A. Usage and Application of HR800 High Speed H Beam Flange Edge Deburring and Rounding Machine:

1. Function: HR series H Beam Flange Edge Rounding Machine is a kind of small minority product, for completing polishing/ deburring/ rounding on both sides flange edges of steel structure H Beam;

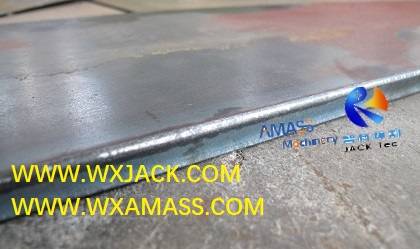

2. Photo View: Local amplification on workpiece H Beam, being trimmed in working zone of Wuxi JACK High Speed H Beam Flange Edge Rounding Machine: (Fig.1)

3. Applicating Field of HR series Edge Trimming and Rounding Machine:

1) In practical application, HR models Edge Rounding Machine can not only be applied for edge trimming on H Beam flanges,

2) But also on carbon steel plates/ other non-ferrous metal sheet metal/ T Beam/ Any other right angle steel structure workpieces;

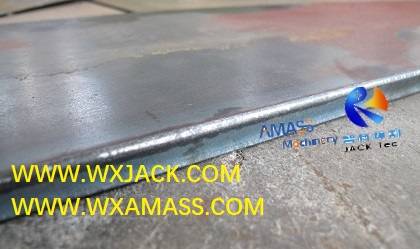

3) The rounded steel plate delivered from Wuxi JACK HR800 Edge Deburring and Rounding Machine: (Fig.2)

4) For this reason, HR800 H Beam Flange Edge Rounding Machine has overlapping function as RH series Sheet Metal Plate Edge Deburring and Rounding Machine;

4. Suitable Specifications of Working Parts in HR800 H Beam Flange Edge Deburring and Rounding Machine:

The H Beam to be processed in this Edge Rounding Machine sees more light and medium duty ones:

1) Thickness of H Beam flange or metal plate ranges from 12mm to 40mm;

2) Width of H Beam flange or metal plate is in the scope of 100mm to 800mm;

3) Length of workpiece can be denoted by customers. Default setting in this Edge Trimming and Rounding Machine is from 1m to 12m;

4) Finished rounded fillet has radius of Diameter 2.5mm: R2.5mm;

5. Industries and Plants Sees Installation of HR Series H Beam Flange Edge Rounding Machine:

1) The typical industry witnesses adoption of H Beam Flange Edge Deburring and Rounding Machine is of course Steel Structure construction sites, where deburred and edge rounded H Beam can get optimum level of painting effect, benefitting from it;

2) Under such condition, the HR model H Beam Flange Edge Rounding Machine is installed at end of line working station, of H Beam Production Line, or following PHJ and ZHJ series H Beam Assembly Welding Straightening Integral Machine.

B. Strong Points and Minimum Workpiece Size of Wuxi JACK RH800 High Speed H Beam Flange Edge Rounding Machine:

1. Positive Features of the RH800 H Beam Flange Edge Trimming and Rounding Machine:

1) High Speed: The edge rounding working velocity can be 7200 mm/min., fairly high efficiency;

2) Reliable Rounding: The positioning of rounding rollers/ sending forward of workpiece/ edge rounding operation are driven with hydraulic oil cylinders, boosting heavy force and dependable running;

3) Easy Operation: The adjustment and managing during working period of H Beam Flange Edge Rounding Machine are fulfilled by means of operating panel/ operating pendant and indicating rulers, intuitive and convenient;

Operating pendant of Wuxi JACK HR models H Beam Flange Edge Deburring and Rounding Machine: (Fig.3)

2. Minimum Workpiece Size in HR800 High Speed Edge Rounding Machine:

Requirement on Small Size H Beam practical for the Edge Trimming and Rounding Machine:

1) To fully guaranteeing edge rounding effect, there is a relationship between small size H Beam flange width and web height, there is precondition on this aspect:

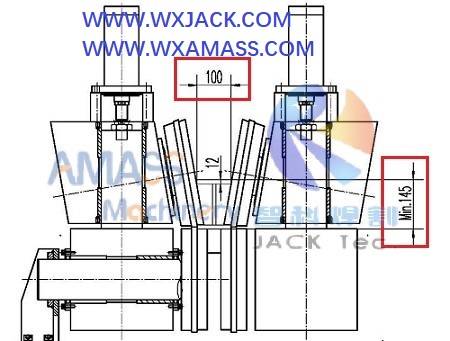

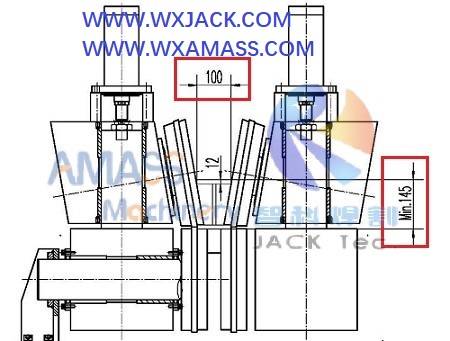

2) When H Beam flange width is kept at the minimum level of 100mm, the corresponding web height should be at least 150mm, shown in below design sketch:

