A. The Origin of 7 Axis 2000/12 High Precision Flame and Plasma CNC Pipe Intersection Cutting Machine:

1. Different from the model of 3 Axis 600/12 CNC Pipe Intersecting Cut Machine, which is the first model developed in the product family of CP series Flame and Plasma CNC Pipe Cutting Machine, here the this product section 7 Axis 2000/12 Flame and Plasma High Precision CNC Pipe Cutting Machine is the latter and recently developed product;

2. This model is the supplement on the models of 7 Axis 1400mm CNC Pipe Cutting Machine specification, and 7 Axis 3000mm High Precision CNC Pipe Intersecting Cut Machine: Maintain the same complicated control of 7 axis in CNC system, the 2000mm specification model bridge the gap for this range of medium size workpiece pipe diameters;

3. Before the development of 7 Axis 2000mm specification High Precision CNC Pipe Intersection Cutting Machine, the model of 1400mm specification was for medium sized pipe, and 3000mm specification was for large sized pipe. Now, with the refinement on models of Flame and Plasma CNC Pipe Cutting Machine, the 2000mm specification model is developed for this further customer segmentation.

B. The 7 Axis in the 7 Axis 2000/12 High Precision Flame and Plasma CNC Pipe Cutting Machine:

1. The attached photos give working moment, as well as finished cutting kerf, from the CNC Pipe Intersecting Cut Machine:

1) Cutting and beveling with swing of torch in the 7 Axis CNC Pipe Cutting Machine: (Fig.1)

2) Finished ellipse edge in pipe cut from the Flame and Plasma CNC Pipe Intersection Cutting Machine: (Fig.2)

2. For the definition on the 7 Axis controlled with industrial computer of CNC Pipe Intersection Cutting Machine, let us review it here again:

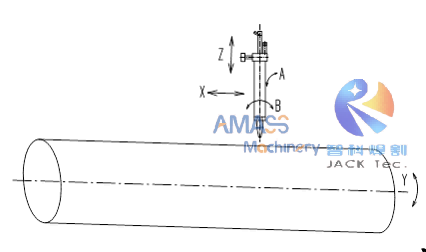

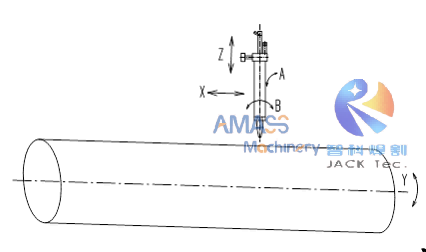

Of the 7 Axis X/Y/Z/A/B/W/V, 5 of them are interlocked during running of the High Precision CNC Pipe Intersection Cutting Machine: (Fig.3)

1) Cutting torch up and down (Z Axis);

2) Cutting torch swing along radial direction of pipe (A Axis);

3) Cutting torch swing along axial direction of pipe (B Axis);

4) Cutting torch move along radial direction of pipe (V Axis);

5) Cutting torch move along axial direction of pipe (X Axis);

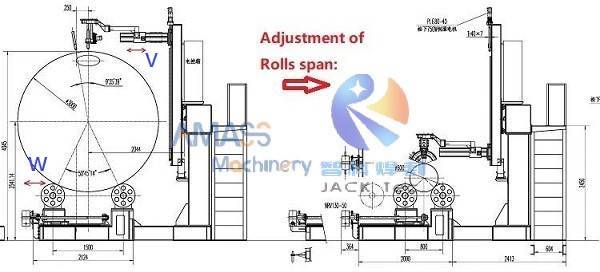

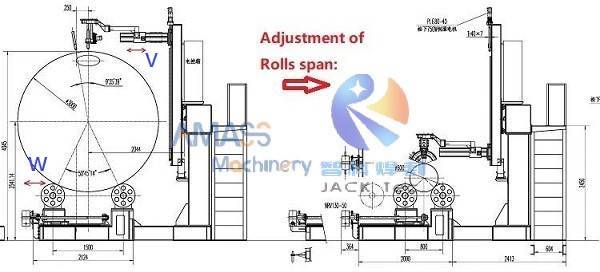

These 2 axis are controlled individually during work of the CNC Pipe Intersecting Cut Machine: (Fig.4)

6) Turning rolls move along radial direction of pipe (W Axis);

7) Pipe rotation (Y Axis)

C. How to Cope with Deformation on Round shape Cross Section of Pipe, in High Precision CNC Pipe Cutting Machine?

1. As we know, in daily running of the Flame and Plasma CNC Pipe Intersection Cutting Machine, it is inevitable that there are sometimes workpieces with cross section not completely round. This will bring along negative impact on performance of the CNC Pipe Cutting Machine;

2. To solve or avoid this issue, there is an Anti-collision device equipped on the CNC Pipe Intersection Cutting Machine, for the purpose of protecting cutting torch against bumping on the surface of pipe, in case the pipe does not have cross section of regular round shape;

3. During operation of the High Precision CNC Pipe Intersecting Cut Machine, this device touches on the pipe during cutting, and if the cross section of the pipe is not a perfect circular, the Z axis vertical control of cutting torch will regulate the cutting torch into moving up and down, to avoid colliding with the pipe.

D. Technical Parameters of 7 Axis 2000/12 High Precision Flame and Plasma CNC Pipe Intersection Cutting Machine:

Below is specification of 7 Axis 2000/12 Flame and Plasma High Precision CNC Pipe Cutting Machine:

Model Technical Parameter | 7 Axis CNC-CP 2000/12 High Precision Flame and Plasma CNC Pipe Cutting Machine |

Fitting Diameter Range of Pipe For Cutting and Beveling (mm) | 400 ~ 2000 |

Fitting Max. Length of Pipe For Cutting and Beveling (mm) | 12,000 |

Fitting Thickness of Pipe For Cutting and Beveling (mm) | 6~100 mm for flame cutting; 3 ~ 25mm for plasma cutting (Depends on specific model of plasma power supply) |

Fitting Cutting Speed during Flame Cutting, or Plasma Cutting | 200∼800mm/min. for flame cutting Around 200~ 2000mm/min. for plasma cutting (Based on thickness of Pipe and Plasma Power) |

CNC Control Axis | 7 Axis of X/Y/Z/A/B/V/W X Axis: Cutting along lengthwise of pipe; Y Axis: Pipe revolve; Z Axis: Cutting torch elevation; A Axis: Cutting torch tilts along lengthwise of pipe; B Axis: Cutting torch tilts along radius of pipe; V Axis: Cutting along radius of pipe; W Axis: Roller Span |