Background: In the attached 1st photo, a set of Wuxi JACK ZHJ8015 model Three in One H Beam Fabrication Machine was being installed in a new workshop at customer facility.

A. The Purpose of ZHJ8015 Integral Function H Beam Welding Machine and Its Workpiece:

1. Function and Great Value of 3 in 1 H Beam Assembly Welding Straightening Machine:

1) This is an efficient and powerful equipment, being applied in steel structure industry;

2) This machine integrates the three core steps in producing welded H Beam/ I Beam/ T Beam, fulfilling the target of raising productivity, maintaining high standard quality level of finished H Beam, as well as reducing period cost and variable cost at customers financial sheet;

2. Welding Technique of 3 in 1 Vertical H Beam Welder:

1) The welding mode in this is SAW (Submerged arc welding), which has large welding current and welding seam size, relative high welding speed, applicable for producing workpieces in large volume;

2) The SAW has working current of 380~ 750A, capacity of up to 1000A, and large welding seam cover:

3) SAW being tested in Wuxi JACK 3 in 1 SAW H Beam Welding Machine: (Fig.1)

3. Applicable Workpieces of 3 in 1 H Beam Welding Line:

1) The welded H Beam/ I Beam/ T Beam manufactured from this machine is the most universal adopted raw materials in steel structure industry. Its most often used sizes have three grades of up to 1500mm/ 1800mm/ 2000mm height, from the smallest size of 200mm;

2) Finished small height welded H Beam produced from Wuxi JACK machine: (Fig.2)

4. Types of Workpieces from 3 in 1 H Beam Fabrication Machine:

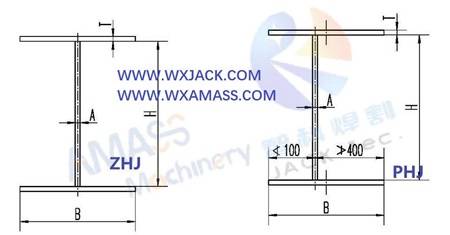

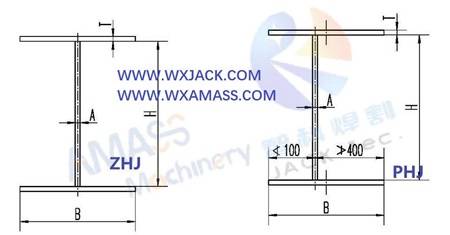

These welded T/ H beams can be classified into two broad categories of:

1) Heavy duty: H Beam flange thickness higher than 40mm, with single piece weight heavier than 8 ton;

2) Light to medium duty H Beams;

With respect to cross section type of H Beam, there are majority of symmetric (Over 70%~ 80%), and minority of asymmetric (Around 20% as the case be);

Symmetric versus asymmetric cross H Beam: (Fig.3)

Of these, ZHJ models (ZHJ8015 model has the largest selling volume) is dedicated for producing symmetric workpiece;

5. Different H Beam Welding Line Applicable on Different Types of H Beams:

1) For producing heavy duty H Beam/ I Beam/ T Beam, the H Beam Production Line, which is composed of three machines for fulfilling Assembling/SAW/Straightening respectively, together with Transferring Carts and Overturning Racks, is the proper equipment;

2) For producing light to medium duty H Beams, the ZHJ series (And PHJ series) Integral Function H Beam Welding Machine is the more proper solution for customers.

B. Constructure of ZHJ Series 3 in 1 H Beam Welding Line:

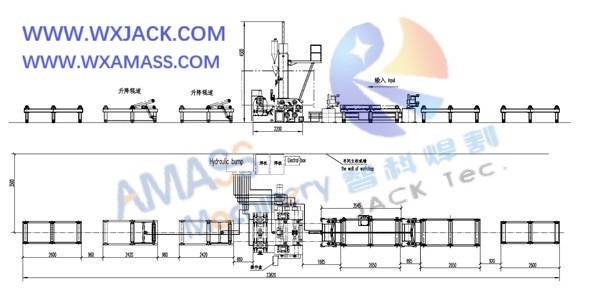

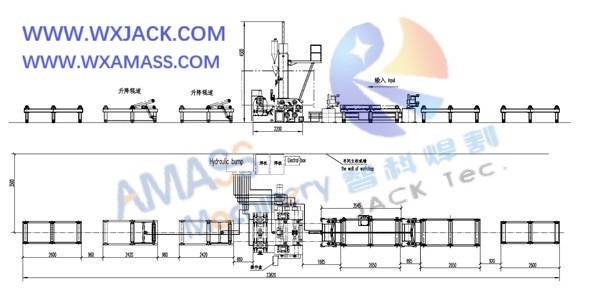

1. Layout Drawing of Wuxi JACK ZHJ8015 model 3 in 1 vertical H Beam Welder Machine: (Fig.4)

As can be found from the above sketch, the working area of this 3 in 1 H Beam Fabrication Machine has land occupation of 28m length by 7m width, which is only 30% that of H Beam Production Line (Please check the production section of “PHJ ZHJ Compact 3 in 1 H Beam Assembly Welding Straightening Machine” on detailed analysis on this topic);

