The attached is a set of Wuxi JACK PHJ20 General Purpose 3 in 1 I H Beam Fabrication Machine working on site

A. Usage and Put in Work of PHJ20 I H Beam Fabrication Machine on Site:

1. Finished Workpiece from PHJ Series 3 in 1 I H Beam Welding Machine:

1) Output: PHJ20 I H Beam Assembly Weld Straighten Integral Machine produces welded H Beam/ I Beam/ T Beam of symmetric and asymmetric section shape steel structure members with max. height up to 2,000mm;

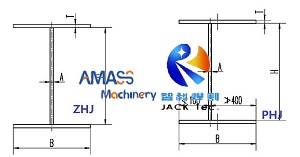

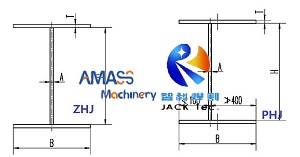

2) The below sketch shows illustration of workpiece made with the PHJ model machine;

3) Welding Mode: It adopts welding mode of SAW--- Submerged arc welding. It is widely used in steel structure facilities because of its wide versatility:

2 types of cross section of finished H (I) Beam from PHJ series machine (Fig.1)

2. Operating on PHJ20 Model 3 in 1 SAW I H Beam Welding Equipment:

1) Raw Materials: As can be seen from the 1st photo, there is a heap of its raw materials (The long strip steel plates cut from CNC Strip Plate Cutting Machine) cumulated right next to the input conveyor of this Automatic H Beam Manufacture Machine. And a piece of strip plate was being put on the input conveyor, which would be taken as flange of workpiece;

2) The operating station of the equipment is at the right hand of its main body, please check the 2nd photo;

3) It is composed of the operating panel of the machine itself, and the 2 control consoles of the SAW power supply;

Operation station of Wuxi JACK 3 in 1 I H Beam Fabrication Machine: (Fig.2)

4) Operating Way: On the control console, welding current/ voltage/ wire feeding speed of the machine can be adjusted before working, and observed during working;

3. Supplementary Welding Units in 3 in 1 I H Beam Fabrication Machine:

The welding support unit of the machine includes:

1) Sintered SAW welding flux recovery unit;

2) SAW welding flux hopper;

3) Diameter 3.2mm to 4.0mm SAW welding wire feeder;

4) SAW welding wire spool;...

Are installed on the mechanical main body of the 3 in 1 I H Beam machine;

Sometimes customer have their welding wire spool put on the ground, as is shown in the 3rd photo. The function units of the Automatic SAW H Beam Welding Machine, including control board/ pump station/ SAW welding power supplies, are put on the workshop ground close to machine main body. As is shown in the 1st photo.

SAW welding wire spool laid on workshop floor of Wuxi JACK I H Beam Assembly Weld Straighten Integral Machine: (Fig.3)

B. Technical View on PHJ20 Automatic SAW I H Beam Welding Machine:

1. Central Working Zone of 3 in 1 I H Beam Fabrication Machine:

1) The attached 4th photo shows central working area of the machine;

2) It was taken at H Beam assembling side (Workpiece flowing in side);

3) In the order of installation are assembling unit/ welding unit/ straightening unit of the machine;

Central working zone of machine: (Fig.4)

2. Assembly Unit of 3 in 1 I H Beam Assembly Weld Straighten Integral Machine:

1) The H Beam assembling unit is for fitting flange and web into the shape of “┷” (When making T Beam) or “工” (When making welded H Beam/ I Beam);

2) The fitting up flanges and web is realized by means of totally 6 pairs of rollers:

--- 3 pairs for clamping web (High up);

--- And 3 pairs for clamping flange (Low position);

3) The driving of these rollers in the machine, as can be seen in the attached 4th photo, are made with guiding brackets and bushings, which, for the flange alignment rollers, the left side is driven with manual leadscrew, and the right side is driven with hydraulic cylinders;

4) The driving way for web alignment rollers are reversed with that of the flange alignment rollers;

H Beam Assembling section of the machine: (Fig.5)

3. SAW Welding Torches of PHJ 3 in 1 I H Beam Welding Machine:

1) The 2 sets of SAW welding torches are execution mechanism for welding operation in the machine, which are controlled with SAW power supplies for its critical parameters of welding current and voltage;

2) Its operation is assisted supporting units of flux recovery unit and wire feeder;

3) The position of the welding torch can be precisely managed by means of cross slides and 45° gliding bracket, to aim at welding seam all the time during welding;

SAW Welding torches in the machine: (Fig.6)

4. Straightening Unit in 3 in 1 I H Beam Fabrication Machine:

1) The straightening unit can be checked in the attached 5th photo;

2) It utilizes the principle of three points squeezing, which, during passing through of the H Beam/ T Beam through the machine, exert force onto the flange by means of the two pieces of downward straightening rollers (Driven with hydraulic cylinder), thus making the workpiece sent out of the machine in straight surface;

3) To adapt to varying flange width of the workpiece to be fabricated in the machine, the span of the two straightening rollers can be adjusted by means of handwheels, which is shown in the attached 5th photo;

Straightening rollers of the machine: (Fig.7)

5. Wuxi JACK Batch Production on 3 in 1 I H Beam Welding Machine:

1) The attached 6th photo shows WIP (Work in process) area of Wuxi JACK 3 in 1 I H Beam Assembly Weld Straighten Integral Machine;

2) Due to its extensive applicability and large selling volume, the PHJ series equipment are always made in volume production.

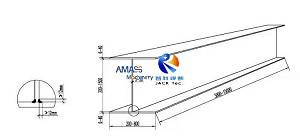

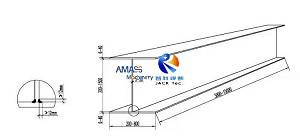

Illustration on finished welded H Beam to be produced: (Fig.8)

C. Technical Parameters of PHJ20 I H Beam Fabrication Machine:

Technical Parameter | PHJ20 General Purpose 3 in 1 I H Beam Fabrication Machine

(I H Beam Welding Machine)

|

Web Size | Height: 200 ∼ 2,000 mm; Thickness: 5 ∼ 30 mm |

Flange Size | Width: 200 ∼ 8,000 mm; Thickness: 6 ∼ 40 mm |

Workpiece (Welding H Beam) Length | 3,000 ∼ 15,000 mm (Can be tailor made) |

Working Speed of Assembly/ Welding Straightening | 0.2∼1.2 m/min.; Working speed 500~700mm/min. (Stepless, Variable frequency drive) |

Welding Seam | Single Pass of max. size 8~12 mm |

Workpiece | Symmetric and Asymmetric Cross Section Shape Welding H Beam/ I Beam/ T Beam |

Overall Dimension of 3 in 1 H Beam Fabrication Machine (L×W×H) | 28m × 4m × 5.1m |

Input and Output Conveyor | 10~11m length in 3 segments each; One with motor, two followers; Input conveyor with 3 sets of hydraulic pulling rod boxes |

Driving Mode | Assembly/ Straightening/ Output conveyor elevation: Hydraulic cylinder |

Welding Mode | Single Arc or Twin Arc SAW at fillet flat position |

Operator | 1 veteran, or 1 operator with an assistant |