A. Importance and Scope of SXBJ Series Coupling Heads General Purpose Steel Plate Edge Milling Machine:

1. Predominance Position: Coupling Heads, or SXBJ models double heads Automatic Steel Plate Welding Groove Producer is the main stream product, which takes up over 50% of practical business cases, in the applicating field of XBJ and SXBJ series General Purpose Steel Plate End Milling Machine;

2. Range of SXBJ Models General Purpose Steel Plate End Grooving Machine:

1) SXBJ models double heads Motorized Steel Plate Edge Beveling Equipment covers full range of available edge milling stroke in the market, from 3,000mm to 18,000 mm.;

2) The corresponding models of the Welding Groove Producer are SXBJ-3 and SXBJ-18 double heads machine of edge milling respectively. Please compare below 2 photos:

3) Wuxi JACK SXBJ-3 model double heads machine for end milling on steel plate: (Fig.1)

4) Wuxi JACK SXBJ-18 Double Heads large scale Motorized Steel Plate Edge Beveling Equipment: (Fig.2)

B. Function and Technical Characteristics of SXBJ Models Double Heads Welding Groove Producer:

1. Types of Welding Grooves Produced from SXBJ Series Double Heads Steel Plate End Milling Machine:

1) The most conspicuous advantage of SXBJ double heads machine for plate end grooving is its high efficiency and full function;

2) This powerful Welding Groove Producer has capability of making all types of welding grooves, by means of one time working stroke of its two sets of edge milling carriages, along the working table of the machine;

3) All the common X/ Y/ V/ K types of chamfers can be finished on upper and lower edges of workpiece steel plate simultaneously, from these double heads machine for edge milling job, in the form of straight/ slant/ blunt edges beveling. Please check below photos:

4) Design sketch on 6 types of up and lower edges beveling: (Fig.3)

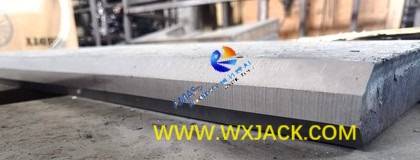

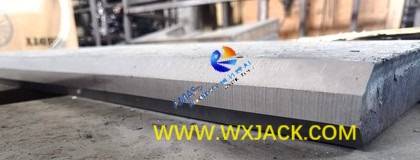

5) The actual finished superior quality welding grooves, on up/ bottom/ straight edges of steel plate, produced from Wuxi JACK SXBJ-125 model double heads End Milling Machine: (Fig.4)

6) In this way, SXBJ models double heads equipment for edge beveling echoes the trend of higher productivity in today’s manufacturing industries. This is the basic reason on popularity of SXBJ series double milling heads machine;

2. Structure and Milling Heads Carriages Assembling in SXBJ Double Heads Steel Plate End Grooving Machine:

1) To attain the outcome of the abovementioned welding grooves, in all the products of SXBJ series double milling heads machine, the two sets of milling heads are assembled in the way of:

2) The leading one piece of milling head carriage is responsible for making beveling on top and straight edges of workpiece steel plate;

3) The following 2nd piece of milling head carriage is for making beveling on bottom edge of the steel plate. Please check attached two pictures and below photos for comparison:

4) The installation orientation of the 2 sets of milling head carriages, in Wuxi JACK SXBJ-4 model Double Heads steel plate Edge Milling Machine: (Fig.5)

3. Working Style of SXBJ Series Double Heads Steel Plate End Milling Machine:

1) The two sets of milling heads carriages work in pair, and move along working table of the double milling heads machine for steel plate end grooving;

2) In other words, the 2 sets of milling head carriage move in the identical working speed for implementing edge milling operation, which is controlled with inverter, and displayed in digital meter real time, delivering ideal finished bevels and chamfers, from the SXBJ models product of Welding Groove Producer machine;

3) Working speed control and display, during running of Wuxi JACK double milling heads machine for end grooving on steel plate: (Fig.6)

4) Another application of SXBJ models double heads Steel Plate End Grooving Machine:

a) The two sets of milling heads work separately, making metal plate edge milling on two separate pieces of workpieces respectively;

b) This is usually performed on large size (And hence long working stroke) the machine for steel plate end milling, such as from SXBJ-12 to SXBJ-18.

C. Classification on Welding Groove Producer SXBJ Double Heads Steel Plate End Milling Machine:

1. Conventional Single Side Type Double Heads Steel Plate Edge Milling Machine:

1) Most majority of SXBJ models double milling heads machine for end grooving on steel plate has its two sets of milling heads distributed at the same side of machine work table;

2) This is for the purpose of producing welding grooves on up and lower edges of steel plate, in the form of upper and lower edges beveling and chamfering, completed from one time edge milling operation, carried out in the double heads steel plate Edge Beveling Equipment. Please check below photo:

3) Wuxi JACK SXBJ-16 Conventional Single Side double milling heads machine: (Fig.7)

2. Special Two Sides Type Double Heads Steel Plate End Grooving Machine:

1) Besides, under certain circumstances, customers of Welding Groove Producer ask for both sides working table arrangement of milling units in the machine, for carrying out edge milling work;

2) Which means, one piece of milling unit carriage is installed at one side of the machine work table respectively. Please check below photo:

3) Wuxi JACK SXBJ-12 Special Two Sides double heads Steel Plate End Grooving Machine: (Fig.8)

4) This is for the purpose of fulfilling sheet metal edge milling on both sides of workpiece steel plate at the same time. Here, workpiece steel plate has narrow width of 500~ 600mm;

5) For more detail, please check corresponding product section of “Special made SXBJ-12 Double Heads Steel Plate Edge Milling Machine”.

D. Technical Parameters of SXBJ Series Double Heads Welding Groove Producer Machine:

Model Technical Parameter | Double Heads SXBJ Series General Purpose Steel Plate End Milling Machine |

Sheet Metal Plate Max. Edge Milling Stroke | 3,000 ~ 18,000 mm |

Sheet Metal Plate Width Range | 600 ~ 3,000 mm |

Sheet Metal Plate Thickness Range for Edge Milling | 6∼40/50/60/80 mm (Based on customer demand) |

Milling Head Quantity | 2 Sets |

Beveling Angle Range of Up Milling Unit | 0° to +90° |

Beveling Angle Range of Lower Milling Unit | -45° to 0° |

Quantity of Hydraulic Jacks | (8~ 30) pieces for (SXBJ-3 ~ SXBJ-18) |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm (Higher Power available) |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Milling Unit Traveling Motor Power | 2.2 kW |

Milling Unit Lifting Motor Power | 0.75 kW |

Milling Unit Tilting Motor Power (Optional) | 0.4 kW |

Taper Hole of Milling Spindle End | ISO 50(7:24) |

Spindle Stroke | 100 mm |

Edge Milling Operating Speed | 150 ∼1000 mm/min. VFD (Variable frequency drive) Stepless controlled with inverter |

Idle High Moving Speed of Milling Head Carriage | Constant 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200 For delivery) |

Quantity of Hydraulic Jack Screw | (2~8) sets, intermittently installed |

Worktable Length | (9~ 24) m |

Worktable Width | (450 ~ 550) mm |

Worktable Height | 1050 mm |