3) Mechanical Structure and Workpiece Held in Wuxi JACK HR800 H Beam Flange Edge Deburring and Rounding Machine: (Fig.4)

C. Technical Features of HR800 High Speed H Beam Flange Edge Trimming and Rounding Machine:

1. Structure and Main Units in the H Beam Flange Edge Deburring and Rounding Machine:

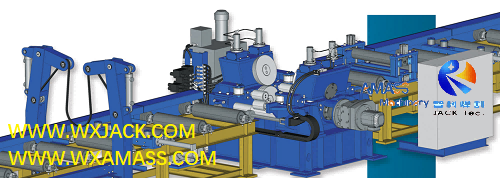

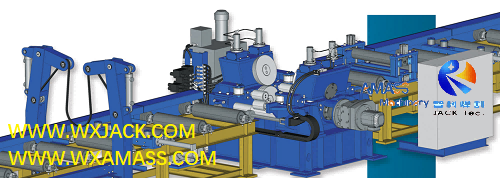

1) Deployment of Wuxi JACK H Beam Flange Edge Trimming and Rounding Machine inside Steel Structure production line: (Fig.5)

2) Workpiece Overturning: As indicated in the above sketch, ahead of this H Beam Flange Edge Rounding Machine, there is a group of 360° Steel Structure Chain Manipulator, for the purpose of flipping the H Beam 180°, to make the H Beam upside down, so as to performing edge rounding on all the 4 corners of H Beam;

3) Manipulating working part H Beam ahead of the H Beam Flange Edge Rounding Machine: (Fig.6)

4) General Layout: One set of the H Beam Flange Edge Deburring and Rounding Machine, includes one group of mechanical main structure, input and output conveyor, hydraulic station, electrical system and control box;

5) Mechanical Main Body of HR800 H Beam Flange Edge Rounding Machine:

a) The machine body of the Edge Rounding Machine composes of fixed base bed/ Stationary edge rounding unit/ movable edge rounding unit/ horizontal guiding unit/ downward pressing unit/ lateral movement roller unit/ horizontal supporting roller;

b) The base bed is welded into solid structure, of which its rigidity and strength has been calculated by Wuxi JACK engineering team before design;

2. Rounding Rollers in the High Speed Edge Rounding Machine:

1) There are 4 pieces of solid and high strength rounding rollers in one set of the Edge Rounding Machine, which are core working element of the equipment;

2) There is strict demand on precision and hardness of these rounding rollers, which in turned is acquired from strict selection on raw material and process technology route of these rounding rollers;

3) Close view on rounding rollers in Wuxi JACK Edge Deburring and Rounding Machine: (Fig.7)

3. Guiding Rollers in the HR800 High Speed H Beam Flange Edge Rounding Machine:

1) To accommodating different width of workpiece, one side of edge rounding unit is fixed, and the opposing side edge rounding unit can be moved in horizontal direction;

2) The movement of movable edge rounding unit is along smooth guiding rod, driven and transmitted with gloss surface guiding rollers and bearing;

3) The lateral movement guiding unit in Wuxi JACK Edge Trimming and Rounding Machine: (Fig.8)

D. Technical Parameters of Wuxi JACK HR800 High Speed H Beam Flange Edge Deburring and Rounding Machine:

Below are primary specifications of this light to medium duty H Beam Flange Edge Trimming and Rounding Machine:

No. | Item | Parameter |

1 | Workpiece Width for Edge Rounding | 100-800 mm |

2 | Workpiece Thickness | 12-40mm (R2.5) |

3 | Work piece Length: | 1000-12000mm |

4 | Suit H Beam Web Height | Please check the fig. 1 |

5 | Edge Rounding Speed | 7200 mm/min |

6 | Gas Pressure | 0.4-0.6 MPa |

7 | Rounding Radius | R2.5mm (Sheet thickness 12-40mm) |

8 | Main Edge Rounding Rollers Diameter | φ300mm |

9 | Suit H Beam Height when Flange is 100mm | 150mm (Please see fig. 1) |

10 | Hydraulic Station | 4 kW |

11 | Max. Pressure in Hydraulic System | 12 MPa |

12 | Input Conveyor Length | 10 m |

13 | Output Conveyor Length | 10 m |

14 | Roller Working Life | 50,000m (according the material) |

15 | The Drive Roller Motor Power | 2.2kW * 2 |

16 | The Roller Table Motor Power | 1.5kW * 2 |

17 | Total Power of the Edge Rounding Machine | 11.4 kW |

18 | Electricity Power | 380V/ 50Hz/ 3P |