A. Usage and Applicable Workpieces in HJ Series BOX H Beam Horizontal Press Straightening Machine:

1. Function: HJ model BOX H Beam Lateral Straightening Machine is an important product branch of H Beam Straightening Machine, for performing straightening lateral deformation of H/ BOX Beam / Welding steel structure member along length direction;

2. Suitable Workpieces in Welding Structure Horizontal Press Straightening Machine:

1) Multi-Function: Unlike HYJ and YTJ series Flange H Beam Straightening Machine, which is specifically being applied for straightening H Beam flange deformation, this Horizontal Press Straightening Machine can be used on wide variety types of steel structure workpieces: H/ BOX Beam; Section Steel; Channels, etc.;

2) Deflected H Beam to be corrected in Steel Structure Beam Horizontal Press Straightening Machine: (Fig.1)

3) Wuxi JACK HJ250 BOX H Beam Horizontal Press Straightening Machine works on a piece of BOX Beam at customer facility: (Fig.2)

B. Model Selection and Operation on Welding Steel Structure BOX H Beam Lateral Straightening Machine:

1. Working Principle of HJ Series BOX H Beam Horizontal Press Straightening Machine:

1) Working Nature: This machine is in essence a kind of hydraulic drive Working Press;

2) Its acting unit is a piece of oil cylinder drive ram which moves in horizontal direction, pushing workpiece into plastic deformation of opposite direction, thus acquiring purpose of straightening;

3) Straightening Stroke Management: To precisely manage on lateral movement straightening stroke of the ram, there is a measuring ruler equipped in working unit of the machine, to control straightening volume on workpieces:

4) Hydraulic drive pushing ram in Horizontal Press Straightening Machine: (Fig.3)

5) Straightening stroke indicating ruler in BOX H Beam Lateral Straightening Machine: (Fig.4)

2. Operation on HJ Series Welding Structure Horizontal Press Straightening Machine:

1) Straightening Style: Correspondingly, in this length direction straightening machine, straightening is carried out in the form of step by step lateral pushing;

2) Which means, at the completion of current segment straightening, the workpiece is pushed forward manually for next segment straightening;

3) Workpiece Sending Forward: In this respect, although there are input and output conveyor to be equipped with the machine, its conveyors majority conditions work in the mode of manual acting, instead of motor drive. Especially its output conveyor;

4) Operation on Horizontal Press Straightening Machine is by means of operating pendent: (Fig.5)

3. Straightening Segment Length Adjustment in Welding Steel Structure BOX H Beam Lateral Straightening Machine:

1) Depending on length and cross section size of workpiece, the length of straightening segment in Horizontal Press Straightening Machine can be adjusted in the range of 1500mm to 2000mm;

2) This means, every time straightening action in the machine can fulfill 1500mm to 2000mm length of workpiece body;

3) The adjustment on this working zone length is realized with 2 pieces of holding points, which also serve as straightening force bearing points in the H Beam Straightening Machine:

4) Operating acting zone of Horizontal Press Straightening Machine: (Fig.6)

4. Standard and Common Models of Wuxi JACK Welding Structure Horizontal Press Straightening Machine:

1) The differentiation on models of BOX H Beam Lateral Straightening Machine is based on its max. output straightening force, from 20 ton (Model: HJ20) to 200 Ton (HJ300);

2) Other common used models include: HJ100/ HJ200/ HJ250;

3) Wuxi JACK HJ200 model Horizontal Press Straightening Machine at customer workshop: (Fig.7)

4) Wuxi JACK HJ300 Steel Structure Beam Horizontal Press Straightening Machine at Russian customer facility: (Fig.8)

C. Structure and Main Units in Welding Structure Horizontal Press Straightening Machine:

Composition: This BOX H Beam Lateral Straightening Machine is composed of mechanical main frame/ Input conveyor/ Output conveyor/ Hydraulic system and electric control system:

1. Mechanical Mainframe Assembly in Horizontal Lateral H Beam Straightening Machine:

1) The main components include: Stationary working bed/ Acting pressing beam/ Straightening use cylinder / Supporting roller tables;

