1. Specialty of 2m Width Hydraulic Edge Rounding Machine:

1) This model of Edge Deburring Rounding machine is applicable for working parts with max. 2000mm width;

2) All the major and core working actions of this Edge Trimming machine are hydraulic drive: Workpiece alignment, workpiece pressing and keeping flat, and workpiece edge rounding;

3) As shown in the attached photos, the mechanical main body of this hydraulic Edge Trimming machine has the frame structure of gantry box;

4) We will introduce this hydraulic Edge Deburring machine from the above two points.

2. Hydraulic System of 2m Width Automatic Hydraulic Edge Rounding Machine:

1) Hydraulic Drive, for Majority of its Movements, Actions and Positioning Operations in Edge Rounding Machine:

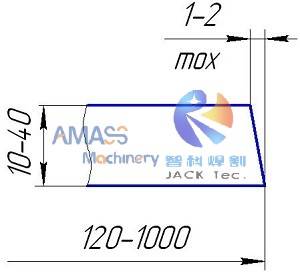

a) At the beginning of operation, rounding rollers travel up and down, based on various thickness of workpiece: (Fig.1)

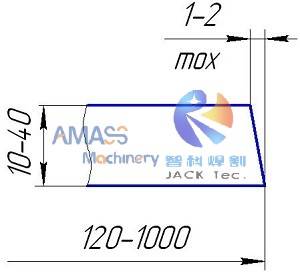

b) Inching adjustment of rounding rollers along horizontal direction to compensate for oblique side of workpiece: (Fig.2)

c) Vertical movement of downward pressing rollers for keeping flatness of workpiece, during operation of the Hydraulic Edge Deburring Rounding Machine: (Fig.3)

d) Acting of side fending rollers at input conveyor of the Edge Rounding Machine, for positioning and alignment of workpiece: (Fig.4)

2) Accordingly, there are 13 pieces of oil cylinders in total in one set of RH2000 Hydraulic End Plate Trimming machine; And all these oil cylinders are controlled with the same set of hydraulic pump station by means of different electromagnetic valves;

3) Deployment of Oil Cylinders in the RH2000 Hydraulic Edge Rounding Machine:

As can be checked from attached and above pictures, that in 1 set of RH2000 Hydraulic Edge Deburring Rounding machine:

a) There are left and right totally 4 sets of oil cylinders for driving the 2 pieces of top rounding rollers along vertical axis at left and right side each;

b) There are left and right 2 sets of oil cylinders for inching adjustment of rounding rollers along transverse way;

c) There are 3 sets of oil cylinders at overhead cross beam of the Edge Trimming machine main body, for driving the 3 pieces of downstroke pressing rollers up and down;

d) There are left and right, at incoming side and outgoing side of the Edge Rounding machine respectively, totally 4 sets of oil cylinders for driving the side fend rollers which are used for positioning and clamping of the workpiece;

These four sections of oil cylinders are in one to one correspondence with respect to the four types of movement mentioned in item 1);

4) The hydraulic system of RH2000 Hydraulic End Plate Trimming machine has total power of 4kW, normal pressure of 7MPa and Max. pressure of 12~14MPa. For its daily maintenance and service, we give detailed introduction in the Edge Rounding machine manual book, and will give training to working staff at customer site.

3. Mechanical Frame of RH2000 Gantry Structure Plate Edge Deburring Rounding Machine:

1) The gantry frame gives the Edge Rounding machine a steady and firm main body, withstanding impact and influence from all the high speed and high power working process of rounding and deburring: (Fig.5)

2) The gantry frame gives the Edge Trimming machine a relatively enclosed working environment, protecting both operators and working units against external interferences;

3) The gantry frame gives the Edge Deburring machine a plain and concise routing of cables, pipelines, and tubes by way of its columns and cross beams;

4) The RH1500 and RH3000 hydraulic Edge Rounding machine has the same structure of main frame as RH2000 introduced here; While RH1000 and smaller models (For example, RH800) have different mechanical frame as RH2000.

4. Technical Parameters of 2m Width Hydraulic Edge Rounding Machine:

Below are specifications of RH2000 Hydraulic End Plate Trimming Machine:

| RH2000 Hydraulic Edge Deburring Rounding Machine |

No. | Item | Parameter |

1 | Suitable Workpiece Width Scope | 150 ~ 2000 mm |

2 | Suitable Workpiece Thickness | 10 ~ 40 mm |

3 | Suitable Workpiece Length | 1000 ~ 12000 mm |

4 | Suitable H Beam Min. Web Beam Height | 320 mm |

5 | Rounding and Deburring Speed | 7200 mm/min. |

6 | Finished Rounding Radius | R2.5 mm |

7 | Main Rounding Rollers Diameter | φ300 mm |

8 | Power of Hydraulic Pump Station | 4 kW |

9 | Max. Pressure of Hydraulic System | 12 MPa |

10 | Input and Output Conveyor Length | 10m each |

11 | Total Power of Edge Rounding machine | 10.6 kW |

12 | Power Specification | 380V, 50Hz, 3P |