A. Applicable Range of 6 Axis 1400/12 High Precision Plasma Oxy-fuel CNC Pipe Intersection Cutting machine:

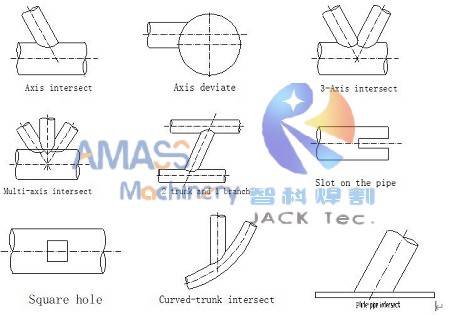

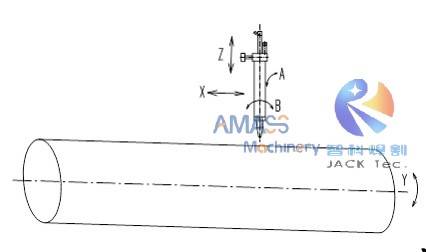

1. Control Complication: With 6 control axis active in CNC control system, this equipment is a set of High Precision CNC Pipe Cutting Machine. The bevels, chamfers on any position of workpiece pipe that can be machined in this CNC Pipe Intersection Cut machine is illustrated in attached sketch and below: (Fig.1)

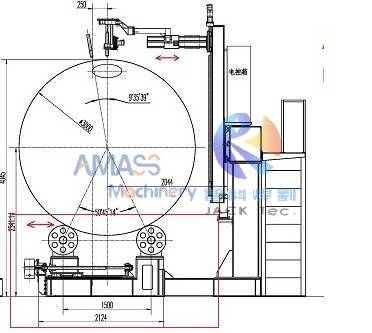

2. Pipe Diameter: The model of 6 Axis 1400/12 Flame and Plasma High Precision CNC Pipe Intersection Cut Machine is the middle sized version, in CP series CNC Pipe Cutting Machine: The max. diameter of pipe applicable for the equipment is Φ1400 mm, which is the most common selected size range of application on pipe cutting and chamfering in industry.

B. Technical View on 6 Axis 1400/12 High Precision Plasma Oxy-fuel CNC Pipe Cutting Machine:

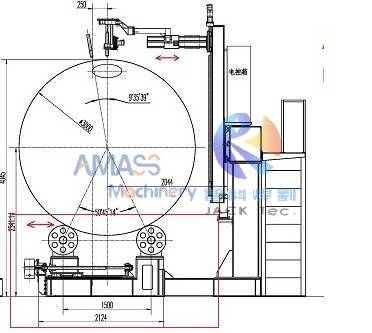

1. The Difference between 6 Axis and 7 Axis in Control System of High Precision CNC Pipe Intersection Cutting Machine: (Fig.2)

1) Shown in the above illustration, the axis removed from the 7 Axis CNC Pipe Cutting Machine, for turned into 6 Axis is W Axis: It is for adjustment on lateral movement of turning rolls along radial way of pipe. Please check the red color arrow in the above sketch;

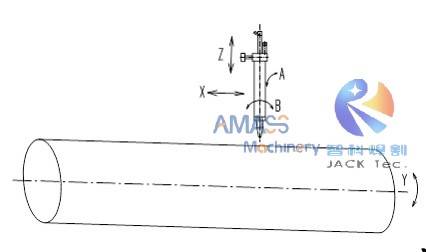

2) For illustration on 7 control Axis in CP series 7 Axis High Precision Plasma Oxy-fuel CNC Pipe Intersection Cutting Machine, it can be identified from below sketch on 5 Axis CNC Pipe Cutting Machine, together with the V axis of torch lateral movement: (Fig.3)

2. Why Remove W Axis in Plasma Oxy-fuel CNC Pipe Cutting Machine for Pipe Diameter Range of 1400mm?

1) The reason is, because of the relatively small diameter of workpiece pipe (Φ300mm ~ Φ1400mm), compared with larger range of Φ600mm~ Φ3000mm, controlling span of turning rolls in this direction is difficult and of little significance, for operation of the middle size range Plasma Oxy-fuel CNC Pipe Intersection Cutting Machine;

2) Meanwhile, the V Axis of cutting torch movement along radial direction of pipe is kept, which means precise manipulation of cutting and beveling operation can be fully guaranteed in the CNC Pipe Cutting Machine;

3. How to Determine Proper Control Axis for “Complicated” Plasma Oxy-fuel CNC Pipe Cutting Machine?

In general, for CP series CNC Pipe Cutting machine, the applicable “complicated” version is:

1)7 Axis is suitable for medium to large range of workpiece: The corresponding max. pipe diameter is 2000 mm and above: It is CNC CP 2000/2500/3000 models of High Precision Plasma Oxy-fuel CNC Pipe Intersection Cutting Machine;

2) 6 Axis is suitable for small to medium range of workpiece: The corresponding max. pipe diameter is less than 2000 mm: It is CNC-CP 600/1400models of High Precision Plasma Oxy-fuel CNC Pipe Intersection Cutting Machine.

C. Technical Parameters of 6 Axis 1400/12 High Precision Plasma Oxy-fuel CNC Pipe Intersection Cutting Machine:

Below is specification of the 6 Axis CNC-CP 1400/12 High Precision CNC Pipe Intersection Cut Machine:

Model Technical Parameter | 6 Axis CNC-CP 1400/12 High Precision Plasma Oxy-fuel CNC Pipe Cutting Machine |

Accommodating Diameter Range of Pipe (mm) | 300 ~ 1400 |

Accommodating Max. Length of Pipe (mm) | 12000 |

Accommodating Thickness Range of Pipe for Cutting (mm) | 6~100 mm for flame cutting 3 ~ 25mm for plasma cutting |

Accommodating Cutting Speed | 200∼800mm/min. for flame cutting Around 200~ 2000mm/min. for plasma cutting (Based on thickness of Pipe and Plasma Power) |

Cutting Speed Control Way | CNC Controller, servo motor and drive |

Active CNC Control Axis | 6 Axis of X/Y/Z/A/B/V X Axis: For cutting torch cut along workpiece length direction; Y Axis: For managing CW/CCW workpiece rotation; Z Axis: For cutting torch adjusted up and down; A Axis: For tilting cutting torch along workpieces radius; B Axis: For tilting cutting torch along workpiece length direction; V Axis: For cutting torch adjusted along workpiece length direction |