Subject of This Blog on 3 in 1 H Beam Assembly Weld Straighten Integral Machine:

1) 3 in 1 H Beam Assembly Welding Straightening Integral Machine, or simplified as 3 in 1 H Beam Fabrication Machine, is the new favorite product in Steel Structure Industry, over the past decades;

2) In this short blog, let us have a rapid view on PHJ and ZHJ series Automatic 3 in 1 H Beam Welding Machine, covering the below topics of:

Why So Popular 3 in 1 H Beam Assembly Welding Straightening Integral Machine?

Definition and Outline on 3 in 1 H Beam Fabrication Machine

Market Demand on 3 in 1 Integral Function H Beam Welding Machine

Procedure Sequence of Automatic 3 in 1 H Beam Welding Machine

Summary on Wuxi JACK 3 in 1 H Beam Assembly Weld Straighten Integral Machine

A. Why So Popular 3 in 1 H Beam Assembly Welding Straightening Integral Machine?

1. Functions Combined: As its name suggests, this new generation product of 3 in 1 H Beam Fabrication Machine integrates 3 basic process steps of assembling, welding, and straightening, into one single set of equipment, taking welding as its core function step;

1) Photo View: SAW Submerged arc welding in Wuxi JACK PHJ15 3 in 1 Integral Function H Beam Welding Machine: (Fig.1)

2) Photo View: Welding H Beam produced from Wuxi JACK PHJ 3 in 1 H Beam Assembly Welding Straightening Integral Machine: (Fig.2)

2. Strong Points: In this sense, this Automatic 3 in 1 H Beam Welding Machine takes the place of traditional conventional automatic H Beam Production Line, in the field of light duty and medium duty welding T Beam and H Beam production, saving total cost at least 60% for customers, covering period cost on equipment purchase, variable cost on running and labor, as well as period cost of workshop floor area;

3. Slides: In the web page “Quick Understanding on Wuxi JACK 3 in 1 H Beam Fabrication Machine”, we make list on Wuxi JACK product superiority in intuitive and concise style.

B. Definition and Outline on 3 in 1 H Beam Fabrication Machine:

1. Finished Product: So, what is the integrated Automatic 3 in 1 H Beam Welding Machine? It is a premium tool that can finish the three procedures of setting up, welding as well as correcting the alignment of the same piece of workpiece: T Beam, or H Beam, sometimes we call it I Beam;

2.Photo View: Vertical view on assembly, welding, and straightening units in Wuxi JACK 3 in 1 H Beam Fabrication Machine for H Beam manufacture: (Fig.3)

3. Background and Value: 3 in 1 H Beam Fabrication Machine is the outcome of scientific and technological progress in Welding Machinery Industry, and also is an artifact that boosts manufacturing efficiency, conserves labor, as well as saves manufacturing prices;

4. Focus: There are various models and configurations of assembly welding as well as progressing integrated equipment on several steel account production lines, so today we will speak about 3 in 1 H Beam Assembly Welding Straightening Integral Machine.

C. Market Demand on 3 in 1 Integral Function H Beam Welding Machine:

1. The Widespread Application of T Beam and H Beam from 3 in 1 H Beam Assembly Weld Straighten Integral Machine:

1) Raw Materials: Nowadays, the demand on section steels out there is just boosting, especially for H section and T Section steel, in Steel Structure industry;

2) Critical Role of H Beam: Although there are many kinds of section steels, each sort of the steel has its essential duty, as well as H section steel is no exemption. H shaped steel is considered to be more functional steel. Its form is like the letter H or I, so it is called H shaped steel, or I shaped steel;

3) H Beam Merits: H shaped steel is identified as having the excellent load bearing capability, and also it is much lighter than concrete, so the utilization rate is likewise It is very high, such as our usual bridges, highways, vehicles, trains and ships all have H Beam participation as raw materials. And such large volume usage entails the introduction of 3 in 1 H Beam Fabrication Machine;

2. The Introduction of 3 in 1 H Beam Fabrication Machine into Market:

1) Necessity: The use price of H Beam is very high, so the tools for generating H Beam must equal the times;

