A. Outline on FXBJ-21 Large Plate Edge Milling Machine:

The FXBJ-21 model large machine for plate beveling of this product section is the enlarged and complicated version, in the product group of “normal and conventional” gantry fixing style machine for edge milling on sheet metal.

B. The Special Structure, Configuration and Overall Dimension of FXBJ-21 Large Plate Edge Grooving Machine:

1. Special Structure of the FXBJ-21 Large Plate Edge Milling Machine:

1) Longitudinal Movable Gantry: Please check attached pictures. Gantry of this FXBJ-21 Large Plate Edge Milling Machine can be moved along longitudinal direction, which means in the direction perpendicular to the gantry itself, within the stroke of 1000 mm;

2) 4 sets of symmetric installed milling cutter: There are four sets of milling cutters in total fitted with this large machine for edge milling on steel plate, each piece of milling cutter has its individual moving carriage, and arranged in symmetry along both sides of the working table of the large machine for fulfilling edge milling task;

3) In this way, workpiece can be processed with making welding groove by means of edge milling steel plate on its both sides edges of the Large Edge Milling Machine, in the form of top/ bottom/ straight/ slant bevels / chamfers / edges with one time stroke of milling cutters;

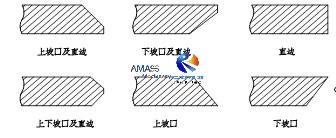

Welding grooves that be beveled with Plate Edge Grooving Machine: (Fig.1)

2. The Grander Overall Dimension of the FXBJ-21 Large Plate Beveling Machine:

1) With additional degree of freedom added with the gantry along longitudinal way, dimension of the workpiece to have plate edge beveling with this machine for plate beveling edge milling grows bigger also;

2) Workpieces of up to (21m Length x 1,200mm Width) is available to have machining of plate end beveling on this large machine of edge milling;

3) This FXBJ-21 model large machine of plate edge milling has total length of around 29m, width 2,800mm, and height 3,800mm;

3. Configuration of the FXBJ-21 Large Plate Edge Milling Machine:

1) Each of the milling carriage has its own control board and operating panel;

2) The central control cabinet and operating panel of the large machine of edge milling is installed at lateral side of moving gantry.

C. Usage and Performance of the FXBJ-21 Large Steel Plate Edge Milling Machine:

1. Application of the FXBJ-21:

This heavy duty machine for edge milling on sheet metal is a tailor made product we designed and produced for a famous Port Machinery customer in China, for their manufacture of Ribbed Plate Element of big size in a production line;

2. Task of the FXBJ-21 Large Plate Edge Milling Machine:

1) For the purpose of efficient and high quality welding on long slit plates cut with Strip Plate Cutting Machine, these big size raw materials need to be done with first step of making welding groove;

2) Both sides, upper and lower edges, high efficiency. Hence the demand on this large machine of edge milling, and it is also the reason why we name it Large Plate Edge Grooving Machine;

3. As can be observed from the attached pictures, gantry of this large machine of plate edge milling is supported and guided with strong and sturdy triangular brackets at its both ends, making surefire running of the entire machine;

4. Hydraulic JACKs in FXBJ-21 Large Steel Plate Edge Milling Machine:

1) Clamping of the workpiece during work of the machine for edge milling on large steel plate is by means of hydraulic JACKs;

2) These hydraulic JACKs are installed at the bottom surface of pressing beam, with its quantity varied based on stroke of each model, from 6 pieces for XBJ-3 model machine, to 24 pieces for SXBJ-18 large model machine;

3) For this set of FXBJ-21 large model Edge Milling Machine, it is equipped with 35 pieces of hydraulic jacks.

D. Technical Parameters of FXBJ-21 Large Plate Edge Milling Machine:

Model Technical Parameter | Large Gantry Longitudinal Moving FXBJ-21 Four Milling Heads Steel Plate Edge Milling Machine |

Max. Plate Edge Milling Length | 21,000 mm |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm (Higher Power available) |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Taper Hole of Milling Spindle End | ISO 50 (7:24) |

Spindle rpm | 75 ~ 420 r/min. |

Spindle Stroke | 100 mm |

Milling Head Quantity | 4 sets |

Plate thickness for Sheet Metal chamfering | 6∼80 mm (On customer demand) |

Milling Angle of Top Milling unit | 0° to +45° |

Milling Angle of Down Milling unit | -45° to 0° |

Edge Milling Speed | 150∼1000 mm/min. Stepless controlled with Inverter |

High Speed of Idle | 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200 For delivery) |

Quantity of Hydraulic Jacks | 35 pieces |

Quantity of Hydraulic Jack Screw | 9 sets, intermittently installed |

Worktable Width | 2800 mm |

Worktable Height | 1050 mm |

Machine Overall Dimension | 29 m Length x 2.8m Width x 3.8m Height |