Internal baffle, or baffle plate, is the sub-assembly of BOX Beam production, or interim products in the process of BOX Beam produce. The GZ12 BOX Beam Internal Baffle Assembly machine is for making this half-finished product from raw materials of cut plate. It is the first critical step in BOX Beam production.

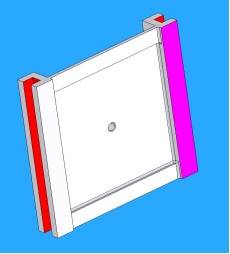

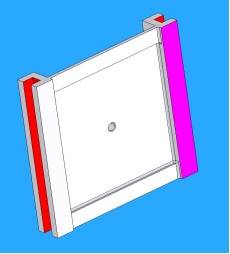

A sketch of internal baffle is as below: (Fig.1)

The baffle plate produced with this BOX Beam Internal Baffle Assembly and Welding machine please see attached picture.

1. Technical Specialty of the BOX Beam Internal Baffle Assembly Machine:

1) This Internal Baffle Assembly machine is specifically designed for assembly and welding of internal baffles of

BOX Beam. In other words, it is a dedicated equipment, not universal machine in the BOX Beam Production Line;

2) There is positioning unit on its work table, which performs assembling job of this Internal Baffle Assembling

machine, and can be moved and adjusted along the work table according to various sizes of workpiece, making

the precise positioning and assembly of internal baffle, and avoiding welding deformation happen;

3) To start the work, first place the raw material of cut plates onto work table of this Internal Baffle Assembling

and Welding machine;

4) After positioning of the cut plates, manually press and secure it tightly. In this equipment, the press and hold

on of workpiece is by means of air cylinder;

5) This is the first step of assembling;

6) The second step of welding of the positioned cut plates into internal baffle is performed following that, in the

manner of manual welding;

7) To adjust position of workpiece, the work table of this Internal Baffle Assembly and Welding machine can be

rotated driven with motor reducer within the range of ±180° in constant speed, leading workpiece revolving

correspondingly, making it at the best position for assembly and welding operation.

2. Technical Parameters of the BOX Beam Internal Baffle Assembly Machine:

Of this BOX Beam Internal Baffle Assembling and Welding machine:

1) Baffle size: 300~1200mm

2) Baffle thickness: ≤80mm

3) Flip motor power: 1.5kW

4) Flip speed: 1.8rpm

5) Work table loading capacity: 1000kg

6) Height of flip-center: 1200mm

7) Flip range of Work table: ±180°

3. Workpiece Specification of the BOX Beam Internal Baffle Assembly Machine:

The baffle plates produced with this BOX Beam Internal Baffle Assembling machine is for making BOX Beam of:

Model | BOX1200 |

BOX Beam Cross Section H×W (mm) | 300×300∽1200×1200 |

BOX Beam Length (mm) | 3000∽12000 |

Max. Work-piece weight | 20 Ton. |