2) In many cases, it is a turning around the system. In order to create H shaped much faster as well as better, we made and also created an incorporated Integral function SAW 3 in 1 H Beam Assembly Welding Straightening Integral Machine from the name over, this machine is well recognized;

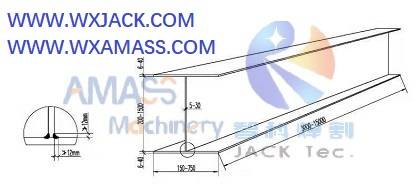

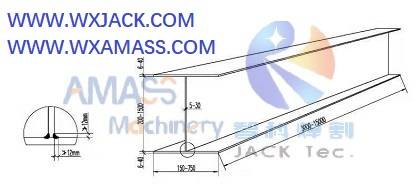

3) The design sketch on typical welding H Beam, that can be produced from Wuxi JACK 3 in 1 H Beam Assembly Weld Straighten Integral Machine: (Fig.4)

3. The Main Units in 3 in 1 H Beam Assembly Welding Straightening Integral Machine:

1) Firstly, we all understand that the forming of H beams calls for three devices in Automatic 3 in 1 H Beam Welding Machine:

a) Constructing device, or assembling cell;

b) Gantry welding, this can be SAW submerged arc welding for making thick plate, or CO2 GMAW for making thin plate;

c) As well as straightening device, for correcting flange after welding;

2) The three pieces of equipment are combined into one set of the 3 in 1 H Beam Fabrication Machine, to create an all-in-one maker, which seems like a combination of robots and also changing them;

3) Photo View: The on site layout and performance of Wuxi JACK PHJ15 Automatic 3 in 1 H Beam Welding Machine: (Fig.5)

D. Procedure Sequence of Automatic 3 in 1 H Beam Welding Machine:

1. Understanding the operating series of the 3 in 1 H Beam Assembly Weld Straighten Integral Machine is not just a responsible representation of the maker's operation, but additionally plays a vital duty in safeguarding the maker's life as well as allowing this 3 in 1 H Beam Fabrication Machine to work better for itself;

2. As a result, in the operation, it is very vital to understand the equivalent links as well as crucial steps realized in the 3 in 1 H Beam Assembly Welding Straightening Integral Machine;

3. Typically speaking, in the department of the major switch of the SAW 3 in 1 Integral Function H Beam Welding Machine, it needs to be gone on;

4. Illumination: At the same time, if the workshop is working at night, the illumination can be turned on, specifically the internal lighting inside the 3 in 1 H Beam Fabrication Machine, which can assist in the specific and also efficient job of the operator and lower the occurrence of blunders;

5. Safe Work: At the same time, check whether the emergency situation quit button is currently in a static state of release, so as to avoid the 3 in 1 H Beam Assembly Weld Straighten Integral Machine from being not able to run after being switched on, leading to a waste of time as well as influencing the tools to a particular extent;

6. Convenient Operation: The procedure of the 3 in 1 H Beam Fabrication Machine screen should recognize and also understand the procedure setting, such as whether the specification setting is in area, whether the hands on mode is turned on, the automatic mode must be activated after the full procedure is steady, and more;

7. Recognizing these series makes the operation of the 3 in 1 H Beam Assembly Welding Straightening Integral Machine growing more comfy.

E. Summary on Wuxi JACK 3 in 1 H Beam Assembly Weld Straighten Integral Machine:

1. Wuxi JACK Leading Role: PHJ and ZHJ series 3 in 1 H Beam Fabrication Machine is the most featured products of Wuxi JACK. We are the first company in the industry to push this product into market, and gained word of mouth from customers;

2. The Main Advantages of Wuxi JACK 3 in 1 Integral Function H Beam Welding Machine can be summarized as:

1) Advanced design and top grade quality;

2) Full line of models and configurations;

3) Lean production for cost effectiveness and quick delivery;

3. For more detail, please visit product section of 3 in 1 H Beam Assembly Welding Straightening Integral Machine.