1. What is Z20 H Beam Assembly Machine Used for:

1) Feature: Z20 manual alignment with automatic CO2 welding H Beam Assembling Machine is the largest one of its product group, output Work In Process welding H Beam with web height up to 2000mm:

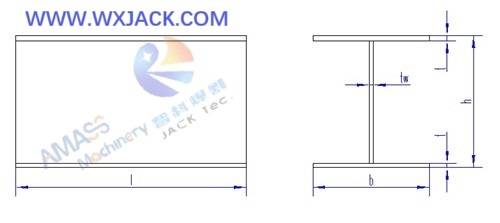

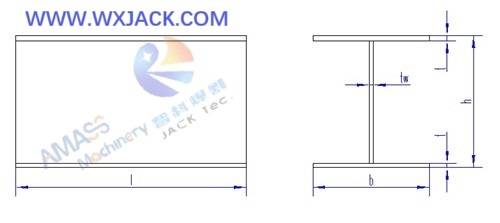

Finished H Beam produced from H Beam Assembly Machine: (Fig.1)

2) Assembly Style: As its name implies, such kind of I Beam Assembling Machine has working way of manual assembly (Manual alignment) and automatic CO2 welding:

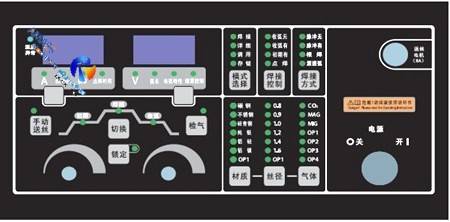

Assembling function group in H I Beam Assembly Machine: (Fig.2)

3) Operating Way: So, in this H Beam Assembly and Tack Welding Machine, first flanges and web are fit up into H Beam with manual adjustment, then strengthened with automatic CO2 welding.

2. Panasonic KR350 CO2 Welding Power Supply applied in H Beam Assembly Machine:

In this product section we will have an introduction on the other option of CO2 tack welding power supply used in H Beam Assembly Machine: Japan brand Panasonic, of KR350 model. As mentioned in the previous product section of “Z18 Manual Alignment H Beam Assembling Machine”, majority of overseas client choose this one when they purchase the automatic H Beam Assembly Machine with Tack Welding:

GMAW Welding power supply equipped in H Beam Assembly and Tack Welding Machine: (Fig.3)

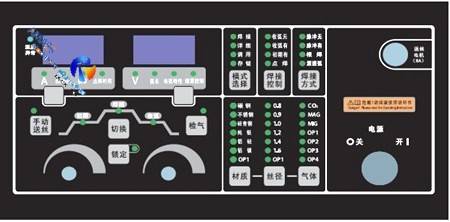

1) Embed Remote Control for Easy Operation in H Beam Assembly Machine: (Fig.4)

Integrate remote control box onto wire feeder. By means of upgraded control circuit, the control cable is diminished from original two pieces to one piece. This makes simple disposition, easy and convenient manoeuvre of cable, and less risk of cable break, in the whole working of H Beam Assembly Machine;

2) High Degree of Dependability for Running of I Beam Assembly Machine:

a) Insulation Grade: H; Main transformer and coil of electric reactor adopt with DuPont Nomex, which has advantages of good dust proof and high temperature proof, protecting the CO2 welding power supply against working environment of H Beam Assembling Machine;

b) Enclosure protection level is IP21S. There is physical isolation between main circuit and control circuit of welding power source. Thus avoid interference of main circuit on control circuit, guaranteeing good protection performance on the aspect of moisture resistance and Anti dripping, making the power source the capability of reliable working at harsh environment, such as that of the Z15/Z18/Z20 H Beam Assembly Machine with Tack Welding;

c) Exclusive patent technology further boosts safety and reliability of the power source;

3) Excellent Welding Process Technology for the H Beam Assembly Machine:

a) The dedicated control circuit can meet the requirement on welding arc dynamic characteristics of CO2/MAG short circuit transition and jet transition, boasts little spatter, during the work of Z15/Z18/Z20 H I Beam Assembling Machine with Tack Weld;

b) Welding Quality: The unique arc striking circuit guarantees 100% success of arc striking under all kinds of working condition, adaptable for working on various welding equipment, such as Z15/Z18/Z20 Automatic H Beam Assembly Machine with Tack Welding;

4) Modulation Unification for the H Beam Assembly Machine:

When making adjusting on current with knob, the matching voltage can be got at the same time; And inching adjustment on voltage is also available;

5) User friendly Operation for the H Beam Assembly Machine:

a) Compatible with both flux wire and solid wire --- In the case of Z15/Z18/Z20 automatic I Beam Assembling machine with Tack Welding, it is flux wire:

Welding power supply equipped in H I Beam Assembling Machine: (Fig.5)

b) Energy saving controller;

c) The magnetic contactor will act 6~7 min. at the completion of welding, cutting off idle input of welding source, and thus reduce idle input loss of the H Beam Assembling Machine;

d) Compensate for network voltage fluctuation—This is very useful on workshop of automated H Beam Assembly Machine;

6) Supplementary Notes for the Z20 Manual Alignment H Beam Assembly Machine:

a) For introduction on automatic CO2 tack welding in the machine, please check product section of “Z18 Self Alignment H Beam Assembly Machine with Automatic Tack Welding”;

b) For comparison on automatic versus manual assembling in the machine, please check product section of “Z15 Manual Alignment H Beam Assembly Machine with Automatic Tack Welding”.

3. Technical Parameters of Z20 Manual Alignment H Beam Assembly Machine:

Below are specifications of this Z20 Manual Alignment High Precision H Beam Assembly Machine with automatic CO2 Tack welding:

Model | Z20 Manual Alignment with Automatic Tack Welding I Beam Assembly Machine |

H Beam Web Width | 200 ~ 2000 mm |

Applicable H Beam Web Thickness | 6∽32 mm |

Applicable H Beam Flange Width | 200 ∽800 mm |

Applicable H Beam Flange Thickness | 6∽40 mm |

Applicable H Beam Length (mm) | 4000∽12000 |

Machine Total Power | 18.7kW + 2 x 12.8 kW |

Input and Output Conveyor Length | 2600 mm x 3 |

Max. H Beam Weight | 20 Ton. |

Web and Flange Alignment Style | Manual Alignment |

Tack Welding Style | Automatic CO2 tack welding |

PLC and Inverter brand | Japan Mitsubishi |

CO2 Welding machine Brand and model | Chinese HUAYUAN NB-350HD, or Japan Panasonic KR350 |