A. Function, Working Style and Capability of SXBJ-6 Double Heads Standard Sheet Metal Plate Edge Milling Machine:

1. Importance: The 6000mm edge milling stroke model SXBJ-6, is the typical and often selected product by customers, in the applicating realm of XBJ and SXBJ series Steel Plate Edge Beveling Machine;

2. Function of Double Heads SXBJ-6 Standard Sheet Metal Plate End Milling Machine:

1) Equipped with 2 sets of milling head, this standard model machine of edge chamfering can make welding groove on edges of workpiece steel plate, by means of the high speed revolutionary revolve of facer blade:

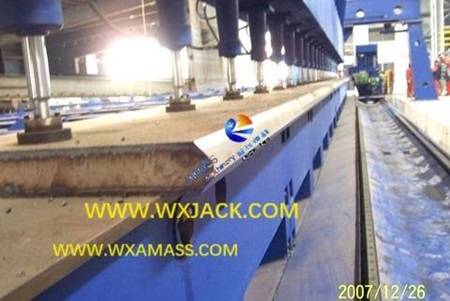

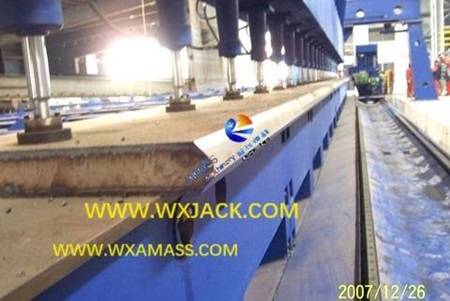

2) The glimpse on running of high standard quality facer blade in Wuxi JACK machine for steel plate edge chamfering: (Fig.1)

3) The two main advantages of double heads long stroke machine for metal plate edge milling are its capability of completing complicate welding groove, as well as high efficiency on edge grooving, which are illustrated in below segment;

3. Working Style and Capability of SXBJ-6 Double Heads Standard Sheet Metal Plate Edge Milling Equipment:

1) Work Style of SXBJ-6 Standard Sheet Metal Plate Edge Milling Machine:

With the configuration of two sets of milling head assembled,

a) One set of the milling head completes edge grooving on top and straight edges beveling on workpiece steel plate;

b) The other set of the milling head completes edge grooving on bottom edge beveling of workpiece steel plate;

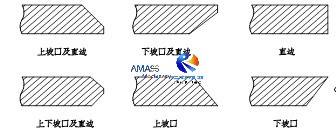

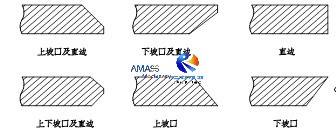

2) The finished upper, straight, bottom edge grooving, or, X type grooving, on edge of steel plate, produced from Wuxi JACK double heads Metal Plate Edge Milling Machine: (Fig.2)

3) The 6 types of most frequent selected grooves that can be delivered from standard models machine for sheet metal plate edge beveling : (Fig.3)

B. Application of SXBJ-6 Double Heads Standard Sheet Metal Plate End Milling Machine:

1. Extensive Use of SXBJ-6 Double Heads Edge Milling Machine:

1) The Normal Distribution of Statistics theory shows majority of metal plates for making welding groove have its size falling within the range of 1000mm to 6000mm, which matches perfectly with valid stroke of the SXBJ-6 standard model machine for sheet metal plate edge milling ;

2) This explains why SXBJ-6 equipment of edge milling has the most extensive application;

2. Great Contribution on Welding Preparation with Edge Beveling Machine:

With the various kinds of grooves made on edges of steel plate in XBJ and SXBJ series general purpose Sheet Metal Plate Edge Milling Machine, the workpiece steel plate can be performed with subsequent fabrication, with the ideal welding fusion and cover face;

3. Application Examples of XBJ and SXBJ models Standard Sheet Metal Plate Edge Chamfering Machine:

1) One of the examples is butt joint welding of steel plate:

2) The completed butt joint steel plate, which should be cut with beveled groove on edge of steel plate first: (Fig.4)

3) Longer stroke, such as SXBJ-18 large size model machine, are indispensable equipment applied in Shipbuilding Industry:

4) A set of Wuxi JACK SXBJ-18 Large scale Edge Milling Machine is installed and operated at an open air Shipbuilding facility: (Fig.5)

C. Structure and Function Division on SXBJ-6 Double Heads Standard Sheet Metal Plate Edge Chamfering Machine:

1. General View on XBJ and SXBJ Models Sheet Metal Plate Edge Milling Machine:

1) The attached 3rd and below picture show a local shot of Wuxi JACK SXBJ-6 standard model equipment for sheet metal plate edge milling at its operating side, or Rear side;

2) As an Edge Milling Equipment with structure of transverse gantry beam, the machine can be classified into and viewed as front side and rear side;

3) Operating side (Rear Side) of the Standard Sheet Metal Plate Edge Milling Machine: (Fig.6)

2. Front Side of XBJ and SXBJ Models Sheet Metal Plate End Milling Machine:

1) This side is for loading and unloading of workpiece steel plate into and out of the machine for edge milling operation;

2) There is a group of floor installing longitudinal racks with its extended depth in the range of 1000 mm to 3000 mm, for completing on assistant loading and unloading job of workpiece;

3) The workpiece loading and unloading side (Front side) of XBJ and SXBJ models machine for sheet metal plate edge milling: (Fig.7)

3. Back Side of XBJ and SXBJ Models Sheet Metal Plate Edge Beveling Machine:

1) This side is the operating side of the machine for sheet metal edge milling;

2) Two sets of edge milling units are assembled here, and operator works at this side also;

3) Operating side (Back side) of Sheet Metal Plate Edge Milling Equipment: (Fig.8)

D. Technical Parameters of SXBJ-6 Double Heads Standard Sheet Metal Plate Edge Milling Machine:

Model Technical Parameter | SXBJ-6 Double Heads Standard Sheet Metal Plate End Milling Machine |

Sheet Metal Plate Max. Edge Milling Length | 6,000 mm |

Sheet Metal Plate Max. Edge Milling Width | 3,000 mm |

Milling Head Quantity | 2 Sets |

Milling Angle Range of Top Milling Unit | 0° to +60° |

Milling Angle Range of Down Milling Unit | -45° to 0° |

Metal Plate Thickness Range for Sheet Metal Edge Chamfering | 6∼50 mm (Based on customer demand) |

Quantity of Hydraulic Jacks | 10 Pieces |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Milling Unit Feeding Motor | 2.2 kW |

Edge Milling Speed | 130∼1000 mm/min. (VFD, A.C. Inverter Control) |

High Speed of Idle | 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200mm When making delivery) |

Hydraulic Rated Pressure | 5.5 MPa |

Hydraulic Working Pressure | 3.5 MPa |

Hydraulic System Flowrate | 47 L/min. |

Worktable Width | 550 mm |

Worktable Height | 1050 mm |