A. The Difference and Advantages of SXBJ-3 Function Upgraded CNC Control Sheet Metal Plate Edge Milling Machine:

1. Label: The SXBJ-3 model Plate End Milling Machine introduced in this product section is new generation product, with several state-of-art function cells equipped, on the basis of “Ordinary” configured machine of plate beveling;

2. Benefits for Customers: By means of series of the latest developed function elements to be equipped onto the equipment, this Plate Welding Supporting Equipment can deliver edge milling work on workpieces with the best quality, higher efficiency, and more user friendly operation;

3. What does it Looks Like: The attached 6 pictures show a set of Wuxi JACK SXBJ-3 model Edge Milling Machine with “High End Configuration”, which was exported to Russia in Sep.2021. Check below photo also:

4. The front view on Wuxi JACK SXBJ-3 model machine for edge milling: (Fig.1)

B. Advanced Configurations of Function Upgraded SXBJ-3 CNC Control Sheet Metal Plate End Milling Machine:

This “High End” machine of plate edge beveling has below upgraded function units, making this Plate Welding Supporting Equipment into a genuine sense of Advanced Configuration Steel Plate Edge Milling Machine:

1. HMI Equipped into the Sheet Metal Plate Edge Milling Machine:

1) Usage: In this high end equipment for sheet metal edge milling, HMI (Human machine interface) and touch screen are adopted in its electric control system, for setting up tilting angle of milling head, so as to conveniently and precisely controlling finished angle of welding groove, produced on edges of workpiece steel plate held in the machine worktable;

2) Please check the attached 2nd photo, and below small one:

3) Setting up and displaying edge milling angle with HMI touch screen, of Wuxi JACK SXBJ-3 model high end configuration machine for metal plate edge milling: (Fig.2)

4) As can be observed from the above photo, the digital display in HMI touch screen has strong points of the best degree of accuracy and precise tolerance, during running of the Plate Beveling Machine;

2. Multiway of Milling Angle Display Simultaneously in Welding Supporting Equipment:

1) During period of edge milling work in the machine, besides digital display in touch screen of HMI, the actual tilting angle of milling head is also indicated in precise stainless steel angular ruler in real time manner;

2) The stainless steel angular dial ruler is standard configuration in Wuxi JACK XBJ and SXBJ series Plate Edge Milling Machine;

3) In this way, the multiple styles of milling angle indication is available in the sophisticated SXBJ-3 model CNC control Edge Milling Equipment, offering more choices for operator of the machine. Please check photo below:

4) The stainless angular dial ruler equipped in Wuxi JACK equipment for edge milling on sheet metal plate: (Fig.3)

3. Motor drive and Encoder Command Tilting of Milling Head in Advanced Configured Plate Beveling Machine:

1) Instead of manual manipulating swing of milling head in conventional general purpose machine, here in this advanced function model equipment, the rotating of milling head is driven with A.C. motor and detected by means of proximity switch;

2) The strong points of such arrangement are: It saves labor intensity of machine operator, and manages milling head swinging process of milling head in safe and precise manner. Please check below photo:

3) The motorized and proximity switch detecting milling head revolving mechanism, equipped in Wuxi JACK advanced function Plate Welding Supporting Equipment Edge Milling Machine: (Fig.4)

4. Broader Range of Milling Head Tilting in High End SXBJ-3 Plate Beveling Machine:

1) The default setting on milling head tilting angle range in conventional sheet metal Plate Edge Milling Machine is 0° to 45°. Please see below photo:

2) The standard 0° to 45° swing specification milling head adopted in Wuxi JACK machine for plate end milling: (Fig.5)

3) Special Need: Although the angle range of 0° to 45° can meet majority of customer demand, these do exist certain applicating scenarios, that broader range of milling angle is necessary. Such as 60°, to be available in the Plate Welding Supporting Equipment;

4) Solution: For this reason, Wuxi JACK also has series of special made milling heads, to meet the demand customer requirement on this aspect. The max. tilting angle can be 80° to even 90°. Which means, 0°~ 80° in this quasi CNC control plate Edge Milling Machine, compared with 0°~45° conventional setting. Please see below photo:

