A. Outline on (LHZ2030 Welding Column and Boom + HGK5 Welding Rotator) as Cylinder Body Workpiece Submerged Arc Welding Center:

1. Function of the Submerged Arc Welding Center:

1) This Welding Center is for carrying out circumferential seam welding and longitudinal seam welding on cylindrical working parts, in the mode of SAW (Submerged arc welding);

2) Number of circumferential seam welding on the finished workpieces is in the range of 20 to 100 circles;

3) Max. diameter of cylindrical workpieces applicable for this Submerged Arc welding machinery group is Φ2000mm, in the length of 3000mm, and 5 Ton weight;

2. Composition of the Submerged Arc Welding Center:

This Welding Center is composed of:

1) One set of LHZ2030 Moving trolley Welding Column and Boom;

2) One set of HGK5 Leadscrew Adjusting Welding Rotator;

3) One set of MZ-1000 Submerged Arc Welding Power Supply, and its control console;

4) Integrated electric Control System of the Welding Manipulator and Welding Roller Bed;

All of the above listed main units are integrated together, to be formed into an integral group of Submerged Arc Welding Center, boosting with convenient operation.

B. Technical Characteristics of Welding Center with LHZ2030 Welding Column and Boom with HGK5 Welding Rotator:

1. The LHZ2030 moving trolley Column and Boom welding machinery has motor drive trolley base;

2. Under motor drive, horizontal boom of this moving capability manipulator welding machine can be elevated along vertical direction, and moved back and forth along horizontal direction, fulfilling tasks of longitudinal seam and circumferential seam welding;

3. Longitudinal Seam Welding with the Moving Welding Manipulator:

The lateral movement of horizontal boom, which is also the welding speed for longitudinal seams on workpieces, is A.C. inverter controlled;

4. Circumferential Welding with Cooperation between Welding Column and Boom, and Leadscrew Adjusting Welding Roller Bed:

1) The circumferential seam welding on cylindrical workpieces should be performed together with running of Welding Rotator: During revolve of workpieces on its Welding Roller Bed, also the revolving linear speed is welding velocity on circumferential seam welding, which is controlled with inverter;

2) Position of SAW Welding Torch at Welding Manipulator: (Fig.1)

The submerged arc welding torch of the Welding Center is installed at front end of the horizontal boom, together with welding seam tracker, control console, and wire feeder:

3) Before operation, make adjustment on position of welding torch, to make it aiming at welding seam on the workpieces perfectly, and start on the HGK5 Leadscrew Adjusting Welding Rotator for workpiece rotation. Then the circumferential seam welding on cylindrical workpieces can be started in the Submerged Arc Welding Center.

C. Structure and Characteristic of LHZ2030 Moving Welding Column and Boom:

1. Overall View on the LHZ2030 Moving Welding Manipulator:

1) This set of LHZ2030 moving Column and Boom welding machine mainly consists of upright column, horizontal boom, cross saddle and moving trolley, shown as below:

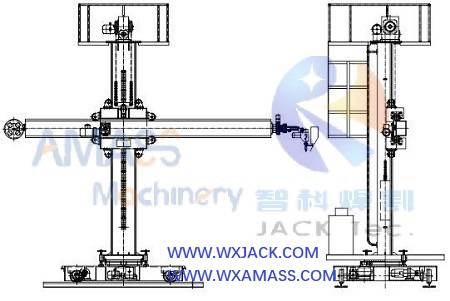

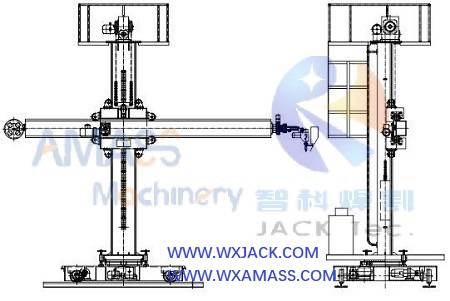

2) Mechanical Structure Sketch on Wuxi JACK LHZ2030 Moving type Welding Manipulator: (Fig.2)

