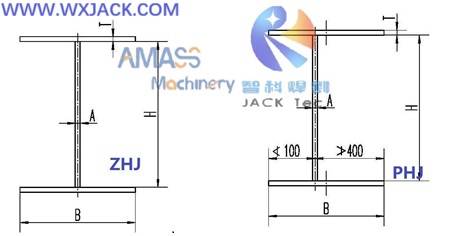

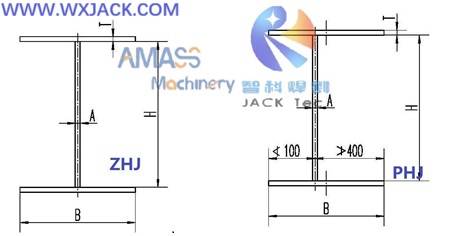

Outline on Usage: PHJ18 model 3 in 1 H Beam Assembly Weld Straighten Integral Machine is for making welded H Beam (I Beam) T Beam with web (wall) height less than 1800mm, of both symmetric and or asymmetric flange position with respect to web. (See attached picture): (Fig.1)

1. Main Units of PHJ18 Model 3 in 1 H Beam Assembly Weld Straighten Integral Machine:

1) H Beam Assembly Unit in H Beam 3 in 1 Machine:

a) Hydraulic drive Pulling Rod System: Depending on length of input conveyor roller table, there are 2~ 3 sets of manipulators, which are driven with oil cylinders, and deployed along input conveyor, for carrying out first stage (rough) alignment and positioning of H Beam flange and web;

b) Automatic Alignment Unit: There are 6 pairs of web alignment rollers (left and right 3 sets each, totally 12 pieces of web alignment rollers) and 2 sets of flange alignment rollers (top and bottom 1 set each, totally 4 pieces of flange alignment rollers) at the working unit of this 3 in 1 H Beam Fabrication Machine, for implementing on final (precise) alignment and positioning of H Beam flange and web (See attached picture);

2) H Beam Welding Unit in 3 in 1 H Beam Welding Machine:

a) Welding System Composition: There are 2 sets of welding power supply, flux recovery system (for SAW only), welding wire feeders in one set of the PHJ18 model machine, welding the 2 seams alongside both sides of H Beam at the same time;

b)In terms of welding mode, it can be either SAW (Submerged Arc Welding) for fabricating medium thickness workpiece, or gas shielded CO2 welding for fabricating thin H Beam. Rule of thumb on the threshold is 12mm thickness;

c) Welding System Brand: Either SAW or CO2 Welding equipped with the machine has several options of brand to choose from: Chinese or overseas supplier;

3) H Beam Flange Straightening Unit 3 in 1 H Beam Fabrication Machin:

There is 1 set of flange straightening unit installed at output outlet side of the machine. It is oil cylinder drive, straightening rollers moving downstroke style, with strong force and easy control;

a) There are 11m length input and output conveyors respectively at the incoming and outcoming side of the machine;

b) Both input and conveyors have three segments of roller table. For input conveyor, one segment is motor drive type, and the other two segments are follower type; For output conveyor, the first two segments are hydraulic drive type for lifting function, to raise up welded H Beam for its cooling down. The 3rd segment roller table is follower type.

2. Technical Parameters of PHJ18 Three in One H Beam Welding Machine:

Technical Parameter | PHJ18 Automatic 3 in 1 H Beam Fabrication Machine |

Welded H Beam Web Height | 200 ∼ 1800mm |

Welded H Beam Web Thickness | 5 ∼ 30mm |

Welded H Beam Flange Width | 200 ∼ 800mm |

Welded H Beam Flange Thickness | 6 ∼ 40 mm |

Welded H Beam length | 3000 ∼15000mm |

Welding Mode and Position | SAW, 0° flat welding, single arc |

SAW Welding Wire | Φ2.5mm ~Φ4.0mm solid wire |

SAW Welding Flux | SJ101 |

Speed of H Beam Assembly/ Welding/ Straightening | 200∼1200mm/min. (A.C. Inverter Control) |

Single Pass Welding Seam Height | 8~12 mm |

Machine Overall Size(L×W×H) | 28m×4m×4.9m |