A. The Task and Finished Product of Automatic Production Steel Structure H Beam Machine:

1. Just as its name suggests, this machine is used for producing welded H Beam/ T Beam with the conventional dimensions of:

1) Height (Web, or Wall) is from 200mm to 1500mm/ 1800mm/ 2000mm;

2) Width (Flanges, or Shelf) is from 200mm to 800mm;

3) Wall thickness (Flange and web) is from 6mm to 40mm;

2. Wuxi JACK Competitive Edge on Providing Automatic H Beam Production Machine:

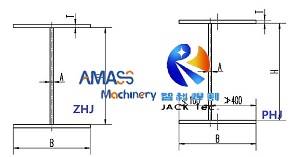

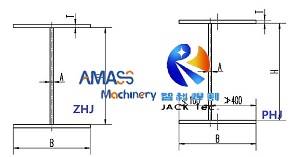

1) You can even make cross section of H Beam/ T Beam in asymmetric structure produced from Wuxi JACK machine, as shown in below sketch: (Fig.1)

2) The finished product: Welded T Beam delivered from Wuxi JACK ZHJ15 model 3 in 1 Steel Structure H Beam Machine: (Fig.2)

2) The finished working parts: Welded H Beam delivered from Wuxi JACK ZHJ18 model Integral Function H Beam Welding Machine: (Fig.3)

B. The Function and General Working Steps in PHJ and ZHJ Series 3 in 1 Automatic H Beam Production Machine:

To produce finished product of welded H Beam/ T Beam from strip plates, 3 major steps need to be completed in sequence:

1. The First Assembly Step: Assembly in 3 in 1 H Beam Assembly Welding Straightening Integral Machine:

1) Function: This step completes on fitting up 2 pieces of flange and 1 piece of web into the constructure of H Beam;

2) Acting Sequence: The fitting up of flanges with web involves action of: Working parts positioning  Alignment → Clamping, which needs heavy force of hydraulic drive;

Alignment → Clamping, which needs heavy force of hydraulic drive;

3) Working Manner: Considering the long length of raw materials (Flange and web) and relative long time for its feeding in and assembly, which should be reliable and accurate, there are 2 stages of assembling in the machine:

a) The first stage for H Beam assembly: Hydraulic drive manipulators deployed at input conveyor roller table of Wuxi JACK ZHJ10 model Three in One H Beam Fabrication Machine: (Fig.4)

b) The second stage for H Beam assembly: Hydraulic drive 6 pairs of alignment rollers at central zone of the Steel Structure H Beam Machine: (Fig.5)

4) Role Playing: This assembling step of 3 in 1 H Beam Assembly Welding Straightening Integral Machine is counterpart of Z15/18/20 model H Beam Assembly and Tack Welding Machine, but remove the CO2 tack welding step, contributing outstanding cost down brough along with the PHJ and ZHJ machine;

2. The Second Step H Beam Fabrication: Welding Operation in 3 in 1 H Beam Assembly Welding Straightening Integral Machine:

1) Task: In this step, 2 pieces of mirror arranged welding torches implement finished welding on both sides of workpiece;

2) Importance: This step determines welding seam quality of finished product. This is the why this Steel Structure H Beam Machine is often called “Integral Function H Beam Welding Machine”;

3) Welding Mode in Integral Function H Beam Welding Machine:

a) Majority SAW: Most of the welding is in the form of SAW (Submerged arc welding), which accounts for over 95% in application of the 3 in 1 machine;

b) Sometimes GMAW: In minority conditions, to produce small size and thickness welded H Beam, such as web has thin wall of 6~ 10mm only, large current SAW is not applicable. By this time, you should make choice on GMAW CO2 gas shielded welding instead;

4) Role Playing of Welding Step in 3 in 1 Automatic H Beam Production Machine:

a) Welding cell in the machine is counterpart of LHA and LHT / LHC series H Beam Welding Machine;

b) The difference is, in LHA/ LHT/LHC series H Beam SAW Welding Machine, welding torch moves back and forth several times to deliver large size welding seam;

c) While in this PHJ and ZHJ models 3 in 1 machine, welding torch only performs one pass welding. This is the reason why PHJ and ZHJ series machine only produces small to medium duty H Beam, with welding seam not exceeding 12mm;

d) Welding torch distribution and operation in Wuxi JACK Automatic Production Steel Structure H Beam Machine: (Fig.6)

3. The Third Step: H Beam Flange Straightening of 3 in 1 H Beam Assembly Welding Straightening Integral Machine:

1) Task: In this step, the upper and lower pieces of flange will be flattened out to eliminate the deformation made from heat input;

2) Role Play: This unit finishes the task of HYJ&YTJ series H Beam Flange Straightening Machine;

3) Wuxi JACK Competitive Edge: The straightening capacity of Wuxi JACK machine is 40mm, compared with only 20mm by competitors;

4) Straightening system and its operation in Wuxi JACK 3 in 1 H Beam Machine: (Fig.7)

C. Technical Parameters of PHJ and ZHJ 3 in 1 H Beam Fabrication Machine:

Technical parameter | PHJ15/ 18/ 20 | ZHJ8015/ 8018/ 8020 |

| Automatic H Beam Production Machine |

Web height | 200∼1500/ 1800/ 2000 mm | 200∼1500/ 1800/ 2000 mm |

Web thickness | 5∼30mm | 6∼32 mm |

Flange width | 200∼800mm | 150∼750mm |

Cross Section Structure | Symmetric and Asymmetric | Symmetric only |

Assembling Way | Semi-Automatic, hydraulic oil cylinder with manual turning leadscrew | Automatic, hydraulic oil cylinder in mirror |

Flange thickness | 6∼40 mm |

Work-piece length | 3000∼15000mm |

Single Pass Welding Seam Height | 8 ~ 12 mm |

Welding Speed (Assembly, Straighten same) | 200∼1200mm/min.(VFD) |

Machine size(L×W×H) | 28m×4m×4.6m | 28m×4m×4.9m | 28m×4m×5.1m | 28m×4m×4.2m | 28m×4m×4.5m | 28m×4m×4.8m |

Working Mode | Material Handling: By hand; Assembly/ Weld/ Straighten: Automatic; Workpiece pass through |