1. Outline on Working Features of Light duty Manual Revolve Traveling Welding Manipulator:

1) Additional Functions: The Light duty Welding Manipulator of this product section, compared with the earlier introduced 2 types of fixed base: Stationary Manual Revolve models, and Stationary Electric Motor Revolve models, has added ability of moving along rails driven under motor;

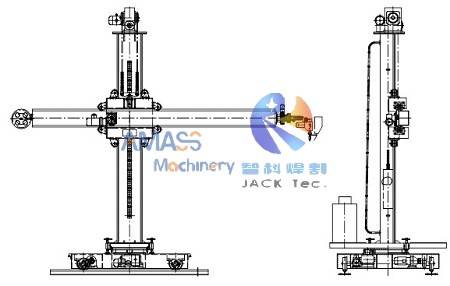

2) With this additional degree of freedom, such Welding Equipment is a kind of moving capability welding machinery of cross structure. As can be seen from attached master photo and below, the machine has a trolley base moving on parallel rails:

Motorized trolley of Wuxi JACK moving Welding Column and Boom: (Fig.1)

2. Structure and Composition of Light duty Manual Turning Moving Welding Column and Boom:

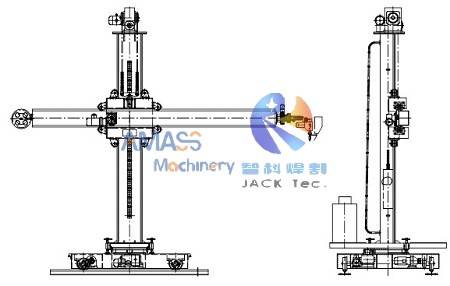

1) Typical structure of a set of traveling style Cross Slide welding equipment can be seen from below sketch:

Design sketch of Wuxi JACK motor drive moving Welding Column and Boom: (Fig.2)

2) Checking from the above sketch and attached photos, a set of classical automatic moving Welding Manipulator is assembled into being in the form of modular assembly;

3) Working parts of any set of the welding machinery can be divided into 2 groups of standard and optional. Of which, the standard elementary units are indispensable for a set of the cross slide welding machine tool, which builds up skeleton of this Welding Equipment;

4) Optional Functions: Meanwhile, optional function units make this Welding Equipment into a more powerful, versatile and special purpose product. For example, with Strip Cladding.

3. Basic Standard Components in Welding Column and Boom:

1) Mechanical Base Bed:

It is foundation for this type of Welding Equipment, including stationary base bed for Fixed Base models, and movable trolley for motor drive models;

2) Upright Column:

This unit is of fixed manner in terms of elevation and horizontal movement, and of revolving manner in manual and or motor drive mode;

3) Horizontal Boom:

This is working hand in any set of Welding Manipulator, with capabilities of both X axis movement, and Y axis up and down;

4) Cross Slide:

The other name of cross slides is saddle. In operation of Welding Column and Boom, it plays role of hinge and pivot for position change of welding torch;

5) Slewing Support for Column Revolve:

This is outsourced part in Welding Column and Boom, making sure accurate, stable, and smooth rotating positioning of column, during working period;

6) Welding Unit:

This is indispensable working cell in any kind of Welding Equipment, including welding torch and welding power source;

7) SAW Welding Flux Recovery Unit:

This is unique configuration in SAW Welding Column and Boom, including flux hopper, flux recycling machine, flux sending tube, etc.

4. Welding Supplementary Unit in Welding Manipulator:

Significance: This group guarantees on smooth and satisfactory welding operation. It belongs to optional units, but are selected by customers in majority conditions, including:

1) Welding Seam Tracing Unit:

There is a laser generator equipped on the welding torch of the Welding Manipulator, which indicates on actual position of welding torch during welding: Whether the position is correct, or offset;

2) Video Monitor:

a) Function: This is especially useful, when the welding equipment performs internal circumferential seam welding inside tube: The horizontal Boom extends into the pipe, the video monitor can give real time information on what is happening inside the workpiece tube:

Video camera being applied in Wuxi JACK Welding Column and Boom: (Fig.3)

b) The other Welding Equipment utilizing this unit is Large Pipe Internal Welding Machine;

3) Strip Surfacing Unit with Strip Cladding:

This is unique configuration in built up welding mode.

5. Drive and Transmission in Welding Column and Boom:

1) The Horizontal Boom Horizonal Movement:

This direction involves welding process. It is driven with motor reducer, and transmitted with gear and rack, making the equipment a high precision Welding Column and Boom;

2) The Horizontal Boom Elevation Movement:

Driven with motor reducer. As to transmission, for light duty models Welding Manipulator, as introduced in the previous product, it is by means of leadscrew; For medium duty and heavy duty models, it is by means of chain sprocket;

3) Motor Drive Trolley of Moving type Welding Manipulator:

Driven and transmitted with motor reducer, in the speed of constant 1700 mm/min. for light duty models equipment, and 2000mm/min. for medium duty and heavy duty Welding Column and Boom.

6. Technical Parameters of Light duty Manual Revolve Traveling Welding Manipulator:

Standard LHZ Light duty Column Manual Revolve Traveling Welding Column and Boom |

Model | LHZ 2×2 | LHZ 2.5×2.5 | LHZ 2.5×3 |

Boom Vertical Up and Down Stroke (mm) | 2000 | 2500 | 2500 |

Boom Horizontal Extending Stroke (mm) | 2000 | 2500 | 3000 |

Boom Vertical Up and Down Speed (mm/min.) | 1000 |

Boom Horizontal Extending Speed (mm/min.) | 120 ~ 1200 |

Min. Distance between Boom Bottom and Rail Top Surface (mm) | 740 |

Max. Loading at Front End of Boom (kg) | 80 |

Column Revolve Manner | Manual, and locked with lever or air cylinder |

Trolley Travel Speed(mm/min.) | 1700, Fixed |

Inner Span of Trolley Rail (mm) | 1000 |