1. Working of Heavy duty Moving Welding Column and Boom at Customer Site:

1) Working Site: The attached and below small photo gives appearance on how does Wuxi JACK LHZ6050 model Heavy duty Welding Console Manipulator operates at customer workshop: (Fig.1)

Applicable Workpieces: Large diameter tanks were being laid on Welding Rotator in a row. With movement of Moving Welding Console Manipulator along its rails, the tanks can be completed jointed welding external and internal longitudinal and circumferential seams. This is a typical Welding Center being applied in Petrochemical Industry;

2) The column rotation is not frequent under such scenarios. So, its upright column is turned by hand for rotation, thus for reaching different operating zone.

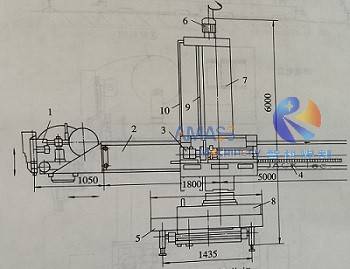

2. Design Sketch of Heavy duty Moving Welding Console Manipulator:

1) The heavy duty Welding Column and Boom of this product section is equipped with moving trolley. Compared with stationary type models, motor drive configuration trolley is more often seen in application of these heavy duty Tank Welding Equipment;

2) Just as reference, below is draft sketch of a set of Wuxi JACK LHT heavy duty Moving Welding Console Manipulator: (Fig.2)

3. Structure and Characteristic of Heavy duty Moving Welding Column and Boom:

A. Mechanical System of Welding Console Manipulator:

1) Mechanical system of LHZ model welding equipment mainly consists of upright column, horizontal boom, cross slides saddle, and moving trolley;

2) Horizontal Boom elevating motor is installed at top of the upright column, which drives boom up and down with the transmission of chain sprocket, to adjust welding position in the Welding Center;

3) Braking type Motor: Horizontal Boom elevating motor installed into Welding Column and Boom is braking type, guaranteeing on accurate and firm stop positioning of the horizontal boom, also avoiding hidden risk of creeping, in the working period;

4) Heavy duty High Precision Cross Roll Bearing: Bottom of upright column is assembled into motor drive moving trolley by way of cross roll bearing (slewing support), driving the horizontal boom rotation in the horizontal plane, realizing fitting and welding on several pieces of workpieces one time, in this set of convenient Welding Column and Boom:

Painted cross roll bearing, horizontal boom, and upright column ready for shipment: (Fig.3)

5) Cross Slides Saddle of Wuxi JACK Heavy duty Welding Console Manipulator: (Fig.4)

a) Horizontal Boom is mounted onto column thru saddle, fulfilling its vertical and horizontal smooth movement. The front head of boom is fit with motor drive cross slides of welding torch, and its end is fit with wire spool, gaining balance of the entire set of Welding Console Manipulator;

b) Welding wire is joint to the welding torch by way of the wire linear on the welding arm. In this way, forming the welding supplementary unit of the Welding Center;

B. Welding System in Welding Console Manipulator and Welding Center:

Taking SAW (Submerged Arc Welding, which accounts for majority use in welding mode of Tank Welding Equipment) as example:

1) SAW Power Source: Optional Brand: Sweden ESAB/ U.S.A. Lincoln/ Chinese HUAYUAN;

2) SAW Welding Wire Feeder: Equipped together with welding power source;

3) SAW Welding Flux Recovery Unit: Chinese LianTong brand;

4) Welding Seam Tracing unit: For acquiring controllable superior welding quality. This is optional, Chinese I&D brand;

5) Video Monitor: When the Welding Column and Boom carry out internal welding inside small diameter cylinder workpiece, which is difficult to get access;

C. Electric System of Heavy duty Moving Welding Console Manipulator:

1) Electric control system of this Welding Center, which combines Welding Console Manipulator and Welding Rotator is integral style, mainly composed of control board, operating panel, remote control pendant, and interface with welding units listed above, as well as with other welding equipment;

2) Brand of the electric control components used in this high quality Welding Center is renowned ones, such as SIEMENS, Schneider, etc.;

3) Control cabinet is dust proof and ventilating, IP40 protection level.

4. Technical Parameters of LHZ Manual Revolve Heavy duty Moving Welding Console Manipulator:

Standard LHZ Column Manual Revolve Traveling Trolley Heavy duty Welding Column and Boom |

Model | LHZ 5×5 | LHZ 5×6 | LHZ 6×6 | LHZ 7×7 | LHZ 8×8 |

Boom Vertical Movement Stroke (mm) | 5000 | 5000 | 6000 | 7000 | 8000 |

Boom Horizontal Moving Stroke (mm) | 5000 | 6000 | 6000 | 7000 | 8000 |

Boom Vertical Moving Speed (mm/min.) | 1000/ 1500(for 7×7 and above) |

Boom Horizontal Moving Speed (mm/min.) | 120 ~ 1200/ 80 ~ 1000 (for 7×7 and above) |

Min. Distance between Boom Bottom and Rail Surface (mm) | 740 ~ 1180/1300 (for 5×6 and above) |

Max. Loading at Front End of Boom (kg) | 200 | 500 | 400 |

Column Revolve Way | Manual, and locked with lever or air cylinder |

Trolley Travel Speed (mm/min.) | 2000 |

Inner Span of Trolley Rail (mm) | 1730 | 2000 | 2500 |