2. Input and Output Conveyor of 3 in 1 H Beam Welding Line:

1) Workpiece Flow: In the layout drawing, the material flow is from right to left. In the attached first photo, it is from inside screen from out of the screen. Or, in the 1st photo the conveyor we see is output conveyor of the H Beam Welder;

2) Manipulator for Pulling on Flange and Web: As can be seen from the layout, there are 2~3 sets of hydraulic drive manipulators deployed along the input conveyor of the machine, depending on length of workpiece:

Hydraulic drive manipulator being deployed along input conveyor: (Fig.5)

3) Working Way of Manipulator: The attached 3rd photo was taken on this manipulator and its installed conveyor. When the flange and web are hoisted onto the input conveyor of the 3 in 1 SAW H Beam Welding Machine, these strip plates need to be maintained to its expected orientation (Flange at horizontal orientation, and web in vertical orientation), and aligned with centerline of the machine. The hydraulic drive manipulator here plays this role;

Assembling H Beam along input roller table with hydraulic drive manipulators: (Fig.6)

3. Mechanical Main Body of 3 in 1 H Beam Assembly Welding Straightening Machine:

1) The mechanical base bed: (Fig.7)

2) And inverted U gantry beam (The attached 5th photo) and below: (Fig.8)

Construct mechanical main body of the machine. These 2 assemblies are the core part of the equipment, integrating the three working cells of:

1) H Beam flange and web assembling (Fine alignment, fit up);

2) SAW welding;

3) H Beam flange straightening;

In the attached 3rd photo and below, the closet to us is straightening section of the 3 in 1 H Beam Fabrication Machine:

Front view on outlet of mechanical base bed, straightening unit: (Fig.9)

4. Function and Welding Supporting Units of 3 in 1 SAW H Beam Welding Machine:

1) Central Function Zone: Back to the attached 2nd picture of the machine layout. It is suggested to locate the three function units of the machine: Control board/ Hydraulic pump station/ SAW power cell in a row, right next to the main body;

2) These function units need to be managed and monitored during the entire working process of the Pull Through H Beam Welder machine;

3) The welding supporting units, including welding wire feeding mechanism, SAW welding flux sending and recovery, welding flux hopper, as can be seen in the attached 1st photo, are all installed and distributed on upright columns and overhead platform of main body;

4) Running glimpse on SAW H Beam fabrication in Wuxi JACK 3 in 1 H Beam Fabrication Machine: (Fig.10)

5. Ready for work: Finally, with the on position of all the function units of the machine, the entire line will be put into use at customer site. As is shown in the attached 6th photo.

C. Technical Parameters of ZHJ8015 Model 3 in 1 H Beam Assembly Welding Straightening Machine:

Technical Parameter | ZHJ8015 Automatic 3 in 1 SAW H Beam Welding Machine |

H Beam Web | Height: 200 ∼ 1500 mm; Thickness: 6 ∼ 32 mm |

H Beam Flange | Width: 150 ∼ 750 mm; Thickness: 6 ∼ 40 mm |

Workpiece (Welded H Beam) Length | 3 ∼ 15 m (Can be special made) |

Three in one Working Speed of Assembly/ Welding Straightening | Scope: 200∼1200 mm/min.(Stepless, Inverter Control, VFD Working Speed: 500~ 700 mm/min. |

Height of Single Pass Welding Seam | Max. 8~12 mm, flat fillet welding of SAW |

Finished Workpiece | Welded H Beam/T Beam of Symmetric Section shape Only |

Machine Overall Dimension(L×W×H) | 28m × 4m × 4.2m |

Input / Output Conveyor Roller Table | 10~11m length each,3 segments each; Input: Two segments driven with motor, one segment of follower section; Output: The first segment driven with oil cylinder, two segments of follower |

Driving Mode | Assembly/ Straightening: Hydraulic Cylinder Workpiece Traveling: A.C. motor |

Flange and Web Assembling Way | Hydraulic motor and cylinder automatically in-phase |

Welding Mode | SAW (Submerged Arc Welding), Single Arc or Twin Arc |

Welding Current | Working current : 380~ 750A; Up Limit: 1000 A |