2) Straightening drive cylinder is fixed onto horizontal beam. Its movement is guided with piston rod, during straightening pressing working period of the machine;

3) The 2 pieces of straightening force blocks are installed at front face of pressing beam. Its secured interval positions can be adjusted manually. This interval equals to single time straightening length in the Horizontal Press Straightening Machine. After adjustment, the 2 blocks are secured manually with screws;

4) To avoid conflict between workpiece and the 2 force blocks during workpiece sending in, there are 2 pieces of positioning cylinders equipped in the machine, which has 1335mm interval between each other. These 2 positioning cylinders can push workpiece away from the 2 force blocks when necessary;

5) Mechanical main frame of Wuxi JACK HJ300 BOX H Beam Horizontal Press Straightening Machine: (Fig.9)

2. Input and Output Conveyors of HJ Models Welding Structure Horizontal Press Straightening Machine:

1) Input and output conveyors are for sending in and out workpiece into and out of the machine respectively;

2) Both the conveyors consist of driving and idle roller tables;

3) Infeed and outfeed roller tables all have 8,000mm length;

4) Outfeed roller table is driven with motor reducer;

3. Hydraulic System in Steel Structure Beam Horizontal Press Straightening Machine:

1) Function: Hydraulic system is for pushing and clamping workpiece firmly;

2) Equipped with intake and pressure filters: One filter works during commissioning; The other filter manages on official running of the machine;

3) Main components of hydraulic system include: Pump station/ Straightening purpose and Positioning purpose cylinders/ hose;

4) Long service life: Equipped with fine filter, hydraulic system makes sure long term reliable running of the machine itself.

D. Primary Technical Parameters of Horizontal Lateral Acting Welding Steel Structure H Beam Straightening Machine:

1. Working Parts Specifications of Horizontal Press Straightening Machine:

Taking H Beam as Example:

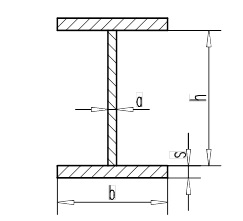

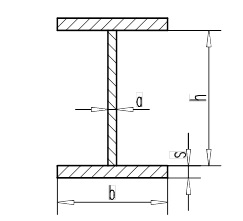

Suitable H Beam Sizes for Wuxi JACK HJ20~ HJ300 BOX H Beam Lateral Straightening Machine: (Fig.10)

1) Flange Width b: From (100 ~ 200 mm) for HJ20 to (200 ~ 800 mm) for HJ300

2) Flange Thickness s:From (6 - 15 mm) for HJ20 to (6 - 40 mm) for HJ300

3) Web Height h:From (100 – 400 mm) for HJ20 to (200 – 600 mm) for HJ300

4) Web Thickness a:From (5 – 7 mm) for HJ20 to (6 – 30 mm) for HJ300

5) H Beam Length: 3,000 – 12,000 mm

2. Main Technical Parameters of HJ Series BOX H Beam Horizontal Press Straightening Machine:

Models | HJ20 ~ HJ300 Welding Steel Structure BOX H Beam Lateral Straightening Machine |

Max. Straightening Pressure Force | 20 ~ 300 Ton (HJ20 ~ HJ300) |

Max. Straightening Hydraulic Cylinder Stroke | 350 ~ 800 mm (Can be special made) (HJ20 ~ HJ300) |

Hydraulic Station Driving Motor | 4 ~ 22 kW (HJ20 ~ HJ300) |

Hydraulic Station Rated Working Pressure | 12 ~ 25 MPa (HJ20 ~ HJ300) |

Input and Output Roller Table length | 8000mm * 2 |

Input and Output Roller Table Driving Motor | 1.5 kW *2 |

Total Weight of H Beam Straightening Machine | 3,200 kg ~ 12,000 kg (HJ20 ~ HJ300) |

Electricity Power Supply | 380V, 50Hz, 3P |