A. Purpose and Strong Points of Welding Aiding Equipment SXBJ-12 Long Stroke Sheet Metal Plate Edge Milling Machine:

1. Purpose of SXBJ-12 Sheet Metal Plate End Milling Machine:

1) Function: This equipment for sheet metal plate edge milling has two sets of 7.5kW milling units and corresponding individual motorized moving carriages, fulfilling up to 12,000mm linear stroke for producing welding grooves on edges of sheet metal plates;

2) Importance: SXBJ-12 model double heads large Edge Milling Machine is an indispensable Sheet Metal Plate Welding Aiding equipment for customers, who have demand on production process of metal plate welding in all sizes;

3) Working Moment: Wuxi JACK SXBJ-12 model machine is milling on up edge groove on workpiece steel plate: (Fig.1)

2. Welding Grooves Produced from SXBJ-12 Welding Aiding Equipment:

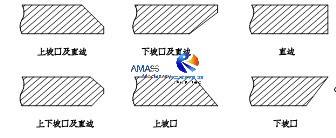

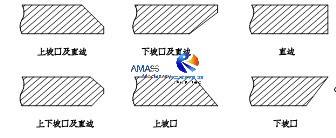

1) For achieving metal plate edge milling task, there are several types of chamfers to be made in SXBJ-12 general purpose Edge Milling Machine: Top bevel, bottom bevel, straight edge, slant edge. Examples are shown as below:

2) The X/ K / V types Up and Lower edges grooves made from SXBJ-12 model machine: (Fig.2)

3) As can be observed from the above illustration, the finished groove angle can be managed in the machine. This is realized by manual or motorized turning on milling head into target angle. Please check attached the 5th photo and below:

4) Tilted milling head and its running in Wuxi JACK SXBJ-12 End Milling Machine: (Fig.3)

3. Strong Points of SXBJ-12 Sheet Metal Plate Welding Aiding Equipment:

1) Daily Operation: It has safe, easy, high efficient and reliable operation;

2) Finished Quality: The completed edge grooves has high standard and consistent quality:

The superior quality chamfered steel plate machined from Wuxi JACK SXBJ-12 equipment: (Fig.4)

3) Management: Daily service and maintenance are convenient and low cost;

4) Machine Investment: Compared with Edge Planning Machine, XBJ and SXBJ series Edge Milling Machine can deliver same grade of welding groove, but with much lower Sheet Metal Plate Welding Aiding Equipment investment budget.

B. Technical Summary on SXBJ-12 Sheet Metal Plate Welding Aiding Equipment:

1. Maintaining Consistent Performance of Long Stroke Grooving in SXBJ-12 Edge Milling Machine:

1) In the Order to Delivery value chain of double heads long stroke machine for plate edge milling, one of the challenges comes from maintaining its consistency and uniform in terms of welding groove linearity and high precision;

2) Wuxi JACK Measures on Developing Sheet Metal Plate End Milling Machine:

For achieving this purpose, Wuxi JACK engineering team adopts series of measures to get the object met:

a) NPI (New product introduction), design, validation and quality assurance of the machine;

b) Strict management throughout production circle of the machine;

c) Installation and commissioning at customer site, as well as after sale service on this equipment;

2. Applicable Chamfering Angle Range in SXBJ-12 Sheet Metal Plate Edge Milling Machine:

1) The two sets of milling heads in machine are responsible for cutting out upper and straight edge beveling, together with bottom edge beveling respectively;

2) Under standard technical specifications, both the two milling heads have its tilting angle range of 0°~ 45°. See below photo:

3) The 0°~ 45° milling head equipped in Wuxi JACK Edge Milling Machine: (Fig.5)

4) Under special requirement from customers, the milling head responsible for making top and straight edges beveling can be tilted to 80° or even 90°. See below photo:

5) The 0°~ 80° milling head equipped in Wuxi JACK equipment for plate welding aiding : (Fig.6)

6) For the milling head of bottom edge beveling, due to its size, this milling head will collide with machine bed of the equipment, suppose wider range beyond 45° is tilted. So, in case of bottom edge beveling of 45° plus angle, our suggestion is to flip the metal plate 180° to make it upside down, and being loaded into the machine for edge milling operation again;

3. Control System of SXBJ-12 Sheet Metal Plate Edge Milling Machine:

1) Based on its working traits, control system of XBJ and SXBJ models general purpose machine for sheet metal edge milling is in the mode of “Central control and Separate arrangement”;

2) The core element is inverter, which controls speed of edge milling steel plate during the Plate Welding Aiding Equipment in operation;

3) Cables in the machine are deployed in the manner of Cable Slides, shown in the attached 4th photo and below:

4) The cable slides assembled onto Wuxi JACK SXBJ-12 machine for edge milling mechanical base bed: (Fig.7)

5) Electric Control Cabinet:

There are three pieces of control boards equipped in one set of the SXBJ-12 model machine:

a) One piece of the control board is responsible for general control on the machine, and installed at terminal of mechanical body of this large equipment;

b) The other two pieces of control board are for controlling each of the milling unit respectively, and installed on the two sets of milling carriages. See below photo:

c) The distribution of control boards in Wuxi JACK SXBJ-12 model machine for sheet metal plate end milling: (Fig.8)

C. Technical Parameters of SXBJ-12 Sheet Metal Plate Welding Aiding Equipment Edge Milling Machine:

Model Technical Parameter | SXBJ-12 Double Heads Sheet Metal Plate End Milling Machine |

Max. Metal Plate Edge Milling Stroke | 12,000 mm |

Width Range of Metal Plate | 600 ~ 3,000 mm |

Thickness Range of Metal Plate | 6∼80 mm (Based on customer demand) |

Quantity of Hydraulic Drive Jacks for Clamping Metal Plates | 18 Pieces |

Milling Head Quantity | 2 Sets |

Angle Range of Top and Straight Edge Milling Unit | 0° to +80° |

Angle Range of Bottom Edge Milling Unit | -45° to 0° |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Milling Unit Feeding Motor | 2.2 kW |

Edge Milling Working Speed | 130∼1000 mm/min. (VFD, Inverter Control) |

Idle High Speed of Milling Units | Constant 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200mm For delivery) |

Hydraulic Rated Pressure | 5.5 MPa |

Hydraulic Working Pressure | 3.5 MPa |

Hydraulic System Flowrate | 47 L/min. |

Worktable Width | 550 mm |

Worktable Height | 1050 mm |