A. When to Use 3 Axis 2000/12 High Efficiency Thermal Gas CNC Pipe Intersection Cutting Machine?

1. The 3 Axis 2000/12 Flame and Plasma CNC Pipe Cutting Machine is middle size and simple control model, among all products in CP series CNC Pipe Cut Equipment:

1) Developed following the earliest models of Φ1400mm specification product and Φ3000mm specification product, the Φ2000mm specification High Efficiency CNC Pipe Cutting Machine bridges the gap for this common used diameters of pipe/ tank in Manufacturing Industries;

2) To be specific, this model of 3 Axis 2000/12 CNC Pipe Cutting Machine is for implementing fixed length cut and hole cut on the pipes, with max. Φ2000mm diameter and 12m length. It is not an often selected model, which belongs to one of the member products in family of CP series Plasma Oxy-fuel Thermal Gas CNC Pipe Cutting Machine:

A piece of Φ2000mm carbon steel pipe was being cut in the Wuxi JACK 3 Axis 2000/12 CNC Pipe Cutting Machine: (Fig.1)

2. This model of 3 Axis 2000/12 High Efficiency CNC Pipe Cut Equipment has similar structure, controlling and operation with other models of CNC Pipe Intersection Cutting Machine. The difference mainly involve control axis and dimensions of parts and components.

B. The 3 Axis and 5 Axis Analysis on High Efficiency Thermal Gas CNC Pipe Cutting Machine:

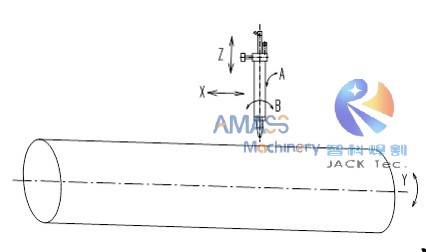

Below is the sketch indicating 3 axis and 5 axis applied in CNC Pipe Intersection Cutting Machine: (Fig.2)

1. As can be found from above, the main difference between 3 axis and 5 axis CNC Pipe Intersection Cutting Machine lies at:

1) A Axis: Cutting torch traverse swing along pipe radial direction;

2) B Axis: Cutting torch longitudinal swing along pipe axial direction;

These 2 controlling axes are for managing tilting angle of cutting torch when make slant face grooving, and are only available at the 5 Axis and 7 Axis models of the CNC Pipe Intersection Cutting Machine;

2. Comparatively, these 3 axes are for fundamental and indispensable control, embedded at all the models of CNC Pipe Cutting Machine:

1) Horizontal X Axis: Cutting torch longitudinal travel in pipe axial direction;

2) Revolving Y Axis: pipe revolving axis;

3) Vertical Z Axis: This axis is controlled with CNC individually during operation of the CNC Pipe Cut Equipment, not inter-connected with other axis of the machine;

These 3 axis fulfil basic task of Thermal Gas CNC Pipe Intersection Cutting Machine, being equipped at all models of 3 Axis, 5 Axis and 7 Axis product.

C. Complement on Model of 3 Axis 2000/12 Thermal Gas High Efficiency CNC Pipe Intersection Cutting Machine:

1. The Meaning of “/12” in the Model of CNC Pipe Cut Equipment:

1) Here the “/12” in the CNC Pipe Cutting Machine model indicates it can cut workpiece pipes of max. 12m long;

2) This is the largest specification in standard models of CNC Pipe Cutting Machine: The other 2 standard optional specifications are “/6” for 6m length, and “/9” for 9m respectively;

3) This specification can be determined by customers, when selecting proper configuration of the Thermal Gas CNC Pipe Cutting Machine;

2. Future Expansion on 3 Axis 2000/12 Thermal Gas CNC Pipe Intersection Cutting Machine:

1) For workpiece pipes sizes of Φ1500mm to Φ2000mm, the models of 5 Axis and 7 Axis CNC Pipe Intersection Cutting Machine are more welcomed, because of beveling capability;

2) So, at Wuxi JACK, the design and manufacture of 3 Axis 2000/12 High Efficiency CNC Pipe Intersection Cutting Machine are made in the form of modular, which is considered for convenience of future expansion, in case of necessary for customers demand.

D. Technical Parameters of 3 Axis 2000/12 High Efficiency Thermal Gas CNC Pipe Cutting Machine:

Below is specification of 3 Axis 2000/12 Flame and Plasma High Efficiency CNC Pipe Cut Equipment:

Model Technical Parameter | 3 Axis CNC-CP 2000/12 High Efficiency Thermal Gas CNC Pipe Intersection Cutting Machine |

Suitable Diameter Range of Workpiece Pipe (mm) | 400 ~ 2000 |

Suitable Max. Length of Workpiece Pipe (mm) | 12000 |

Suitable Thickness Range of Workpiece Pipe (mm) | 6~100 mm for flame cutting; 3 ~ 25mm for plasma cutting |

Thermal Gas Cutting Speed | 200∼800mm/min. for flame cutting Around 200~ 2000mm/min. for plasma cutting (Based on thickness of Pipe and Plasma Power) |

Adopted CNC Control Axis | 3 Axis of X/Y/Z: X Axis: For Pipe length cutting; Z Axis: For fitting pipe diameter change; Y Axis: For pipe rotating |