1. Quick Understanding on ZHJ Series H Beam Assembly Welding Straightening Integral Machine:

1) ZHJ series SAW H Beam Fabrication Machine is an advanced and highly efficient equipment in steel structure industry, applicable for producing light to medium duty welded H Beam T Beam. The produced max. height of single pass fillet welding seam is 12mm;

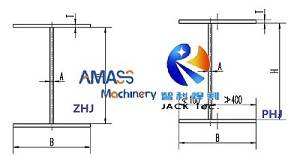

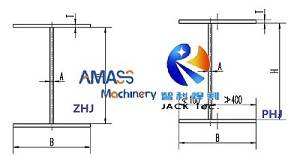

2) ZHJ8020 is the largest model in ZHJ series Vertical H Beam Welder. It manufactures welded H Beam T Beam with web height of 200~ 2000mm: (Fig.1,2)

3) Other specifications of finished steel Beams are same as that of ZHJ8015 and ZHJ8018 models machine.

2. Main Specifications of ZHJ8020 Model Fit Up Full H Beam Fabrication Machine:

1) Welding Mode: SAW (Submerged Arc Welding)

2) Single Pass Weld Toe Size: 8~12 mm

3) Input Conveyor: Total length 11m, into 3 roller tables. One is motor driven

4) Output Conveyor: Total length 11m, into 3 roller tables. The first two can be

Elevated with hydraulic oil cylinder drive

5) Integrated Working Speed of Assembly, Welding and Straightening: 200 ~ 1200 mm/min., A.C. inverter control

6) Total Power of ZHJ8020 Machine: Main frame is 20kW, two sets of welding power is 140KVA

7) Machine Overall Size Length × Width × Height 32m × 4m × 4.2m

3. Main Units of ZHJ8020 Model 3 in 1 Integrated function H Beam Welding Machine:

1) SAW Welding System in ZHJ8020 Pull Through H Beam Welder:

American Lincoln DC1000 Single Arc SAW welding system, or China local brand ZD7-1000IGBT PRO type SAW welding system;

2) A.C. Variable Frequency drive system: Renowned brand inverter;

3) Motor Reducer: Chinese brand

4) Hydraulic system: Chinese brand

4. Technical Features of ZHJ8020 Model 3 in 1 H Beam Fabrication Machine:

As can be check from attached pictures:

In this machine:

a) The first step is rough positioning web and flange, by means of 3 sets of yellow color hydraulic drive manipulators (pulling rod system), deployed along input conveyor roller tables of the machine. See below: (Fig.3)

b) The second step is precise positioning web and flange by means of the 6 pairs of alignment rollers, installed at main frame central working unit of the machine.

In this way, T Beam /H beam is assembled into shape;

2) H Beam Welding in ZHJ8020 Pull Through H Beam Welder:

a) The machine adopts with Single Arc or Twin Arc SAW (Submerged arc welding);

b) The welding power supply can be Chinese brand or U.S. Lincoln, of 1000A ~ 1250A output welding power supplies;

3) Straightening Unit in ZHJ8020 Model 3 in 1 H Beam Fabrication Machine:

H Beam flange straightening unit is installed at outlet of machine main frame, right following assembly and welding units. It straightens on the welded flange with the downward straightening rollers; See below: (Fig.4)

4) Application of the ZHJ8020 Model Vertical H Beam Welder:

ZHJ series machine has bigger market share than PHJ series in Chinese Steel Structure industry. It takes around over 60% selling volume.

5. Technical Parameters of ZHJ8020 Integrated function H Beam Welding Machine:

Technical Parameter | ZHJ8020 SAW H Beam Fabrication machine (Vertical H Beam Welder) |

Web Height Range | 200∼2000 mm |

Web Thickness Range | 6∼32 mm |

Flange Width Range | 150∼750 mm |

Flange Thickness Range | 6∼40 mm |

H Beam T Beam Length | 3000∼15000 mm |

Speed of Assembly, Welding, and Straightening | Integral 200∼1200mm/min.(Inverter Control) |

Size of Single Pass Welding Seam | 8~ 12 mm Height |

Drive Mode | Hydraulic and A.C. Motor |

Input and Output Conveyor | 11m Length respectively |

Machine Overall Size(L×W×H) | 28m×4.2m×5.1m |