A. The Characteristics of SXBJ-3 Tandem Sheet Metal Plate Edge Milling Machine:

1. Shown in the attached first photo, the 2 sets of SXBJ-3 model machine for metal plate beveling are arranged and operated as an integral group, running in an independent working zone;

2. This is the reason we named it “Tandem Metal Plate Edge Milling Equipment”;

3. Why Have Such Arrangement on Tandem SXBJ-3 Metal Plate End Milling Machine:

1) The 2 sets of equipment of metal plate groove making are for working in a group of heavy duty large scale Production Line, which produces stiffener assembling unit in a famous Chinese Port Machinery Company;

2) The 2 sets of the equipment here working in pair are installed at the second working station;

3) The first work station of production line is CNC Strip Plate Cutting Machine, for the purpose of steel plate cut;

4) Following that, the next step--- SXBJ-3 model tandem machine of edge milling, is for milling on welding groove at both sides of the steel plates, during the process of steel plates sending forward. This is why we name it Metal Plate Groove Making Equipment;

a) The tandem SXBJ-3 model machine in the production line: (Fig.1)

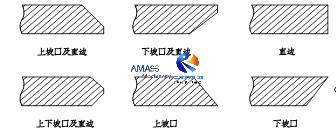

b) The welding grooves made with the tandem SXBJ-3 model equipment for metal plate groove making: (Fig.2)

5) Here, with the 2 sets of machine standing in a row in the direction of steel plates sending through. The steel plates can have edge milled on its both sides in a flow, one set of machine responsible for one edge of steel plate, without the necessity of being turned around;

6) At the completion of such metal plate edge milling processing, the steel plate will be sent to subsequent stations: Edge Rounding Machine for steel plate edge trimming and rounding; Welding Robots for fabricating into stiffener plate; Stiffener Plate Element Straightening Machine for flattening. Among these the RH3000 Edge Rounding Machine and J28 Plate Element Straightening Machine are also delivered by our Wuxi JACK for customer.

B. Coordination Work between the 2 sets of SXBJ-3 Metal Plate Beveling Machine:

1. It is not so simple that the 2 sets of the machines for edge milling just to be installed together. Instead, there should be strict cooperation and teamwork between the two sets of machines:

2. As can be observed from below photo, a group of rollers in the form of rocking arm are installed at the enclosed area between the two sets of machines, for the purpose of conveying the steel plate going through this section;

The 2 sets of Metal Plate Edge Milling Machine with roller table in between: (Fig.3)

3. Working Logic of SXBJ-3 tandem Metal Plate Edge Milling Equipment:

1) When the Edge Milling Machine are not in working and be ready for metal plate edge milling, the roller arms fall down, and serve as conveyor of the workpiece for its transportation and positioning;

2) When either of the machine for edge milling is in the state of making welding groove, the roller arms raise to leave space for milling unit operation. Please check attached 2nd picture and below;

The roller table raises to support End Milling Machine in operation: (Fig.4)

4. Such layout of the Metal Plate Beveling Machine has no restriction on length of the workpiece to be edge milled, because there is sufficient length of conveyor at both external sides of this tandem machines for edge milling, and the working zone in between.

C. Specification of the Two sets of SXBJ-3 Metal Plate Edge Milling Machine:

The two sets of SXBJ-3 model machines for metal plate end milling are standard type: Each set is equipped with two sets of 7.5kW milling units with facing head installed, for fulfilling the max. valid edge milling stroke of 3000mm.

D. Technical Parameters of Tandem SXBJ-3 Sheet Metal Plate Edge Milling Machine:

Model Technical Parameter | Tandem SXBJ-3 Double Heads Metal Plate End Milling Machine |

Max. Plate Edge Milling Length (mm) | 3,000 / Set |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm / Set |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel / Set |

Hydraulic Power Motor | 5.5 kW / Set |

Milling Unit Feeding Motor | 2.2 kW / Set |

Milling Head Quantity | 2 sets / Set |

Plate thickness for Sheet Metal chamfering | 6∼40 mm (On customer demand) / Set |

Milling Angle of Top Milling unit | 0° to +80°/ Set |

Milling Angle of Down Milling unit | -60° to 0°/ Set |

Edge Milling Speed | 130∼1000 mm/min. (Inverter Control) |

High Speed of Idle | 4000 mm/min. |

Quantity of Hydraulic Jacks | 7 pieces / Set |

Hydraulic Rated Pressure | 5.5 MPa / Set |

Hydraulic Working Pressure | 3.5 MPa / Set |

Worktable Width | 450 mm / Set |

Worktable Height | 1050 mm / Set |