1. The Specialty of Double Table Top Fixture type Welding Positioner:

1) As can be checked from attached photos, the double table top Fixture type Welding Turning Table gets product name from its appearance looking like a set of Welding Fixture;

2) In fact, this Fixture type Weld Positioning Equipment can be viewed a Welding Fixture installed with motor reducer, for realizing its motor drive workpiece revolve, for carrying out welding operation;

3) At some Construction Machinery facilities, such as Cab plant, or Operator Station facilities, such Fixture type Weld Positioner is used for manual welding

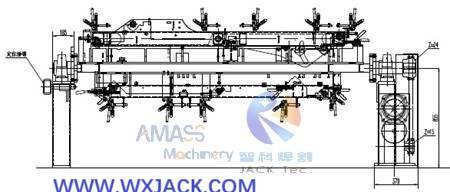

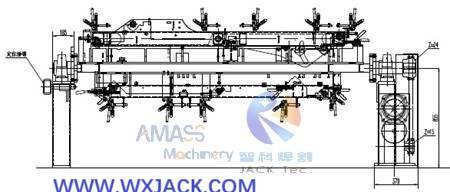

The attached photos were taken at such workshop: (Fig.1)

2. Work Principle of Double Connection Fixture type Welding Turning Table:

In view of operating way, this Fixture type Welding Positioner is similar to the previous product of “Double work table universal applied models”:

1) One Degree of Freedom, that workpiece can revolve on the Welding Fixture, around the shaft joining the two ends;

2) 0°~360° Infinite Revolve of workpiece, in constant or adjustable varying speed of the Welding Turning Table;

3) Driving and idler: One side of the Welding Turning Table (Head stock) is driving type, and the other end (Tail stock) is follower type.

3. Characteristics of Double Table Top Welding Fixture type Welding Positioner:

On the other side, there are many differences with this double work table fixture type equipment:

1) Lessening Down the Original Welding Turning Table:

As can be seen from the attached photos, it weakens design of the two Welding Turning Table at both ends, into more approaching to two connections. This is completely different from conventional Double Table Top Lifting and Rotation Welding Positioner;

Fixture type Welding Turning Table: (Fig.2)

2) Strengthen the Intermediary Bracket into New Welding Turning Table:

a) It enhances design on the connecting bracket joining the two ends of connections, making it a real sense Welding Turning Table;

b) Actually, the most important working section of this Welding Fixture type Weld Positioner is its middle part of the intermediary Welding Turning Table, which is the genuine worktable of the welding equipment, serving as the holding and turning unit of the workpiece;

Fixture type Welding Turning Table at customer workshop: (Fig.3)

c) The specific design on this intermediary welding equipment products varies from case to case, which is similar to sole purpose Welding Fixture;

d) Due to its orientation of horizontal direction, we can call this type of Weld Positioning Equipment as horizontal Fixture structure models.

4. Convenient Fit of Workpiece onto Welding Turning Table into Fixture type Welding Positioner:

1) Three Advantages of Workpiece Fit in Fixture type Welding Positioner:

a) With several pieces of quick pliers deployed on the Welding Turning Table, the workpiece can be positioned into place and secured firmly within seconds. This is one of its advantages of easy fit up in such Weld Positioning Equipment;

Fixture type Welding Turning Table: (Fig.4)

b) Besides, another merit with this kind of horizontal Fixture type equipment is the holding unit can have both sides clamped with workpiece. So, two pieces of workpiece can be welded at the same time;

c) The 3rd strong point is its Welding Turning Table, which is actually work table, has lower level of height than of the Universal Round Table Welding Positioner, which is a good point ergonomics for operator to perform comfortable welding job;

Wuxi JACK Fixture type Welding Turning Table: (Fig.5)

2) Design of Welding Turning Table:

a) The design on location of quick up pliers on the Welding Turning Table, allows for different structures of workpiece can be fixed onto this horizontal Fixture type Weld Positioner;

b) So long as length of the workpiece is less than length of the Welding Turning Table (work table), the workpieces of various length can be welded on this special design welding equipment, without the necessity of adjusting both ends of connections;

c) In real application, the two ends connection of the Welding Turning Table are fixed and are available for modulation.

5. Summary on the Double Table Top Welding Fixture type Welding Positioner:

1) With all the above discussed advantages, these branch of welding positioning equipment have wide application at plants producing Vehicle, Construction Machinery, Engineering machinery, etc. It is a common purpose production machine tool;

2) This sub group of Welding Positioner (Welding Fixture) should be classified as special made. The design on both sides of connections, and the intermediate holding Welding Turning Table, varies on specific customer needs. So, there is no specific technical parameters here.