A. Function and Usage of HGK8 Leadscrew Adjusting Driving Welding Pipe Rotator:

1. Task for Completion in the Welding Pipe Rotator:

1) This Welding Roller Rotator are used for rotating pipes in the range of 0° to 360°,

2) And performing automatic welding at the same time, in the manufacture stage of pipe working parts and components;

2. Applicable Working Parts Dimensions Suitable for Pipe Welding Rotator:

1) Diameter of the pipes ranges from Φ200 - Φ800 mm;

2) Length of the pipes is up to 12,000mm;

3) Thickness of pipe wall S equals to 10 mm;

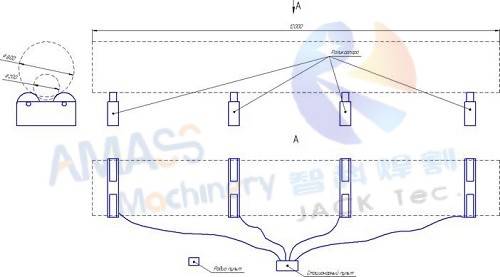

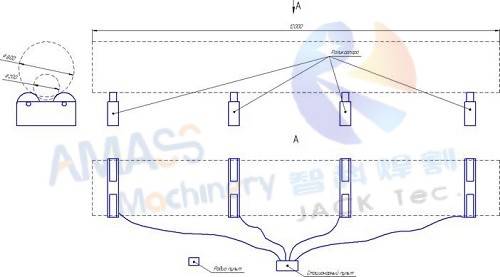

3. Vertical planar graph on workpieces in the HGK8 Pipe Welding Rotator: (Fig.1)

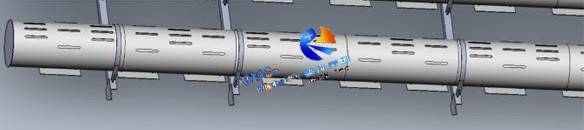

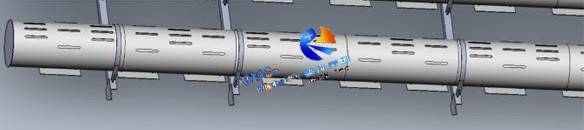

4. 3D design model on finished pipes fabricated from HGK8 Welding Rotating Turning Roll: (Fig.2)

B. Structures and Configurations of HGK8 Welding Rotating Roller Support:

1. Composition: This working complex of HGK8 Welding Pipe Rotator is composed of 4 sets of individual driving Welding Rotating Roller Bed;

2. Working Nature: Each set of the Welding Rotating Roller Support is of leadscrew adjusting structure, in motorized driving style;

3. Loading Capacity of the HGK8 Pipe Welding Rotator:

1) Each set of the Welding Rotating Turning Roll has loading capacity of 2000kg, in other words, 2 Ton individually;

2) So, totally the 4 sets of Welding Rotating Roller Support adds up to 8 ton loading capacity, for the working complex of HGK8 Pipe Welding Rotator;

4. Photo View: The arrangement of Wuxi JACK HGK8 Welding Rotating Roller Support in a row: (Fig.3)

C. Technical Requirement on HGK8 Leadscrew Adjusting Pipe Welding Rotator:

1. Driving Style in HGK8 Welding Pipe Rotator:

1) Each of the 4 sets of the Welding Rotating Roller Support should be equipped with motorized driving Rotating Turning Roll, to ensure uniform rotation of the workpiece (pipe) at a given speed;

2) Each of the 2000kg loading weight motorized Welding Roller Rotator: (Fig.4)

3) In all, 1 set of the Welding Pipe Rotator consists of four pieces of individually located Welding Rotating Roller Support;

2. Rotating Turning Roll in the Leadscrew Adjusting Welding Pipe Rotator:

1) The Welding Rotating Turning Roll should be coated with a layer of polyurethane, to increase and maintain sufficient gripping force on the rotating product: (Fig.5)

2) Loading capacity of each of the leadscrew managing Welding Rotating Turning Roll: kg - min 2000 kg;

3. Electric Control in the HGK8 Leadscrew Adjusting Pipe Welding Rotator:

1) According to the diagram shown in below, the control board and operating panel should be located on the sliding panel near the Welding Roller Rotator:

2) General layout of the 4 groups integrating HGK8 Welding Pipe Rotator: (Fig.6)

3) Uniform Revolving: The radio panel and control board should ensure uniform rotation of all Pipe Welding Rotator, both together and individually, at a given speed;

4) Position Management: The connection and positioning of the Welding Rotating Roller Support, is made depending on the length of the product, ranging from 500 mm to 12000 mm;

5) The Welding Roller Rotator conveyors should be connected to the stationary unit and have an independent connection to each other, i.e. one, two, three or four roller conveyors can be connected to the Pipe Welding Rotator general control board at the same time.

D. Welding Rotating Turning Roll Working Speed Management in the Welding Roller Rotator:

1. Rotating Speed Range: The rotation drive should provide smooth adjustment of the pipe rotation speed, ranging from 100 mm/min up to 1000 mm/min.;

2. Control and Display: This rotating speed is controlled by means of A.C. inverter, equipped with real time digital display;

3. The Actual Operating Welding Rotation Speed Specification in Welding Pipe Rotator:

1) Effective welding working rotating speed varies from min. 100 mm/min. to max. 500 mm/min.;

2) Idle rotation speed varies from min. 500 mm/min. to max. 1000 mm/min.;

3) These working and idle rotating speed should be adjustable during working period of the Pipe Welding Rotator;

4. Control element panel inside control board of Wuxi JACK Welding Pipe Rotator: (Fig.7)

E. Operation Way in the 4 Rotating Roller Support Integration HGK8 Welding Pipe Rotator:

1. Managing on Welding Roller Rotator:

Every group of is controlled by means of

1) 1 piece of stationary control operating panel;

2) And 1 piece of manual control panel, in radio control manner;

3) The operating controller (Remote control) applied in Wuxi JACK Welding Roller Rotator: (Fig.8)

2. Functionality of Buttons and Switches on Both Stationary and Remotes in the Welding Pipe Rotator:

1) The toggle switch for clockwise vs. counterclockwise rotation direction of the Welding Rotating Turning Roll;

2) Button to start on rotation;

3) Rotation speed adjustment;

4) Emergency stop for contingency protection;

5) Idle button, which means without welding;

6) Welding start button, for turning on and off welding operation;

7) Welding operation stop;

8) Welding speed indicator, which equals to rotating speed of the Rotating Turning Roll;

3. Welding Mode and Operation in HGK8 Leadscrew Adjusting Welding Pipe Rotator:

1) Welding Center: This working complex of HGK8 Welding Pipe Rotator should be synchronized with an external welding power supply, for implementing mechanized welding with a melting electrode in shielding gas (MIG, MAG). This accomplishes setting up Welding Center in flexible fashion;

2) Interlink with External: Such interlinked working with external units is initiated, when the start button is turned on: Rotation and welding on, in the HGK8 Pipe Welding Rotator;

3) Working Speed Show: The speed indicator should be on the stationary console and on the handheld console in mm/min., giving intuitive indication, for ease of management by operators on running condition monitor;

4) Precondition for Normal Running: All the equipment in the Welding Pipe Rotator, including driving motor/ gearbox/ cables..., should not interfere with the rotation of the products on the Welding Rotating Roller Support.