A. Application Field of 6 Axis 1400/9 High Precision Automatic Programming CNC Pipe Intersection Cutting Machine:

1. The attached first photo gives good example on applicable operating site of 6 Axis 1400/9 High Precision CNC Pipe Cutting Machine: (Fig.1)

1) This medium sized CNC Pipe Cut Equipment is suitable for processing medium diameter workpieces, with diameter up to Φ1400mm, length up to 9m;

2) One Piece Only: There is one piece of short length (Around 3~4m) pipes laid on supporting friction rollers of the CNC Pipe Cutting Machine. Although its length does not occupy the full length of the CNC Pipe Cut Equipment, based on control logic of the machine, it is recommended that at any moment there is only single piece of pipe to be cut, in this High Precision CNC Pipe Intersection Cutting Machine;

3) Other Equipment: There is a group of traveling Welding Rotator in the distance. These all belong to equipment for pipe fabrication and production;

2. In terms of background, here the model of 6 Axis 1400/9 is derivative product of 6 Axis 1400/12 Flame and Plasma CNC Pipe Cutting Machine, which has 3000mm shorter valid cutting stroke along pipe length direction against the latter model.

B. Operation of 6 Axis 1400/9 High Precision Automatic Programming CNC Pipe Cutting Machine:

1. Workstation in Automatic Programming CNC Pipe Intersection Cutting Machine:

1) In the product section of 7Axis 2500/9 CNC Pipe Intersection Cutting Machine, we mentioned 2 types of operating stations equipped in these High Precision CNC Pipe Cut Equipment:

2) Floor standing type and Cantilever type Operation Station in CNC Pipe Cutting Machine: (Fig.2)

3) Correspondingly, because of powerful function control software in CNC system, the arrangement of buttons and switches on operating panel of the CNC Pipe Cutting Machine is relative simple and concise: (Fig.3)

2. The User Friendly Operation on HMI (Human machine interface) in Automatic Programming CNC Pipe Cutting Machine:

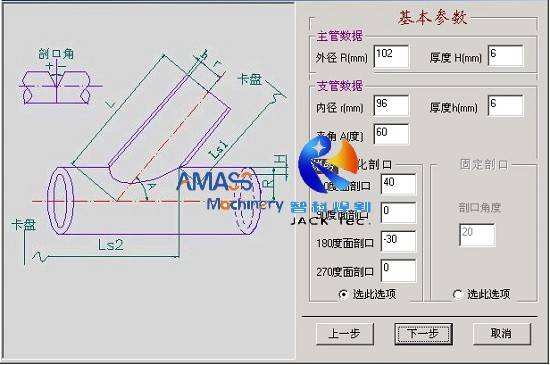

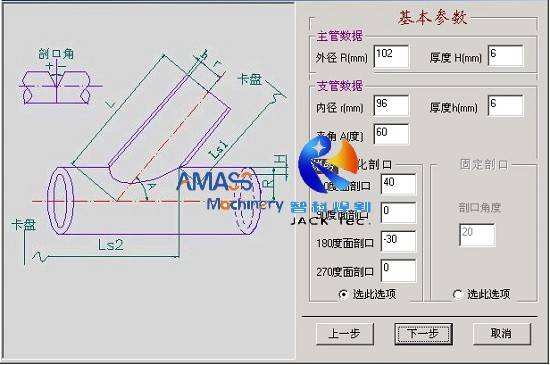

Below is screen shot on HMI, together with corresponding operation tips in this Automatic Programming CNC Pipe Cut Equipment: (Fig.4)

There is a professional workpiece library built in at the industrial computer of the Automatic Programming CNC Pipe Cutting Machine. Its operation is intuitive and real time control:

1. Key in the library data for workpieces of the CNC Pipe Cutting Machine:

1) Select the corresponding workpiece thru the library;

2) Input parameters of the pipe;

3) Cutting program is created automatically;

2. Position of the pre-cut at the initiation of CNC Pipe Cutting Machine work:

1) The control system adds on lead-in automatically;

2) Then pierce a hole at the scrap of pipe automatically, guaranteeing smooth and non-slur surface of curved pipe;

3. Turning of angle in High Precision CNC Pipe Intersection Cutting Machine:

1) For 0° of turning angle, the pipe will be cut right above;

2) When turning angle is 180°, the pipe will be revolved 180° automatically for cutting;

4. From above we can see that, operation of the CP series Oxy-fuel CNC Pipe Intersection Cutting Machine is plain and user friendly.

C. Technical Parameters of 6 Axis 1400/9 High Precision Automatic Programming CNC Pipe Cutting Machine:

Below is specification of 6 Axis 1400/9 Flame and Plasma High Precision CNC Pipe Cut Equipment:

Model Technical Parameter | 6 Axis CNC-CP 1400/9 High Precision Automatic Programming CNC Pipe Intersection Cutting Machine |

Applicable Diameter Range of Workpiece (mm) | 300 ~ 1400 |

Applicable Max. Length of Workpiece (mm) | 9000 |

Applicable Thickness of Workpiece (mm) | 6~100 mm for flame cutting 3 ~ 25mm for plasma cutting |

Applicable Cutting Speed of Oxy-fuel and Plasma | 200∼800mm/min. for flame cutting Around 200~ 2000mm/min. for plasma cutting (Based on thickness of Pipe and Plasma Power) |

Effective CNC Control Axis | 6 Axis of X/Y/Z/A/B/V X Axis: For cutting torch move along workpiece longitudinal; Y Axis: For pipe rotation; Z Axis: Based on various pipe diameter; A Axis: For controlling cutting torch tilting along pipe diameter; B Axis: For controlling cutting torch tilting along workpiece lengthways; V Axis: For cutting torch move along workpiece radius |