Judging from its name, we can get the hint that the most conspicuous trait of this product section SXBJ-18 Edge Milling Machine lies in its workpiece clamping unit of jacks.

1. Metal Plate Clamps Jacks of SXBJ-18 Edge Milling Machine:

1) With so many models and designs of Edge Milling Machine introduced up to now, we grow familiar with its working holding unit, which is a line of hydraulic jacks just above worktable;

2) Instead, for the double heads Edge Milling Machine of this product section, the design of its jacks in the attached pictures is the arrangement of hydraulic drive and mechanical manual jacks fitted in turn;

3) The reason on such design on Edge Milling Machine is:

a) The interval between any two immediate adjacent hydraulic jack is 1000 mm, which is not sufficiently to hold the workpiece (steel plate) flatly and tightly during cutting on welding groove on edges of sheet metal;

b) For this reason, a manual turning mechanical jack is fit into the space between any of the two pieces of adjacent hydraulic drive jacks, guaranteeing on sufficient density of workpiece clamping;

4) The advantage of such design in the End Beveling Machine is it is cost reduction compared with all hydraulic drive jacks;

5) The disadvantage of such hybrid design is laborious and time consuming for securing on the workpiece, that each of the mechanical jack need to be turned with hand… Especially for the large stroke Sheet Metal End Beveling equipment, such as this SXBJ-18 model. It will make the total cycle time of edge milling operation in welding groove cutting is obviously longer. For these reasons, which way to choose, the mechanical and hydraulic hybrid or pure hydraulic jacks, is a compromise to be made by customers;

5) As a plain comparison, we attach pictures of both kinds in this product section of Edge Milling Machine, please check.

2. Usage and Traits of the SXBJ-18 Edge Milling Machine:

Now, let’s take a look on the machine as a whole:

1) Edge Milling Machine is put into market as a substitution on Planer Machine in plate edge beveling before welding. Compared with Planer Machine, this machine for edge milling has good points of high productivity, high precision and energy saving. So, it sees more and more application of the Edge Milling Machine over the past decades;

2) This machine can be used for sheet metal edge chamfering on various materials of metal plate, including carbon steel (the widest chose), stainless steel, Al. etc.;

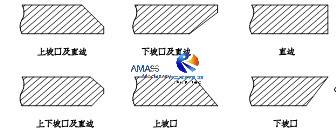

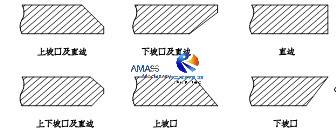

3) The Edge Milling Machine is applicable for implementing on plate end beveling of different kinds (Common seen as below) for the thickness range of 6 ~ 80 mm. Angle of the milling cutter can be adjusted within the scope of 0° ~ 80° at will.

3. Technical Parameters of SXBJ-18 Double Head Edge Milling Machine:

Model Technical Parameter | Hydraulic and Mechanical Hybrid Jacks SXBJ-18 Double Heads Steel Plate Edge Milling Machine |

Max. Plate Edge Milling Length | 18,000 mm |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm (Higher Power available) |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Taper Hole of Milling Spindle End | ISO 50(7:24) |

Spindle Stroke | 100 mm |

Milling Head Quantity | 2 sets |

Plate thickness for Sheet Metal chamfering | 6∼80 mm (On customer demand) |

Milling Angle of Top Milling unit | 0° to +45° |

Milling Angle of Down Milling unit | -45° to 0° |

Edge Milling Speed | 150∼1000 mm/min. Stepless |

High Speed of Idle | 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200 For delivery) |

Quantity of Hydraulic Jacks | 12 pieces |

Quantity of Mechanical Manual Jacks | 12 pieces |

Quantity of Hydraulic Jack Screw | 6 sets, intermittently installed |

Worktable Width | 650 mm |

Worktable Height | 1050 mm |