A. Uniqueness of XBJ-6 Beyond Capacity Sheet Metal Plate Edge Milling Machine:

1. The most distinguished feature with XBJ-6 single head model machine of this product section is, it has the capability on edge milling steel plate exceeding nominal specification;

2. For example, here XBJ-6 refers to the max. edge milling stroke of 6000mm. In reality, the equipment has actual the largest edge milling stroke of 9000mm;

3. This is the reason why we name it “Beyond Capacity” Edge Milling Machine.

B. Configuration and Main Specification of Beyond Capacity Sheet Metal Plate Edge Beveling Machine:

1. Mechanical Main Frame of the XBJ-6 Sheet Metal Plate Edge Milling Machine:

1) The secret of such exceeding edge milling stroke lies in mechanical structure of machine mechanical main body. Let us make a comparison as below:

2) Mechanical frame of XBJ-6 beyond capacity model machine: (Fig.1)

3) Mechanical frame of “Ordinary Conventional” Sheet Metal Plate Edge Milling Machine: (Fig.2)

4) For this set of XBJ-6 model machine, it has 6000mm length working table length;

2. Milling Unit of the XBJ-6 Sheet Metal Plate Edge Chamfering Machine:

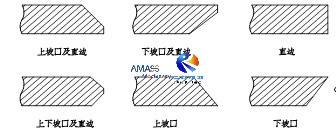

1) Like all the other products of XBJ and SXBJ series Edge Milling Machine, this XBJ-6 model equipment also has capability of completing steel plate chamfering into following kerfs:

2) The cutting kerfs serving as welding grooves on edges of workpiece, produced from XBJ-6 model machine: (Fig.3)

C. Mechanical Machine body of XBJ-6 Beyond Capacity Sheet Metal Plate Edge Milling Machine:

As can be found from the attached first to third pictures, and illustration figure 1 and 2 as above, this Edge Milling Machine has upgraded style of machine body, which is different from that of the routine models machine:

1. Mechanical Structure of Conventional Edge Milling Machine:

It has open structure machine body of gantry beam and working table, shown as below:

1) Open structure mechanical body of conventional structure SXBJ-12 model: (Fig.4)

2) Which means, there is no restriction on movement of the milling unit carriage along working table of the machine during work;

3) The milling head carriages can stand at lateral side of machine work table, beyond reach of the machine body when not in working;

2. Mechanical Structure of Beyond Capacity XBJ-6 Edge Milling Machine:

Comparatively, on the contrary, this special model machine has half enclosed mechanical structure:

1) The half close mechanical frame of the XBJ-6: (Fig.5)

2) As can be observed from the above photo, there are wall boards at both sides of the Edge Milling Machine gantry beam and worktable, which extend in the direction 90° perpendicular to the gantry beam and worktable, at the side fitting the milling unit;

3) In this way, movement of the milling unit in the machine is confined within this area;

4) The total length of the machine mechanical body is 700mm longer than that of the routine models, considering width of the 2 pieces of wall boards;

3. Advantages of Half Closed Mechanical Frame for XBJ-6 Edge Milling Machine:

1) The reason on such design is, the machine can have more than 6000mm steel plate chamfering, because of the dent orifice cut at the junctions between the wall boards and worktable at both sides;

2) The opening at the lateral side of Edge Milling Machine worktable: (Fig.6)

3) With this opening, the steel plate can extend thru the orifice. Hence in the process of Edge Milling operation, with the manipulation of the workpiece leftward and rightward, edge milling steel plate of more than 6000mm can be got;

4) Such kind of design has another advantage that, the machine body gets more firmness. Of course, that does not mean the mechanical body of conventional models machine is not strong enough. All of our products have reasonable design and qualified manufacturing process, which is eligible for completing on its duty reliably and consistently;

5) The downside of this design is it brings up manufacturing cost of the Sheet Metal Plate Edge Chamfering Machine. In all, which choice to make is a compromise, that which factors weights heavier: Longer stroke from Machine , or higher manufacturing cost of the machine.

D. Technical Parameters of XBJ-6 Beyond Capacity Sheet Metal Plate Edge Milling Machine:

Model Technical Parameter | Beyond Capacity XBJ-6 Single Head Sheet Metal Plate Edge Milling Machine |

Max. Plate Edge Milling Length | 6,000 mm (9,000mm can be got) |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Milling Unit Feeding Motor | 2.2 kW |

Milling Head Quantity | 1 set |

Plate thickness for Sheet Metal Chamfering | 6∼50 mm (On customer demand) |

Milling Angle of Top Milling unit | 0° to +45° |

Edge Milling Speed | 130∼1000 mm/min. (VFD, Inverter Control) |

High Speed of Idle | 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200 For delivery) |

Quantity of Hydraulic Jacks | 9 pieces |

Hydraulic Rated Pressure | 5.5 MPa |

Hydraulic Working Pressure | 3.5 MPa |

Hydraulic System Flowrate | 47 L/min. |

Worktable Width | 1450 mm (Including Wall Board) |

Worktable Height | 1050 mm |