A. The Formation and Target Market for 7 Axis 3000/6 Large Size Flame Plasma CNC Pipe Intersection Cutting Machine:

1. Formation of the 7 Axis 3000/6 Large Size CNC Pipe Cutting Machine:

1) Same as 7 Axis 3000/9, the model of 7 Axis 3000/6 is also derivative product of 7 Axis 3000/12 Large Size CNC Pipe Cutting Machine: It has half of cutting torch traveling stroke, along pipe lengthways direction (X axis), as that of the 3000/12 specification Large Size CNC Pipe Intersection Cut Equipment;

2) Other specifications and parameters of the 2 models are similar;

2. Target Market of 7 Axis 3000/6 Flame Plasma CNC Pipe Intersection Cut Equipment:

1) Some of customers produce large diameter tanks with relatively short length. By this time, this 7 Axis 3000/6 Large Size CNC Pipe Cutting Machine is perfect choice: It meet the requirement on large size pipe cutting and beveling, with obvious lower machine quotation;

2) Anyway, in manufacturing cost of CP series Flame Plasma CNC Pipe Intersection Cutting Machine, 50% less pipe length and hence machine length means at least 20% ~30% reduction of machine total price. Because components and assemblies of mechanical system take fairly percentage, in total cost of the CNC Pipe Cutting Machine;

3) So, let us have a brief review on mechanical system of the Large Size CNC Pipe Intersection Cutting Machine as below.

B. Mechanical System of 7 Axis 3000/6 Large Size Flame Plasma CNC Pipe Cutting Machine:

1. Below is mechanical frame of a set of 3000/6 Large Size CNC Pipe Cutting Machine in production at Wuxi JACK facility: (Fig.1)

2. From the above photo we can see that, mechanical body of Large Size CNC Pipe Cutting Machine has 2 main units of:

1) The lengthwise mechanical frame, installed with pipe length direction precise linear guiderail for guiding movement of cutting torch, together with transmission purpose gear and rack;

2) Workpiece pipe supporting and revolving friction rollers set;

3. From above we can find that, manufacturing cost of both the above units are in direct proportional with pipe length, and hence model of the Flame Plasma CNC Pipe Intersection Cut Equipment: /12/9/6...

4. This is the reason why we have sub-division on models of CP series Flame Plasma CNC Pipe Cutting Machine in pipe length grades.

C. Precise Beveling Unit in Flame Plasma CNC Pipe Intersection Cutting Machine:

1. Advanced software is not the only technical know-how on guaranteeing successful running of Wuxi JACK CNC Pipe Cutting Machine;

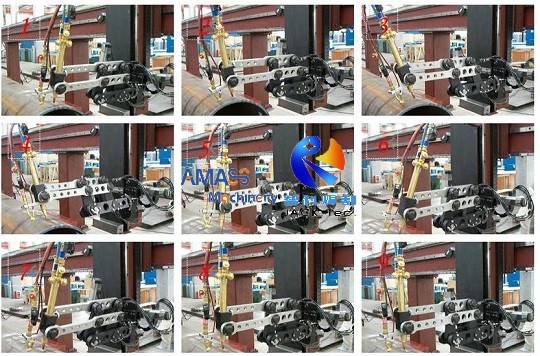

2. The hardware manipulators are also key working parts, on making sure delivery of high standard beveling effect from the CNC Pipe Cutting Machine: (Fig.2)

1) As can be observed from the above photo, all the grooving units in CNC Pipe Intersection Cutting Machine are connected together by means of rolling bearings, which has small clearance and high precision;

2) Besides, the axial fixation of these rolling bearing is realized with a group of small size round nuts, avoiding potential risk of precision deterioration, which may be caused from clearance after long term running of the flame plasma CNC Pipe Cutting Machine;

3) Also, the 2 sets of servo driving system of grooving unit, which are enforcement unit of A axis and B Axis, are assembled with precise gear couple and close fitting bush. So, there is no clearance affecting precision of finished grooving, from the CNC Pipe Intersection Cutting Machine;

4) The final assembly of complete set of CNC Pipe Intersection Cut Equipment makes sure that, the clearance of gear engaging is adjustable;

3. All of these optimization measures taken, during design and manufacture of the CNC Pipe Cutting Machine, fully guarantee its cutting precision generated: Even after long time use of the CNC Pipe Intersection Cut Equipment, there is no defect happened such as shivering, which may affect cutting kerf smoothness and accuracy.

D. Operation View on 7 Axis 3000/6 Large Size Flame Plasma CNC Pipe Cutting Machine:

1. Summing up, this 7 Axis Large Size CNC Pipe Cutting Machine can fulfil pipe cutting and beveling jobs in the highest degree of complex and precision;

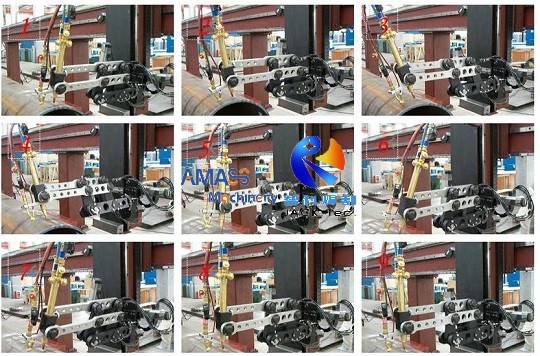

2. As an example, below is snapshot of 9 frames recording on a typical hole cutting and beveling process, in 7 Axis and 5 Axis CNC Pipe Intersection Cutting Machine: (Fig.3)

E. Technical Parameters of 7 Axis 3000/6 Flame Plasma Large Size CNC Pipe Cutting Machine:

Below is specification of 7 Axis 3000/6 Flame and Plasma Large Size CNC Pipe Intersection Cut Equipment:

Model Technical Parameter | 7 Axis CNC-CP 3000/6 Large Size Flame Plasma CNC Pipe Intersection Cutting Machine |

Applicative Pipe Diameter Range | 600 ~ 3000 (mm) |

Applicative Max. Pipe Length | 6000 (mm) |

Applicative Pipe Thickness Range | 6~100 mm for flame cutting 3 ~ 25mm for plasma cutting |

Applicative Flame and Plasma Cutting Speed | 200∼800mm/min. for flame cutting Around 200~ 2000mm/min. for plasma cutting (Based on thickness of Pipe and Plasma Power) |

Effective CNC Control Axis | 7 Axis of X/Y/Z/A/B/V/W X Axis: For cutting along pipe length direction; Y Axis: For managing pipe rotation; Z Axis: For accommodating pipe diameter change; A Axis: For controlling cutting torch tilt along pipe radius; B Axis: For controlling cutting torch tilt along pipe length; V Axis: For changing cutting torch position along pipe radius; W Axis: For changing pipe holding turning rollers position |