1. The Importance and Benefit of Welding Seam Tracker Equipped in Welding Manipulator:

1) Important Supplementary Function Unit: Welding Seam Tracker is an important supplementary unit equipped in various kinds of Welding Equipment, including: Welding Column and Boom, H Beam Fabrication Machine, and Pipe Welding Machine, etc.

2) Purpose of Welding Seam Tracker is to trace on actual position of welding torch during welding operation, and controlling on this position accordingly, so as to guarantee on consistent precise and accurate position of welding torch, and hence superior welding quality, in the entire working period of Welding Equipment;

3) Please check attached the 2nd photo on the welding seam tracker equipped in Automatic Column and Boom, and how does it fit into the entire welding operation process, at working site:

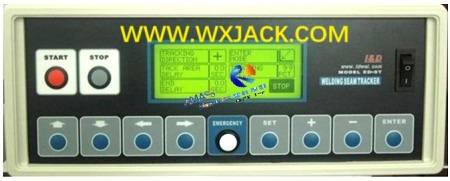

Welding seam tracker unit being equipped in welding machine tool: (Fig.1)

4) Benefit of Welding Seam Tracker being Applied in Cross Slides Column and Boom:

a) Strong Point for Application: The Welding Manipulator with welding seam tracker is the “high tech” product of Welding Equipment: Equipped with this optional welding seam tracing unit, the automatic High Precision welding machinery can fulfil on various welding mode (SAW/ CO2/TIG/MIG) on workpieces in designated accuracy, without human intervention in the welding process;

b) Operator only needs to set process control parameters and validate it at the start up of equipment operation.

2. Technical Brief on LHC High Precision Automatic Welding Column and Boom with Seam Tracker:

1) Purpose of Welding Seam Tracker in Cross Slides Column and Boom:

During the entire welding process, this welding seam tracker traces on actual real time position of welding torch, and manipulates on the position to optimum condition. This is for the target of delivering the best welding quality all the while, in controllable manner;

2) Origin of Welding Seam Tracker: This welding supplementary function mechanism is outsourced component in Welding Equipment, purchased from first class professional supplier in the industry;

3) Constitutes of Welding Seam Tracker: This welding assistant unit consists of sensor, control box and actuator (motorized slider), etc.

4) Working Principle of Welding Seam Tracker in Welding Equipment:

a) Data on welding face variation is collected by sensor which touches workpiece during welding, and calculated by control system;

b) Distance between welding torch and workpiece would be adjusted accordingly when it is necessary by actuator, assuring on the top grade welding quality on fabricated workpiece;

5) Structure and Components of welding seam tracker in the Welding Column and Boom: (Fig.2)

a) This sensor adopts imported components and advanced assembly technology from the Ministry of Aviation and Aerospace, with high quality, long service life;

b) The two dimensional probe sensor: This probe sensor is applicable to overlap welding/ Fillet welding/ Butt welding adopted in Welding Equipment. Different probes, like mushroom type, Y type and roller type etc., are available for different workpieces of Welding Column and Boom;

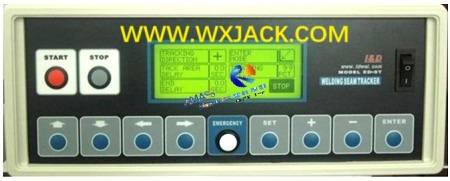

6) Controller of Welding Seam Tracker Applied in Welding Manipulator: (Fig.3)

a) Technical Strong Points: Using the latest CPU as its core part and assembled with anti-jamming control procedure, this controller is highly efficient and reliable. It has user friendly interface, light touching keys with 100k time’s life circle and graphics LCD, all of which make it much easier to operate, set procedure and control, during running of the Welding Manipulator;

b) When being equipped in the LHZ series Cross Slides Column and Boom, this controller is installed at of the front end of horizontal boom:

Controller of welding seam tracker being installed at front end of horizontal boom: (Fig.4)

7) Actuator of Welding Seam Tracker in the Cross Slides Column and Boom: (Fig.5)

a) Brief: This actuator is motorized high precision sliders, with once through shape aluminum cover and reasonable compact structure;

b) Structure: Inside, it uses straight line rail which runs fast and easily. It uses DC low voltage (DC 24V) motor as its drive element, which conforms to European, American and many other countries safety standards;

c) Function: In the process of Welding Column and Boom operation, this actuator serves as executing unit, for adjusting on welding torch position during welding operation;

8) Model Selection on Welding Seam Tracker in the Welding Manipulator:

There are 3 standard models of this welding seam tracing unit to choose from when applied in various kinds of Welding Equipment:

a) ED-ST05 is for MIG/ TIG/ CO2 welding;

b) ED-ST10 is for SAW (Submerged arc welding);

c) ED-ST20 is for Tandem SAW;

For detailed technical parameters of the welding seam tracker, we will provide its manual as part of the technical documents of the LHZ series Precise Automatic Welding Column and Boom.

3. Technical Parameters of LHZ High Precision Automatic Welding Manipulator:

LHZ High Precision Automatic Welding Column and Boom |

Model | LHZ 2×3 | LHZ 3×4 | LHZ 4×4 | LHZ 4×5 | LHZ 5×5 | LHZ 5×6 | LHZ 6×6 | LHZ 7×7 | LHZ 8×8 |

Boom Vertical Valid Stroke (mm) | 2000 | 3000 | 4000 | 4000 | 5000 | 5000 | 6000 | 7000 | 8000 |

Boom Horizontal Valid Stroke (mm) | 3000 | 4000 | 4000 | 5000 | 5000 | 6000 | 6000 | 7000 | 8000 |

Boom Vertical Speed (mm/min.) | 1000 | 1500 |

Boom Horizontal Speed (mm/min.) | 120 ~ 1200/ | 80 ~ 1000 |

Max. Loading at Front End of Boom (kg) | 80 | 80~ 120 | 200 | 500 | 400 |

Welding Seam Tracking Range | 100 ~ 200 mm |

Welding Seam Tracking Speed | 200 ~ 250 mm/min. |

Welding Seam Tracking Precision | ± 0.25 mm |

Welding Seam Tracker Applicable Welding Mode | SAW/ Tandem SAW/ CO2/ TIG/ MIG |

|

|

|

|

|

|

|

|

|

|

|

|

|