A. The Application of 5 Axis 2500/9 Oxy-fuel Flame Large CNC Pipe Intersection Cutting Machine:

The attached 6 photos give vivid presentation on operation of 5 Axis 2500/9 Large CNC Pipe Cutting Machine from different perspectives:

1. Working Station of Large CNC Pipe Intersect Cutting Machine: (Fig.1)

As shown in the above photo, for Large CNC Pipe Cutting Machine (Scope Φ2000mm ~ Φ3000mm), to help operator observing cutting torch (In the air) easily, there is an overhead passage alongside the machine body, for operator walking along the whole length of large diameter pipe;

2. Climbing Ladder as Assist Tool in Large CNC Pipe Intersection Cutting Machine: (Fig.2)

Likewise, after cutting and beveling in the Oxy-fuel Flame Large CNC Pipe Cutting Machine, operating staff need to get access to finished workpiece, sometimes with the help of climbing ladder;

3. Cutting Moment in Large CNC Pipe Cutting Machine: (Fig.3)

The above photo is the snapshot from working video of the Large CNC Pipe Cutting Machine taken at customer site;

4. Summing up, the branch group of Φ2500mm series Oxy-fuel Flame Large CNC Pipe Intersect Cutting Machine (For cutting and beveling pipes with diameter up to Φ2500mm) is the newcomer in product family of CP series Plasma Oxy-fuel CNC Pipe Intersection Cutting Machine, for the purpose of best precisely match between machine specification and workpiece size.

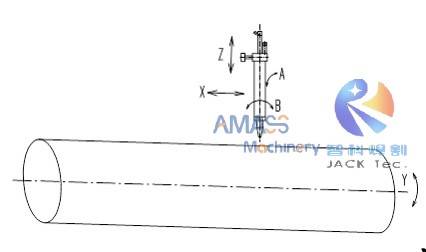

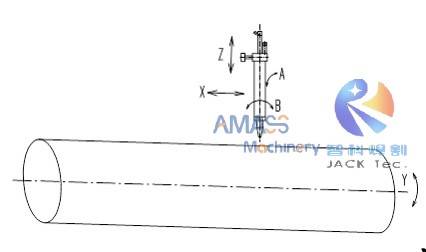

5. The Illustration on 5 Axis in 5 Axis CNC Pipe Cutting Machine: (Fig.4)

B. Development history of Large Oxy-fuel Flame CNC Pipe Cutting Machine:

1. Stage 1: Start up of CNC Pipe Intersect Cutting Machine:

At inception of the equipment, due to the confinement of hardware and software technique, mature product was 3 Axis Φ600mm CNC Pipe Cutting Machine for small pipe cutting;

2. Stage 2: Slant Angle Beveling with 5 Axis to 7 Axis CNC Pipe Intersection Cutting Machine:

The request on precise control on beveling process, for delivery of consistent good quality kerf and groove calls for rise and mature of 5 Axis control technique, and applicable pipe diameter in CNC Pipe Cutting Machine also enlarged to Φ1400mm diameter;

3. Stage 3: Expand to Large Oxy-fuel Flame CNC Pipe Cutting Machine for Processing Large Pipe:

1) With development of technology in the field of Pipeline production, there exists great potential demand on Plasma Oxy-fuel CNC Pipe Intersect Cutting Machine for large pipe (Φ3000 diameter) in many industries, such as Oil and Gas, Pressure Vessel, etc.;

2) After years of explore, 5 Axis control technique grow mature in design and manufacture of CNC Pipe Intersection Cutting Machine, and is applied to large pipe;

3) Meanwhile, for the large size of Φ3000 diameter and precise control target, 7 Axis control CNC Pipe Intersection Cutting Machine comes into being, together with the application on large pipe;

4. Stage 4: Full Range of Application in CNC Pipe Cutting Machine with the Add on of Φ2000mm and Φ2500mm:

1) The 3 grades of Φ600mm/ Φ1400mm/ Φ3000mm can not 100% precisely meet the demand on CNC Pipe Intersect Cutting Machine perfectly, in terms of workpiece diameter scope;

2) More models for intermediate size of Φ2000mm and Φ2500mm diameter are devised under this background.

C. Technical Parameter of 5 Axis 2500/9 Oxy-fuel Flame Large CNC Pipe Intersection Cutting Machine:

Below is specification of 5 Axis 2500/9 Oxy-fuel Flame Large CNC Pipe Intersect Cutting Machine:

Model Technical Parameter | 5 Axis CNC-CP 2500/9 Oxy-fuel Flame Large CNC Pipe Cutting Machine |

Suitable Diameter Range of Workpiece | 500 ~ 2500 (mm) |

Suitable Max. Length of Workpiece | 9000 (mm) |

Suitable Thickness Range of Workpiece | 6~100 mm for flame cutting; 3 ~ 25mm for plasma cutting |

Cutting Speed in Oxy-fuel and Plasma | 200∼800mm/min. for flame cutting Around 200~ 2000mm/min. for plasma cutting (Based on thickness of Pipe and Plasma Power) |

CNC Control Axis | 5 Axis of X/Y/Z/A/B X Axis: For cutting torch positioning along pipe length; Y Axis: For pipe CW/CCW rotation; Z Axis: For Moving up and down cutting torch; A Axis: For tilting cutting torch along pipe radius; B Axis: For tilting cutting torch along pipe length |