The Unique Function and Configuration of SXBJ-12 Large Plate Edge Milling Machine:

1. Exceeding than Conventional SXBJ-12 Plate Edge Beveling Machine:

1) Uniqueness: Unlike conventional models machine, this set of machine makes groove on both sides of metal plate simultaneously, this is what distinguishes this model of Sheet Metal End Milling Machine from others:

2) Structure: Correspondingly, the two sets of 7.5kW milling head are installed at both sides of the machine mechanical working table, as shown in below figure:

3) The 2 sets of milling head installed and working at both sides of SXBJ-12: (Fig.1)

2. Workpieces Applicable for SXBJ-12 Double Acting Sheet Metal End Milling Machine:

1) Besides conventional working manner of single piece of steel plate being beveled in the machine,

2) The unique workpieces that available being grooved are narrow long steel plate for both sides edge milling;

3) Or 2 pieces of strip plated put together, being grooved at the same time, shown in below:

4) The workpieces steel plate being beveled in this special design double acting SXBJ-12 Sheet Metal Edge Grooving Machine: (Fig.2)

5) Workpiece Size Range: When making sides edge milling, the width of steel plate clamped in the machine ranges from 300mm to 1000 mm;

3. Configuration of SXBJ-12 Double Sides Working Large Plate Edge Milling Machine:

1) Other main units of this special made machine are same as conventional models;

2) Mechanical Structure of Plate Edge Milling Machine:

The distinction of this double acting large model lies at its mechanical structure. Please compare below 2 photos:

a) The mechanical machine bed of conventional model Edge Milling Machine: (Fig.3)

b) The mechanical machine bed of double side acting Sheet Metal End Milling Machine: (Fig.4)

3) This is because, in this double side acting machine, both sides of mechanical machine bed should be installed with milling head and its moving carriage.

B. Purpose of XBJ and SXBJ series Plate Edge Milling Machine:

1. This is a kind of prevailing and popular Plate Edge Grooving Machine, for milling on welding preparation on metal plates before welding;

2. Welding Grooves Cut from the Plate Edge Milling Machine:

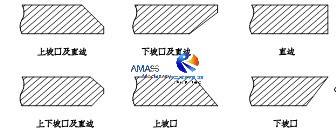

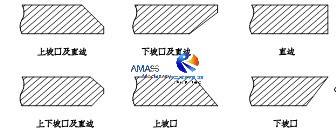

There are series of various grooves that can be beveled in this machine , shown as below:

1) The typical bevels that can be grooved in XBJ series Edge Milling Machine: (Fig.5)

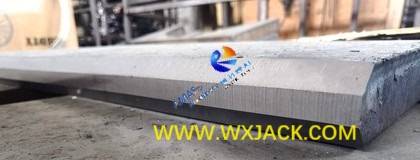

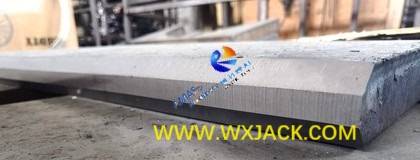

2) The finished grooved steel plate produced from Wuxi JACK Plate Edge Beveling Machine: (Fig.6)

3. XBJ series Sheet Metal Edge Milling Machine is the main stream of machines for cutting out welding grooves on sheet metal with high efficiency and performance. The other 2 kinds of equipment which have similar functions are: CG series Triple Flame Plate Cutting Machine, and GD series Hobbing Cutter Shearing Machine.

C. Structure and Main Units of XBJ series Sheet Metal Edge Milling Machine:

1. Structure and Sub Group of Plate Edge Beveling Machine:

1) As can be observed from attached picture, the XBJ and SXBJ series single head and double heads sheet metal Plate Edge Milling Machine has gantry body structure;

2) Length of Sheet Metal End Milling Machine Working Table is determined by below factors:

a) Required valid length of metal plate being grooved and beveled in the machine;

b) As well as quantity of milling head denoted in one set of the machine: Usually 1 set, 2 sets, 4 sets;

c) Correspondingly, models of the machine are XBJ, SXBJ, and FXBJ respectively;

2. Main units of Plate Edge Milling Machine:

Main units of XBJ series machine cover:

1) Mechanical system, including the machine mechanical main frame, workpiece supporting and loading rack;

2) Hydraulic power system, including pump station, electromagnetic valve, oil pipeline;

3) Electric control system of electric components, cables;

4) Machine tool of milling head, and its traveling carriage;

3. This SXBJ-12 double sides acting machine has the same structure as that of the remaining models and design of its product group. The major difference lies in max. valid plate edge milling length of 12m.

D. Quality Control in XBJ series Plate End Milling Machine:

1. As a leading company in Welding Machinery and Cutting Machinery Industry, Wuxi JACK has strict and comprehensive production and quality management system, across the entire value chain throughout order to delivery of the XBJ and SXBJ series machine;

2. This involves below critical steps during developing and manufacture of Plate Edge Beveling Machine:

1) IQA (Incoming Quality Assurance), on all the outsourced components of machine, including milling head, hydraulic pump, control elements, etc. are all renowned brands of best quality in industry;

2) Internal Process Quality, and Customer service, making sure top level machines of all specifications delivered to customers in committed lead time.

E. Technical Parameters of Double Sides Grooving SXBJ-12 Large Plate Edge Milling Machine:

Model Technical Parameter | SXBJ-12 Double Milling Heads Double Sides Acting Sheet Metal Edge Milling Machine |

Max. Plate Beveling and Grooving Length | 12000 mm |

Power of Milling Head | 7.5 kW |

Hydraulic Power Motor | 5.5 kW |

Milling Head Quantity | 2 sets |

Plate thickness for Sheet Metal chamfering | 6∼50 mm |

Workpiece Width Scope for Both Sides Grooving | 300 ~ 1000 mm |

Quantity of Hydraulic JACKs | 20 pieces |

Edge Milling Speed | 130∼1000 mm/min. (Variable Frequency Drive, Inverter Control) |

High Speed of Idle | 4000 mm/min. |

Hydraulic Rated Pressure | 5.5 MPa |

Hydraulic Working Pressure | 3.5 MPa |

Hydraulic System Flowrate | 47 L/min. |

Worktable Width | 550 mm |

Worktable Height | 1050 mm |