1. Purpose of HJ-200 Length Direction H Beam Straightening Machine:

1) HJ-200 is another heavy tonnage model of HJ series Length Direction Straightening Machine second only to HJ-300: (Fig.1)

2) For its accommodating workpiece size and machine parameter, please check previous product section of “HJ300 Length Direction H Beam Straightening Machine”.

2. Application of HJ-200 Length Direction H Beam Straightening Machine?

1) HJ-300 and HJ series Length Direction I Beam Straightening Machine:

We have covered topics of:

a) Usage and application scope;

b) Longitudinal straightening principle;

c) Empirical data on match between pressure tonnage of machine and workpiece size;

Of the HJ series Length Direction Straightening Machine. This machine has highlight of universal coverage on workpiece type, not confined to H Beam only;

2) In this section of HJ200, we will give introduction on operating process of the HJ series Length Direction H Beam Straightening Machine.

3. Working Process of HJ series Length Direction H Beam Straightening Machine:

1) Workpiece Feed in and Send out of the Length Direction Straightening Machine:

a) HJ series Length Direction Straightening Machine does not straighten the workpiece in continuous way, but intermittently instead --- Segment by segment slong the entire length of workpiece;

b) To start the operating process, press the button, conveyor will drive the workpiece forward, sending the workpiece certain distance and then stop;

c) Then begin straightening operation on this segment of the workpiece in the Length Direction Straightening Machine;

d) At the completion of straightening this segment, the machine conveyor roller table works again to drive the workpiece going forward another segment, for next round of straightening process;

2) Workpiece Straightening Step in the Length Direction H Beam Straightening Machine:

Please check picture as below. Let’s review on:

Mechanical main frame (Central straightening unit) of the Length Direction Straightening Machine: (Fig.2)

a) Point 3 is for applying force, which is a press unit driven with hydraulic system;

b) Point 1 and 2 are force bearing side, composing three points subject to force, for straightening operation together with Point 3;

c) Distance between Point 1 and 2 can be adjusted, based on workpiece size of the Length Direction H Beam Straightening Machine, and deflection condition of the workpiece;

d) This distance is adjusted in this way: Both Point 1 and 2 can be moved along guideway of the beam, and fixed in position with bolts; Please check below picture:

Straightening length adjustment block of Lengthwise H Beam Straightening Machine: (Fig.3)

3) Operation of HJ Series H Beam Length Direction Straightening Machine:

a) Another important mechanism of the HJ series machine is Ejector one and two, which are used for pushing the workpiece away from beam at the finish of straightening;

b) Conceivably, during the straightening process, the workpiece is held against the beam firmly. For the ease of transporting workpiece forward, this step is realized with a toggle switch on pendant (Check below);

c) The critical control point of straightening process is moving stroke of Point 3, or pressing head, during straightening process. To have precise management on it, there is ruler installed at the top section of this acting unit, please check below picture:

Straightening stroke control unit in Lengthwise H Beam Straightening Machine: (Fig.4)

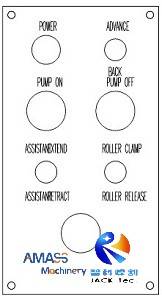

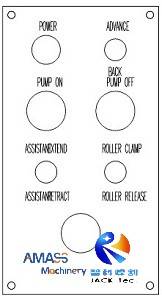

4) Operating Pendant of the HJ Series H Beam Length Direction Straightening Machine: (Fig.4)

With the above description it is easy to understand usage of each button/ switch on operating pendant of the machine:

a) POWER - Indicating lamp on power on/ off of the machine;

b) ADVANCE / BACK – Toggle switch to control conveyor roller table;

c) PUMP ON – Button to start on the hydraulic oil pump work;

d) PUMP OFF - Button to shut off the oil pump;

e) ASSISTANT EXTEND / ASSISTANT RETRACT - Toggle switch to manipulate the Ejector one and two;

f) ROLLER RELEASE / ROLLER CLAMP - Toggle switch to activate forward and backward of the pressing head;

g) EMERGENCY STOP – For contingency control of the Length Direction H Beam Straightening Machine;

h) For machine structure and main component we will talk about it in next section of HJ100 hydraulic automatic Length Direction H Beam Straightening Machine.