5) The special made 0° to 80° milling head adopted in Wuxi JACK machine of plate edge milling : (Fig.6)

5. Hydraulic Drive Auxiliary Loading Mechanisms in High End SXBJ-3 Sheet Metal Plate Edge Milling Machine:

1) This advanced function Plate Welding Supporting Equipment is equipped with hydraulic oil cylinders drive supplementary system;

2) This system is composed of several pieces of oil cylinders drive loading and unloading unit. The quantity of the unit depends on valid max. edge milling stroke of the corresponding models of the machine;

3) This auxiliary unit is for implementing on automatic handling of workpieces steel plate, into and out of the machine worktable for carrying on edge milling on plate. Please check below photo:

4) The rolling roller racks of hydraulic drive supporting material handling system, equipped in Wuxi JACK SXBJ-3 CNC control Plate Edge Milling Machine: (Fig.7)

5) This auxiliary workpiece handling system is very useful for double heads long stroke Plate Edge Milling Machine, especially those models from SXBJ-12 to SXBJ-18;

6. Summing Up on Leading Edge Function Cells adopted in Function Upgraded Grooving SXBJ-3 Welding Supporting Equipment:

1) With the above listed advanced “sharp tools” function units, this SXBJ-3 model double heads CNC Edge Milling Machine can deliver more sophisticated and custom made bevels and chamfers, with the best quality, higher productivity and easy operation:

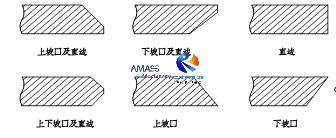

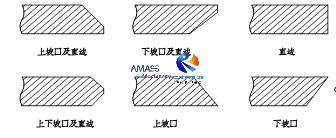

2) The welding grooves that are available to be produced from the machines for acquiring plate edge milling: (Fig.8)

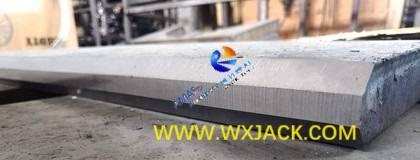

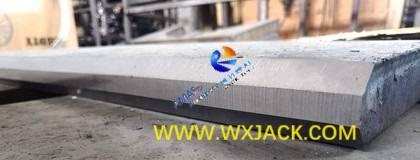

3) The superior quality finished welding groove, fulfilled on edge of workpiece steel plate, produced from Wuxi JACK SXBJ-3 plate End Milling Machine: (Fig.9)

C. Technical Parameters of Plate Welding Supporting Equipment SXBJ-3 Model:

Model Technical Parameter | SXBJ-3 Double Heads CNC Control Sheet Metal Plate End Milling Machine |

Sheet Metal Plate Max. Stroke on Edge Milling | 3000 mm |

Sheet Metal Plate Width Range | 600mm ~ 3000 mm |

Sheet Metal Plate Thickness Range | 6∼40 mm (Based on customer demand) |

Quantity of Hydraulic Drive Clamping Jacks | 7 Pieces |

Milling Head and Moving Carriage Quantity | 2 Sets |

Tilting Angle Range of Top Edge Milling Unit | 0° to +80° |

Tilting Angle Range of Bottom Edge Milling Unit | -45° to 0° |

Milling Head Tilting Angle Management Style | By HMI touch screen and Motor Encoder |

Milling Head Tilting | Driven with A.C. motor |

Workpiece Steel Plate Handling | By hydraulic drive Pushing and Pulling brackets |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm (Higher Power available) |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Milling Unit Traveling Motor Power | 2.2 kW |

Milling Unit Lifting Motor Power | 0.75 kW |

Taper Hole of Milling Spindle End | ISO 50 (7:24) |

Spindle Stroke | 100 mm |

Edge Milling Moving Speed | 150 ∼1000 mm/min. VFD with inverter |

Idle High Moving Speed of Milling Carriage | Fixed 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320 mm (Ø200 mm For delivery) |

Quantity of Hydraulic Jack Screw | 2 sets, intermittently installed |

Worktable Length | 10 m |

Worktable Width | 450 mm |

Worktable Height | 1050 mm |