ZHJ series 3 in 1 H Beam Assembly Welding Straightening Machine for Steel Structure is developed on the basis of PHJ series machine.

1. Generalization on ZHJ series H Beam Assembly Welding Straightening Machine:

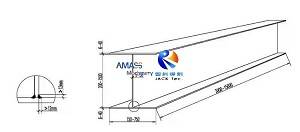

1) Output: ZHJ series 3 in 1 H Beam Fabrication Machine is for manufacturing on welded T Beam/ H Beam of symmetric only flange position with respect to web. (See attached picture);

2) Of which ZHJ8015 model is the smallest standard product, and also with the biggest selling volume. It is for making welding H Beam of web height 200~1500mm;

3) Development Purpose of ZHJ series Fit Up Full H Beam Fabrication Equipment:

a) PHJ series Automatic Integral function H Beam Welding Machine can produce both symmetric and asymmetric flange position with respect to web, which is very versatile;

b) On the other hand, in practical condition, symmetric cross section welded H Beam accounts for majority use, especially in Chinese steel structure industry. Estimation is symmetric cross section welding H Beam takes up around 70% of total consumption;

c) For this reason, based on PARETO theory, Wuxi JACK develop ZHJ series machine, which can meet majority actual demand in market;

4) Strong Points of ZHJ Series 3 in 1 H Beam Assembly Welding Straightening Machine:

a) Financial aspect: Manufacturing cost and quotation on ZHJ series equipment is 5%~6% less compared with PHJ series;

b) Productivity: Benefiting from fully automatic assembling mode, production efficiency of ZHJ series machine can also be raised greatly;

5) Main Function Units of 3 in 1 H Beam Fabrication Machine:

Same as PHJ series , the primary units of ZHJ series machine also include 3 major sections of:

a) Assembly Unit, corresponding with Z15/18/20 models machine;

b) SAW Welding Unit, corresponding with LHC/LHA/LHT series H Beam Gantry Welding Machine;

c) Flange Straightening Unit, corresponding HYJ/YTJ series H Beam Straightening Machine;

6) Operation: In view of operation with operating panel, PHJ series machine is similar to that of PHJ series equipment. Which means, the difference between ZHJ and PHJ models machine only lies in equipment structure, which we will have discussion in the next product of ZHJ8018 model machine. From customers perspective, there is no obvious difference;

7) Labor cost saving from Automatic Integral function H Beam Welding Machine:

With the combination of the above mentioned 3 machines:

a) H Beam Assembly Machine;

b) H Beam SAW Welding Machine;

c) H Beam Straightening Machine,

Operators of ZHJ and PHJ series machine are also reduced from original 6 people to 2 people, let along machine purchase cost reduction and workshop space less;

8) Empirical Data on Wuxi JACK 3 in 1 H Beam Assembly Welding Straightening Machine Straightening Capacity with Respect to H Beam Size:

For Wuxi JACK machine, there is relationship between flange thickness and flange width of H beam that can be straightened as below:

Flange thickness T(mm) | 6~20 | 20~25 | 25~32 | 32~40 |

Flange Width B(mm) | 200~800 | 450~800 | 600~800 | 700~800 |

2. Technical Parameters of ZHJ8015 H Beam Fabrication Machine:

Technical Parameter | ZHJ8015 Model 3 in 1 H Beam Fabrication Machine |

Web Height | 200 ∼ 1500 mm |

Web Thickness | 6 ∼ 32 mm |

Flange Width | 150 ∼750 mm |

Flange Thickness | 6∼ 40 mm |

Workpiece Length | 3000 ∼ 15000mm |

Speed of Welding (Assembly, Straightening) | 200∼1200mm/min. (Variable Frequency Drive) |

Single Pass Welding Seam Height | 8 ~ 12mm |

Machine Overall Dimension(L×W×H) | 28m × 4m × 5.1m |