1. Working Environment of 3 in 1 H Beam Welding Machine:

1) As shown in the 1st photo, this is a typical working scenario for H Beam Fabrication Machine: In an overseas steel structure workshop, at the back side (Material incoming side) of the PHJ models machine, there is a set of CNC Strip Plate Cutting Machine, which is the upstream station for the PHJ Vertical H Beam Welder, providing its raw materials flange and web;

2) In this product section we will focus on design aspect of Wuxi JACK PHJ series machine.

2. Design Starting Point of PHJ Series I Beam Assembly Weld Straighten Integral Machine:

1) Every people who is familiar with steel structure equipment, when first take a look on the PHJ series 3 in 1 H Beam Welding Machine, will associate it with H Beam Assembly and Tack Welding Machine:

Wuxi JACK Z15 H Beam Assembly and Tack Welding Machine: (Fig.1)

2) Yes, this is the design starting point and inspiration on PHJ series Integral Function Vertical H Beam Welder, that it is used as reference on structure and assembling principle from the H Beam Assembly Machine;

3) So, what is the reason behind that? --- Because in the three steps of welded H Beam production, H Beam assembly is the most complicated one with strict demand on accuracy, which determines correctness of workpiece to be delivered. In traditional H Beam Assembly Machine, first flange and web are fitted up, then tack welded to strengthen its shape, and following that sent to H Beam Submerged Arc Welding Machine;

4) Update on Mechanical Structure of PHJ Series 3 in 1 H Beam Welding Machine:

Correspondingly, in the PHJ series machine, the general structure and working unit of the H Beam Assembly Machine is adjusted as follow:

a) Introduce submerged arc welding cell directly, and remove the original CO2 tack welding;

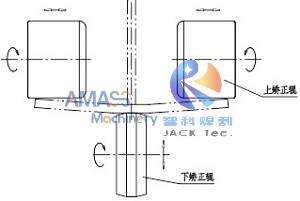

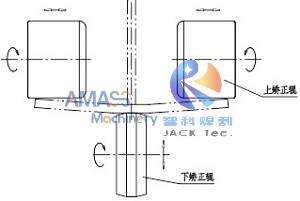

b) Following welding cell, add on the straightening cell at outlet of the Vertical H Beam Welder mechanical main frame. The straightening principle is same as that of the HYJ and YTJ series H Beam Straightening Machine:

Straightening principle indication on 3 in 1 H Beam Assembly Weld Straighten Integral Machine: (Fig.2)

c) In this way, the general picture on central working zone of a set of PHJ series Integral Function H Beam Welding Machine come into being:

Central function zone: Assembly, welding and straightening units in Wuxi JACK 3 in 1 H Beam Welding Machine: (Fig.3)

d) This is the reason that, although taking the same duty of SAW in making H Beam, PHJ series Vertical H Beam Welder has completely different structure/ appearance/ working principle with LHA /LHT / LHC models H Beam Submerged Machine;

5) Welding Position in PHJ Series Vertical H Beam Welder:

a) This also explains that, why for the LHA/ LHT/ LHC models H Beam Submerged Arc Welding Machine, it can perform SAW on workpiece in 45° of more than one time, which is applicable for making heavy weight workpiece of large welding size. See below:

45° fillet SAW ( Submerged arc welding) in SAW H Beam Welding Machine: (Fig.4)

b) While for PHJ and ZHJ series machine, it performs single pass welding along workpiece, which is applicable for making light and medium weight workpiece of middle welding seam:

0° fillet Welding operation in 3 in 1 H Beam Welding Machine: (Fig.5)

3. Design Principles of PHJ Series Integral Function H Beam Fabrication Machine:

PHJ and ZHJ machine is a sophisticated equipment, which is not designed in the simple way of “Copy and Paste”. A series of rules are abided by throughout its entire design stage. Which, here we just list the several prominent ones:

1) Simplicity and Compactness of Integral Function H Beam Welding Machine:

a) The original intention on developing the machine is to simplify manufacturing process on light and medium size H Beam /T Beam, raising value added time and decreasing non-value added time;

b) Just like organs in human being, every sub-assembly/ unit in the machine has its usage in perfect size, no any redundant and or over sized ones;

2) Safety and User Friendliness of 3 in 1 I H Beam Assembly Weld Straighten Integral Machine:

a) People always rank first in manufacturing industry;

b) The design of PHJ and ZHJ series machine take every detail into consideration on this aspect. For detail, please check the product page of H Beam Fabrication Machine;

3) Overall and Delicacy of H Beam Fabrication Machine:

a) Please check the 2nd and 3rd photos. Design of the PHJ and ZHJ series machine not only consider overall compatibility, but also delicacy in detail. In the attached 2nd photo, which was taken at assembling area of the machine, the earthing pole/ photoelectric limit switch/ mini-uplift gadget are reasonable arranged, guaranteeing security/ accuracy of assembling process;

b) As shown in the attached 3rd photo, the design on pulling rod box of the H Beam Fabrication Machine draw reference from bionics, that it works like “claw” to grip the raw material during its feed-in of the machine;

4) Symmetry and Aesthetics of Wuxi JACK 3 in 1 H Beam Welding Machine:

The attached 4th/5th /6th photos fully demonstrate that, in the design of Wuxi JACK PHJ and ZHJ Vertical H Beam Welder, besides its practicability, the symmetry and aesthetics are also never missed, on both structure and color matching of the machine.

4. Technical Parameters of PHJ Model H Beam Fabrication Machine:

Technical Parameter | PHJ 3 in 1 H Beam Welding Machine |

H Beam Web Size | Height: 200 ∼ 1500/ 1800/ 2000 mm; Thickness: 5 ∼ 30 mm |

H Beam Flange Size | Width: 200 ∼ 800 mm; Thickness: 6 ∼ 40 mm |

Workpiece (Welding H Beam) Length | 3000 ∼ 15000 mm (At customer demand) |

Working Speed of Assembly/ Welding Straightening | 200∼1200 mm/min.; Working speed 500~700mm/min. for 10~12mm thickness workpiece(Stepless, inverter control, VFD) |

Welding Seam | One Pass of max. size 8~12 mm |

Workpiece | Symmetric and Asymmetric Section Shape Welding H Beam/ I Beam/ T Beam |

Machine Overall Dimension(L×W×H) | 28m × 4m × 4.8m |

Input and Output Conveyor | 10~11m length in 3 segments each; One with motor, two followers; Input conveyor with 2 sets of hydraulic manipulators |

Driving Mode | Flange and Web Alignment Rollers/ Straightening/ Output conveyor elevation: Hydraulic cylinder |

Welding Mode | Single Arc or Twin Arc SAW at fillet flat position |

Hydraulic System Specification | Working Pressure: 6~ 8 MPa; Driving Power: 4.4kW |

Main Driving Motor | 5.5kW |

Flange and web Assembling | One side hydraulic cylinder, the other side manual leadscrew |