2. Trolley Moving of the LHZ2030 Welding Column and Boom:

1) This Column and Boom welding machinery is movable trolley type: It has motorized moving trolley, to lead the entire set of equipment moving on the railway;

2) The corresponding moving speed is constant;

3. Column Revolve in the LHZ2030 Moving Welding Manipulator:

1) The upright column can be rotated by manual operation;

2) Its revolving transmission is fulfilled by means of high precision slew ring: (Fig.3)

4. Horizontal Boom Transverse Movement in the LHZ2030 Welding Column and Boom:

1) By the transmission of gear and rack couple, the leftward and backward movement of the horizontal boom features in high precision and accurate positioning;

2) The adopted gear reducer is produced by professional supplier, of which lubrication is oil immersed enclosed style, eliminating invasion of slag, dirt, particle, thus bringing forth advantages of maintenance free and long life;

3) Mechanisms for Horizontal Boom Movement: (Fig.4)

5. X and Y Axis Boom Movement Guiderails in the LHZ2030 Welding Manipulator:

1) Rectangle cross section shape rails are used on both upright column and horizontal boom;

2) These high accurate rails are planed and grinded post annealing, guaranteeing stability during welding;

3) The heavy duty high precision guiderails in Wuxi JACK Column and Boom welding machine: (Fig.5)

D. Electric System of the Submerged Arc Welding Center:

1. The control system is integral style, mainly composed of control cabinet and pendant. See attached and below photos:

2. Operating pendant of the Moving Welding Manipulator: (Fig.6)

3. The control board inside the control cabinet has contactor, control transformer, A.C. inverter, and terminals on it; This unit mainly serves as controlling on and off of motor, performing motions of the Welding Center, and implementing on protection of the motor.

4. Operation: By means of the control cabinet and pendant, all the sections of the Submerged Arc Welding Center, Welding Column and Boom, Welding Roller Bed can be operated separately, also various parameters can be adjusted on practical condition, realizing integral control with welding system of the entire group Welding Center.

E. Technical Parameters of the LHZ2030 + HGK5 Submerged Arc Welding Center:

1. LHZ2030 Moving Welding Column and Boom:

No. | Parameters | Value | Note |

1 | The Max. Vertical Moving Stroke of Horizontal Boom: | 2000mm |

|

2 | The Max. Horizontal Moving Stroke of Horizontal Boom: | 3000mm |

|

3 | Horizontal Boom Horizontal Moving Speed | 120~1200 mm/min |

|

Adjustment of Horizontal Boom Horizontal Moving Speed | Inverter adjust | Schneider |

4 | Horizontal Boom Vertical Moving Speed | 1000 mm/min | Constant |

5 | Horizontal Boom Horizontal Direction Movement Transmission | Gear and Rack |

|

6 | Horizontal Boom Vertical Direction Movement Transmission | Chain and Sprocket |

|

7 | Cross Slides stroke for Welding Torch Adjustment | Vertical and Horizontal 100mm | Inching Adjustment |

8 | Welding Seam Tracker Unit | One set | ED-ST50 |

9 | Video Monitor System | One set |

|

11 | Type of Column and Boom Welding Machine | Movable trolley, column rotate |

|

12 | Span of the Moving Manipulator Welding Machine Trolley Rail | 1600mm |

|

2. HGK5 Leadscrew Adjusting Welding Rotator:

Model | HGK5 |

Max. Loading Capacity of Welding Roller Bed | 5.0 tons |

Range of Workpiece Diameter | d | 300 mm |

D | 2000 mm |

Turning Roll Diameter And Width | Rubber Roller | D1 | 250 mm |

W3 | 100 mm |

Metal roller | D2 | 244 mm |

W4 | 20 mm |

Rotating Linear Speed | 100-1000 m/min. |

Way of Rotation Speed Control | VFD Inverter |

Power of Rotating Driving Motor | 550W *2 sets |

Welding Rotator Installation Size |

| L | 1800 mm |

W3 | 600 mm |

H | 590 mm |

Distance between Turning Rolls (mm) | A | 280-1200 mm |

Weight of Welding Rotator | 1100 kg |